- Overview

- Recommended Products

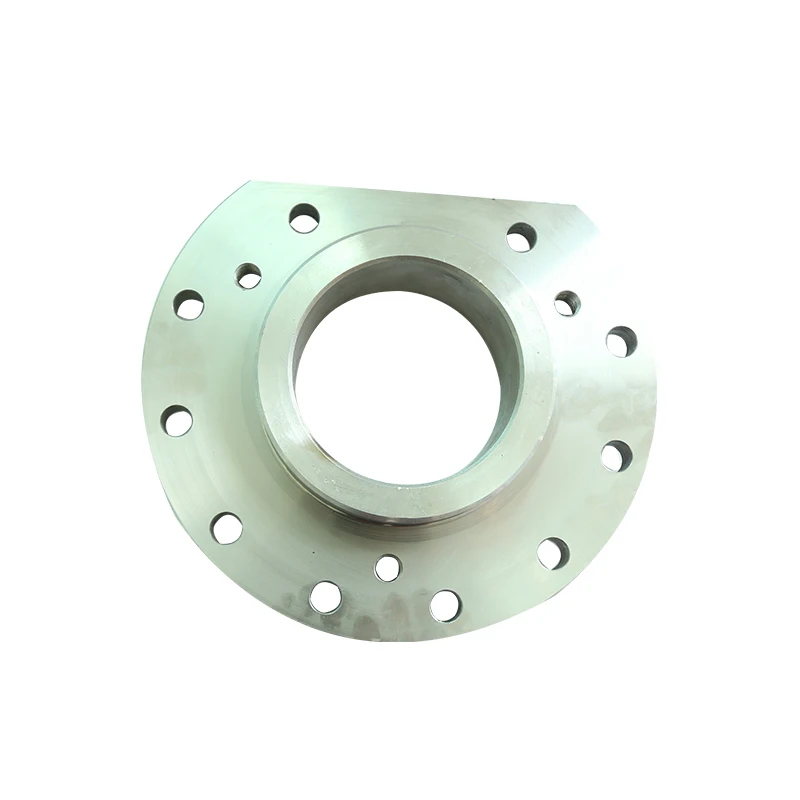

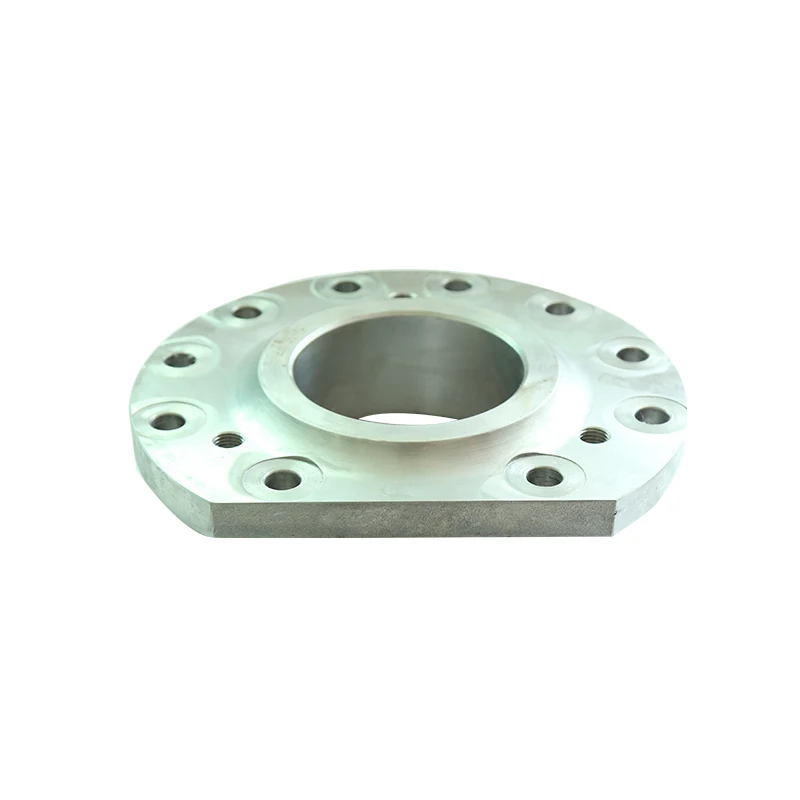

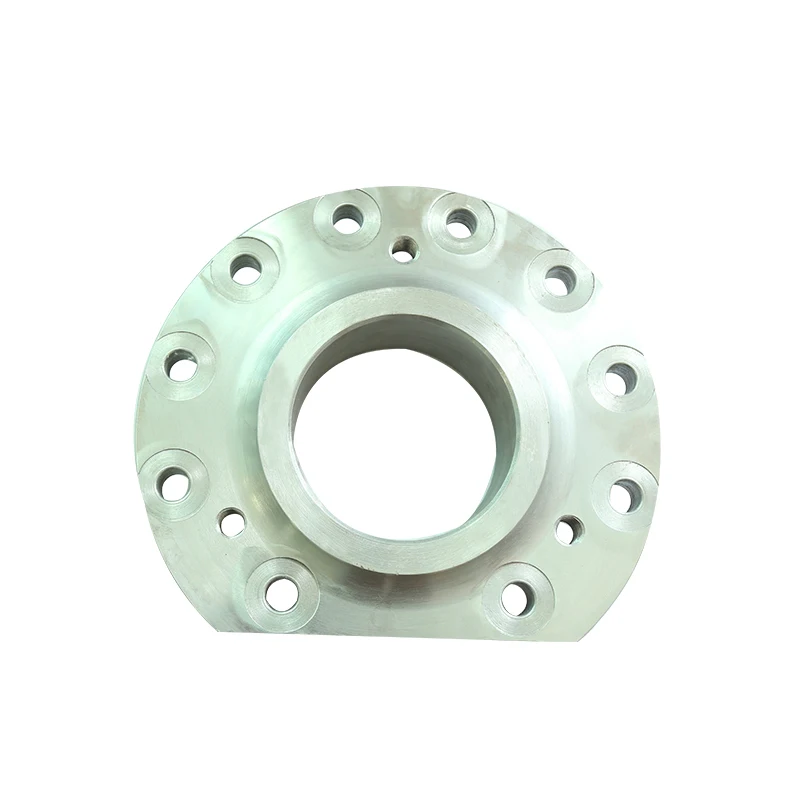

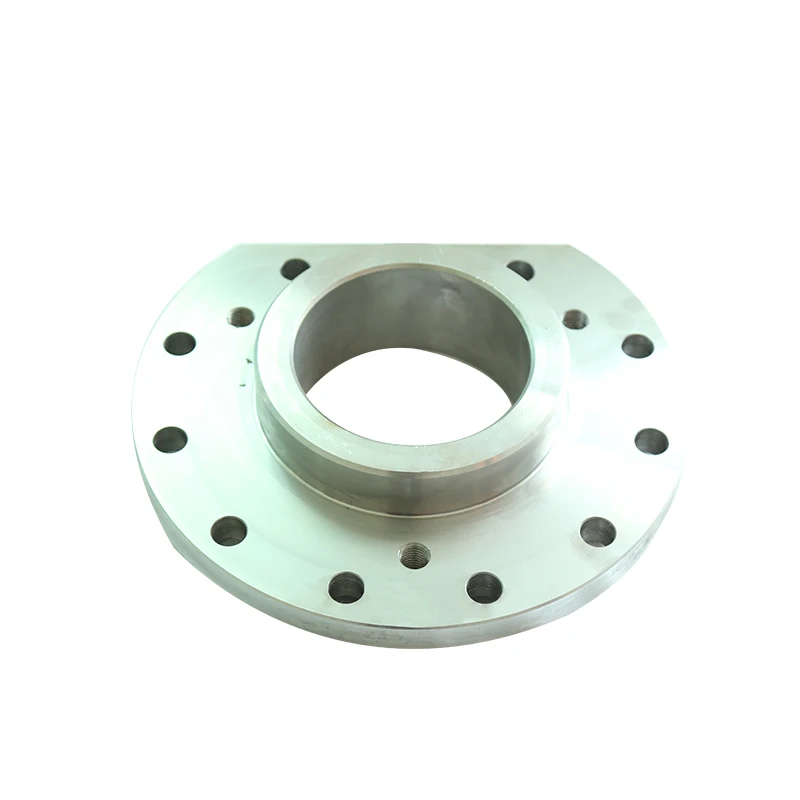

In the competitive world of automotive and specialty vehicle manufacturing, the wheel hub is a critical safety component that demands uncompromising strength, corrosion resistance, and dimensional precision. As a leading China-based manufacturer, our stainless steel wheel hub casting services deliver superior alternatives to traditional materials, combining the inherent benefits of stainless alloys with advanced foundry technology for exceptional performance and aesthetic appeal.

Premium Stainless Steel Alloys for Demanding Applications

We specialize in high-performance stainless steels selected for their optimal balance of strength, ductility, and environmental resistance:

Austenitic Grades (304, 316): Provide excellent general corrosion resistance and good mechanical properties, ideal for commercial vehicles and marine applications.

Martensitic Grades (420, 17-4PH): Offer higher strength and hardness through heat treatment, suitable for high-load and performance-oriented applications.

Precipitation-Hardening Grades (17-4PH): Deliver the best combination of high strength and corrosion resistance for racing and aerospace applications.

All materials undergo rigorous spectrographic analysis to ensure chemical composition meets international standards (ASTM, DIN, JIS).

Advanced Manufacturing Process

Our integrated production system ensures consistent quality from molten metal to finished product:

Investment Casting Process: Delivers near-net-shape components with excellent surface finish and dimensional accuracy, minimizing machining requirements.

Shell Molding Technology: Suitable for larger production runs, providing good dimensional stability and cost efficiency.

Precision Machining: Full CNC machining capabilities for critical bearing surfaces, bolt holes, and mounting features with tight tolerance control.

Comprehensive Heat Treatment: Solution annealing, quenching, and tempering processes to achieve required mechanical properties.

Key Performance Advantages

Superior Corrosion Resistance: Withstands road salts, chemicals, and environmental exposure far better than carbon steel alternatives.

High Strength-to-Weight Ratio: Provides structural integrity while managing unsprung weight.

Excellent Impact and Fatigue Resistance: Withstands dynamic loads and cyclic stresses throughout service life.

Enhanced Safety Margin: Consistent material properties and manufacturing quality ensure reliable performance under extreme conditions.

Aesthetic Versatility: Polished or brushed finishes maintain appearance without additional coatings.

Quality Assurance Protocol

Liquid penetrant testing for surface defect detection

Radiographic inspection for internal quality verification

Dimensional validation using CMM technology

Mechanical property testing and material certification

Dynamic balance testing for rotational components

Industry Applications

High-performance automotive and racing vehicles

Commercial truck and trailer applications

Marine and coastal environment vehicles

Specialized industrial and agricultural equipment

Luxury and custom vehicle builds

Our commitment to technological excellence and quality control makes us the preferred partner for OEMs and Tier-1 suppliers worldwide. We maintain IATF 16949 quality management certification and support full traceability requirements. Contact our engineering team to discuss your specific wheel hub requirements and discover how our stainless steel casting expertise can enhance your product performance and reliability.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |