- Overview

- Recommended Products

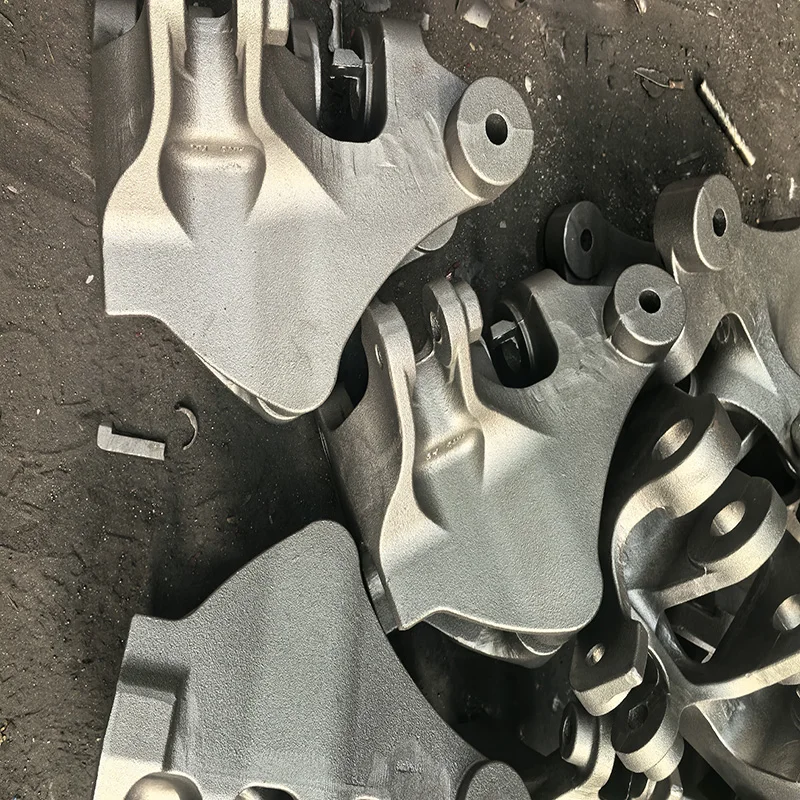

As the global manufacturing hub for industrial components, China has established unparalleled expertise in producing high-quality ductile iron sand casting products. Our foundry specializes in manufacturing ductile iron components using advanced sand casting technology, delivering products that combine exceptional mechanical properties with cost-effective production. These components serve critical functions across multiple industries where strength, durability, and reliability are non-negotiable requirements for operational success.

Material Excellence and Performance Characteristics

We utilize high-grade ductile iron (GGG40/50/60 per DIN 1693, equivalent to 400-18/500-7/600-3) specifically engineered for demanding applications. Our standard GGG50 ductile iron provides tensile strength of 500 MPa minimum, yield strength of 320 MPa, and elongation of 7%, offering the optimal balance between strength and ductility. The nodular graphite microstructure delivers exceptional impact resistance (Charpy values of 12-20 J at 20°C) and superior fatigue strength, capable of withstanding dynamic loading conditions. The material's excellent vibration damping capacity – approximately five times greater than steel – ensures quiet operation and reduced stress transmission throughout assembled systems.

Advanced Sand Casting Manufacturing Process

Our manufacturing employs state-of-the-art green sand casting with automated molding lines that maintain dimensional consistency across production volumes. The process begins with simulation-optimized pattern equipment designed to achieve proper feeding and solidification characteristics. Controlled magnesium treatment and post-inoculation ensure consistent nodularization throughout the casting sections. Each component undergoes precision machining on CNC equipment, maintaining dimensional tolerances within ±0.005 inches per inch and surface finishes of 3.2-12.5 μm Ra depending on application requirements. Our comprehensive quality system includes spectrographic analysis, mechanical testing, ultrasonic inspection, and dimensional verification to ensure every casting meets specified standards.

Comprehensive Industrial Applications

China's ductile iron sand casting products serve essential functions across global industries including automotive components (brake calipers, suspension parts), agricultural machinery (tractor transmission cases, implement gears), construction equipment (hydraulic cylinder blocks, machinery bases), and industrial machinery (pump housings, valve bodies, gearbox cases). The wind energy sector utilizes our castings for turbine hubs and frame components, while the mining industry specifies our products for crusher parts and equipment components subjected to extreme abrasive wear. Our manufacturing capabilities accommodate component weights from 1 kg to 2000 kg, supporting both high-volume production and specialized single components.

Partner with China's manufacturing expertise for ductile iron sand casting products that combine metallurgical excellence with competitive pricing. Our comprehensive approach from pattern making to finished machining ensures components that enhance equipment performance, reduce maintenance costs, and provide reliable service across diverse applications, supported by complete quality documentation and international material certifications.

Product Name |

Non-standard Custom Aluminum Bell Housing Sand Casting Parts |

Quality Assurance |

ISO9001:2015 Certified |

Material

|

Aluminum Alloy: 5052 /6061/ 6063 / 2017 / 7075 / etc. |

Brass Alloy: 3600/ 3602 / 2604 / H59 / H62 / etc. |

|

Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc. |

|

Steel Alloy: Carbon Steel / Die Steel / etc. |

|

Other Special Materials: Nickle / Titanium Alloy / etc. |

|

We handle many other type of materials. Please contact us if your required material is not listed above. |

|

Surface Treatment |

Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting |

Inspection |

Caliper, Inner diameter micrometer, OD diameter, Height Vernier Caliper, Hardness Tester, Ring Gauge, Infrared Spectrometer, Profile Projector Machine, Coordinate Measuring Machine, Roughness Meter, etc. |

File Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Machining Equipment |

Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. |

Application |

Agriculture Machinery: Cylinder Heads, Oil Pump, Clutch Housing, Steering Box

Denfense: Blank Receiver, Trigger Guards

Heavy Machinery: Rock breaker, Bearing Housings

Mining: Chippers blades, Impellers, Wear Rings, Gear Housings

Oil Gas: Gate Valve, Wellhead Control EQP, Wellhead EQP

Transportation:Cylinder heads,Engine support,Intake manifolds,Suspension arm

|

Standard |

ASTM, ASME, DIN, JIS, ISO, BS, API, EN,GB |

Capability |

Output 120 tons per month. |

Company Advantage |

1. Quotation within 48 hours.

2. Quality you can rely on.

3. Zehan provides 100% satisfaction at world competitive prices.

4. We pay meticulous attention to details throughout the whole manufacturing process.

5. Rigorous QC standards, 100% inspection before shipping.

6.Strict delivery time control for each and every order.

|