- Overview

- Recommended Products

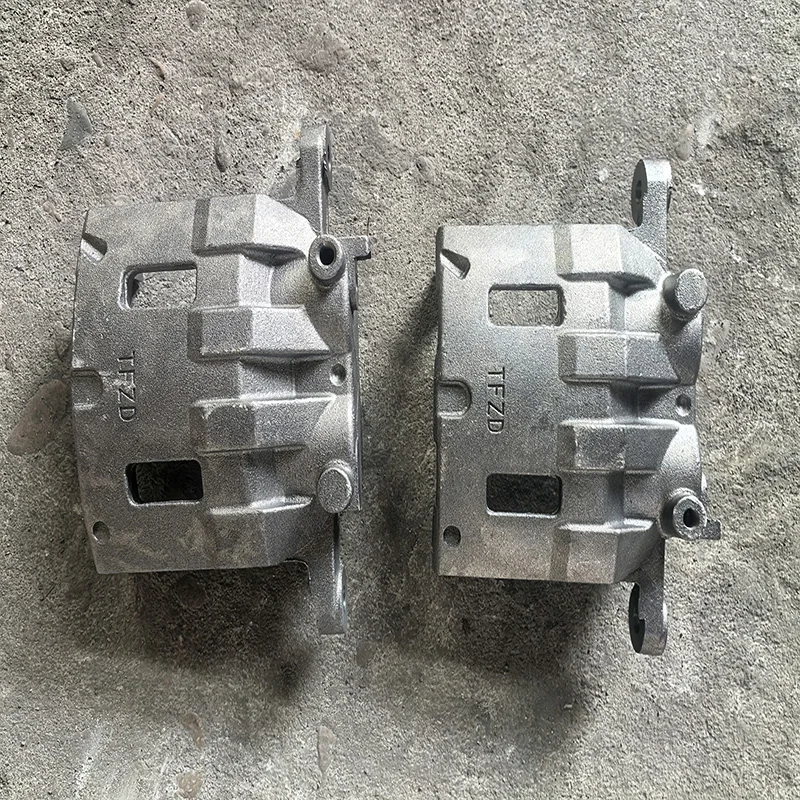

In industrial flow control systems where reliability and durability are non-negotiable, Cast Iron Sand Casting Gate Valves represent the cornerstone of fluid management. Our Premium Quality Casting Services deliver valves that combine robust construction with precision engineering, ensuring long-term performance in the most challenging operating environments.

Superior Material Selection

We utilize high-grade cast iron materials specifically engineered for valve applications:

Gray Iron (GG25): Delivering excellent vibration damping and wear resistance

Ductile Iron (GGG40/50): Providing enhanced tensile strength and impact toughness

Special Alloyed Irons: For specific corrosion resistance and temperature requirements

These materials ensure optimal pressure containment and mechanical stability throughout the valve's service life.

Advanced Manufacturing Process

Our integrated production approach combines traditional foundry expertise with modern quality control:

-

Precision Sand Casting

Resin sand molding technology ensuring dimensional accuracy

Controlled pouring temperatures and solidification rates

Advanced gating systems minimizing turbulence and inclusions

-

Machining & Assembly

CNC machining of sealing surfaces and flange connections

Precision thread cutting for stem and bonnet assemblies

Automated testing of all moving components

-

Surface Treatment

Epoxy coating for corrosion protection

Internal sealing surface enhancement

Performance testing under simulated operating conditions

Key Performance Characteristics

Pressure Rating: PN10-PN25 standards compliance

Temperature Range: -20°C to 350°C operational capability

Pressure Tightness: Zero leakage at 1.1x rated pressure

Cycle Life: Minimum 10,000 full cycles without performance degradation

Flow Characteristics: Low pressure drop design for energy efficiency

Quality Assurance Protocol

Material certification to international standards

Dimensional verification using CMM technology

Hydrostatic testing at 1.5x rated pressure

Non-destructive testing including magnetic particle inspection

Performance validation according to API, ANSI, and DIN standards

Industrial Applications

Our cast iron gate valves serve critical functions across multiple sectors:

Water Treatment Plants: Main isolation and control valves

Chemical Processing: Corrosion-resistant fluid handling

Power Generation: Cooling water and auxiliary systems

Marine Applications: Sea water and ballast systems

Industrial Plumbing: Main supply lines and distribution networks

Through our Premium Quality Casting Services, we deliver gate valves that exceed industry standards for performance and reliability. Our technical support team provides comprehensive application engineering to ensure optimal valve selection and integration, backed by full traceability and documentation for every component.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |