- Overview

- Recommended Products

In the intricate networks of industrial fluid and gas systems, the integrity of every connection is critical. For OEMs and project engineers demanding reliability, our China factory specializes in producing customized CNC machining Ductile Cast Iron Tee fittings. These components are engineered to provide superior strength, leak-proof performance, and long-term durability, making them an optimal choice for demanding piping infrastructures across various sectors.

Premium Material: Ductile Cast Iron

The exceptional performance of our Tee fittings begins with the material itself. Ductile Cast Iron, or nodular iron, is renowned for its enhanced mechanical properties over standard cast iron, due to its unique spheroidal graphite microstructure. This structure grants the material:

High Tensile Strength and Impact Resistance: Withstands high internal pressures, water hammer, and external loads without cracking, preventing catastrophic system failures.

Good Ductility: Exhibits a degree of elongation, allowing it to absorb stress and deformation beyond the yield point, a safety feature gray iron lacks.

Excellent Machinability: The graphite nodules create discontinuous chips, facilitating smooth and precise CNC machining of complex profiles and threads.

Superior Damping Capacity: Effectively absorbs system vibrations, reducing noise and protecting connected equipment.

Precision Manufacturing Process

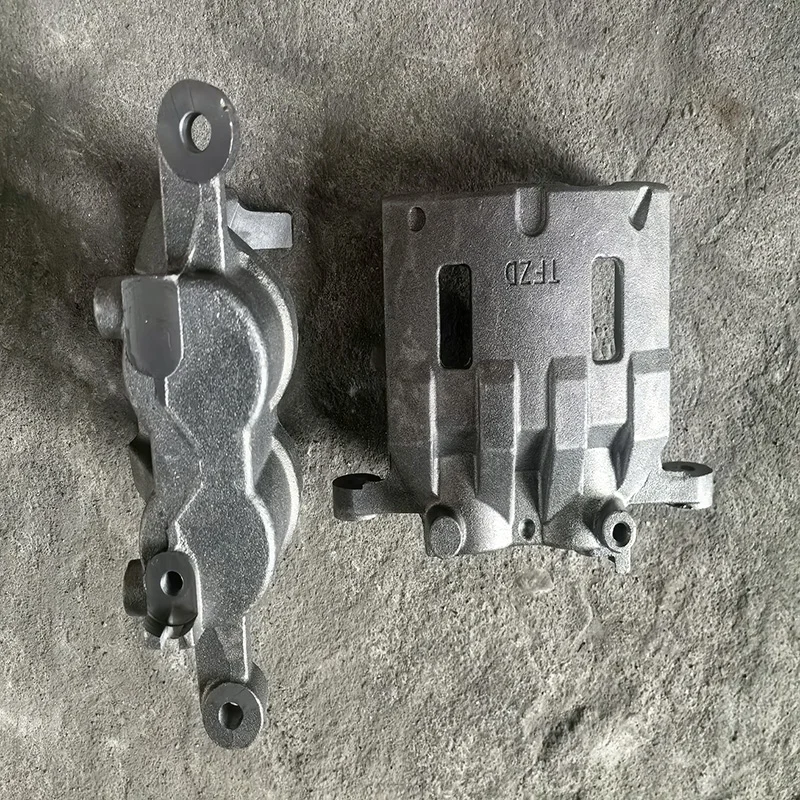

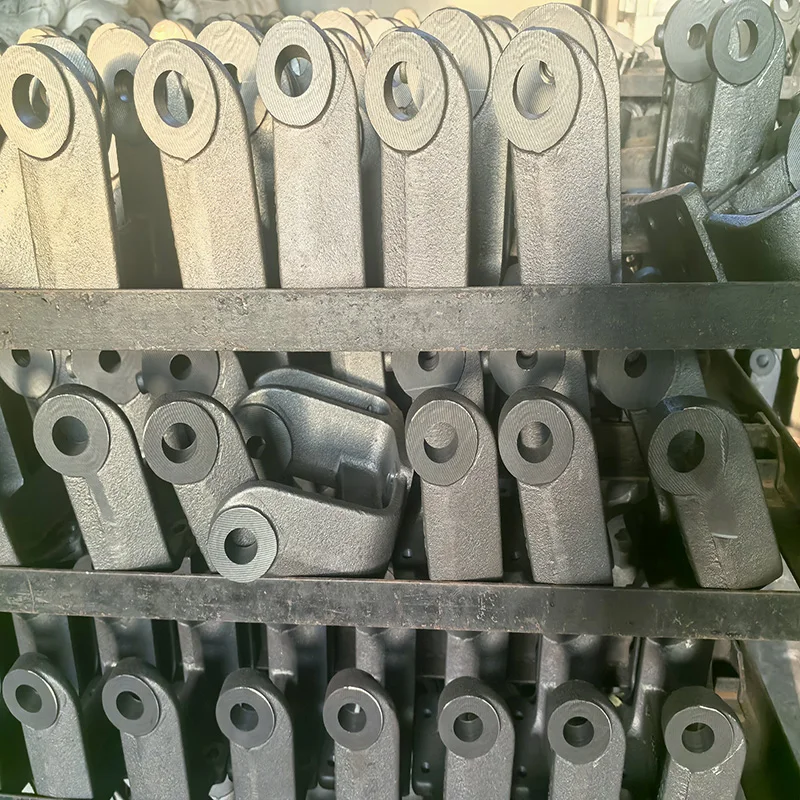

Our manufacturing process is a two-stage, precision-driven operation ensuring every Tee fitting meets exact specifications:

High-Quality Casting: We begin with high-integrity sand casting to produce a near-net-shape Ductile Iron Tee blank. This process ensures a dense, homogeneous structure with excellent mechanical properties.

Precision CNC Machining: The raw casting is then transformed on advanced CNC machining centers. This critical stage machines the sealing faces to a perfect finish, precisely bores the inner diameters, and cuts accurate threads (e.g., NPT, BSPT, BSPP) to ensure a perfect, leak-tight connection with other piping components. This level of customization guarantees dimensional accuracy and interchangeability.

Key Advantages and Customization

The synergy of Ductile Iron and CNC machining offers significant benefits:

Leak-Free Performance: Precision-machined sealing surfaces ensure reliable, long-term seals.

Dimensional Accuracy and Interchangeability: Customized to meet specific project standards and dimensions.

Extended Service Life: Resists wear, corrosion, and pressure fatigue, reducing maintenance and replacement costs.

Wide-Ranging Industrial Applications

Our Customized Ductile Iron Tees are vital in numerous applications, including:

Water and Wastewater Transmission

Oil and Gas Pipelines

Fire Protection Sprinkler Systems

Industrial Plumbing and HVAC

Chemical Processing Plants

Secure your piping systems with components built for performance and longevity. Contact our China factory today to discuss your customized CNC machining Ductile Cast Iron Tee requirements and receive a professional quote tailored to your project's needs.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |