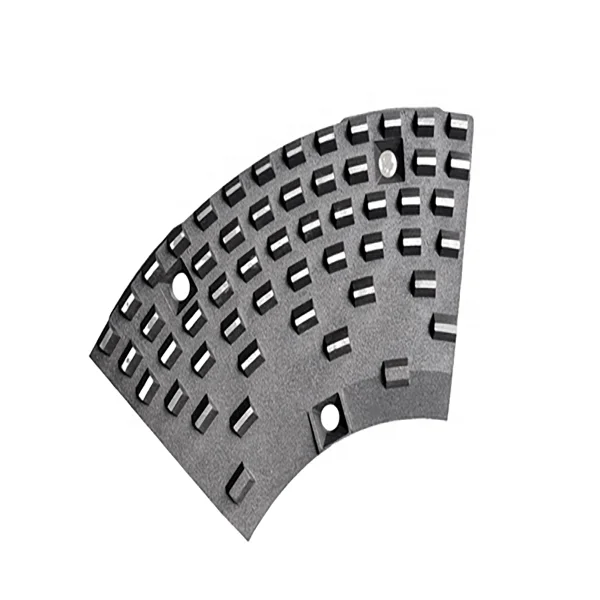

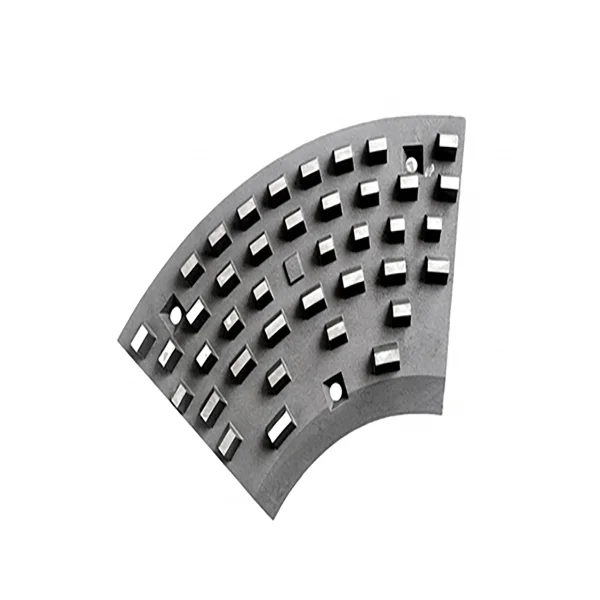

Casting Services Paper Mill Grinding Disc Refiner Segment/Defibrator Machines for MDF and Paper Mill Refining

- Overview

- Recommended Products

Our specialized casting services deliver high-performance grinding disc refiner segments and defibrator machine components for the pulp, paper, and Medium-Density Fiberboard (MDF) industries. These critical wear parts are engineered to withstand extreme abrasive conditions while maintaining precise refining performance in continuous operation.

Advanced Material Technology

We utilize premium wear-resistant alloys specifically formulated for refining applications:

High-chromium cast iron (Cr15-Cr27)

Tungsten carbide reinforced composites

Nickel-chrome hard-facing alloys

These materials undergo specialized heat treatment processes to achieve optimal hardness levels (58-65 HRC) while maintaining necessary toughness to prevent catastrophic failure.

Precision Manufacturing Process

Our production methodology ensures consistent quality:

CAD/CAM pattern design for accurate bar and groove geometry

Shell molding and resin sand casting techniques

Controlled melting in medium-frequency induction furnaces

Precision heat treatment (quenching and tempering cycles)

CNC machining for final dimensional accuracy

Rigorous quality control including hardness testing and dimensional verification

Performance Characteristics

Our cast refiner segments deliver:

Exceptional wear resistance against abrasive wood fibers

Consistent refining performance throughout service life

High impact resistance for tramp metal protection

Corrosion resistance against pulp chemicals

Maintained cutting edge sharpness for optimal fiber treatment

Industry Applications

Our components serve critical functions in:

Paper mill refiners for mechanical and chemical pulping

MDF defibrator machines for fiber separation

Fiberboard production lines

Pulp preparation systems

Recycled fiber processing equipment

Quality Assurance

Every component undergoes comprehensive testing:

Chemical composition analysis

Hardness mapping across working surfaces

Dimensional inspection using CMM

Microstructure examination

Performance validation in test facilities

With our technical expertise in wear-resistant casting technology, we provide refiner segments that deliver extended service life, reduced downtime, and consistent refining performance for MDF and paper production facilities worldwide.

Product descriptions from the supplier

Product name: |

Grind segment |

Specification: |

14-16",17-18",20-24",26-30",42-48",52-58",CC450 |

Material: |

Nickel hard alloy Steel |

Usage: |

Inox Stainless Steel Metal |

Color: |

Natural |

Shape: |

Customized Shape |

Feature: |

Durable |

MOQ: |

1 Piece |

Warranty |

3 years |

ANDRITZ, a key player in the MDF and pulp and paper industry, manufacture it’s famous pressurized refining systems. The ANDRITZ single-disc refiners, equipped with the signature swing door design, enhance efficiency for plate changing process. Their comprehensive solution covers everything from debarking and chipping to screening, washing, and refining.

Q1. What is the advantage about your company? |

||||||||

A1. Our company has professional team and professional production line. |

||||||||

Q2. Why should I choose your products? |

||||||||

A2. Our products are high quality and low price. |

||||||||

Q3. The logo and the color can be customized? |

||||||||

A3. Yes, we welcome you to sample custom. |

||||||||

Q4. Any other good service your company can provide? |

||||||||

A4. Yes,we can provide good after-sale and fast delivery. |

||||||||