- Overview

- Recommended Products

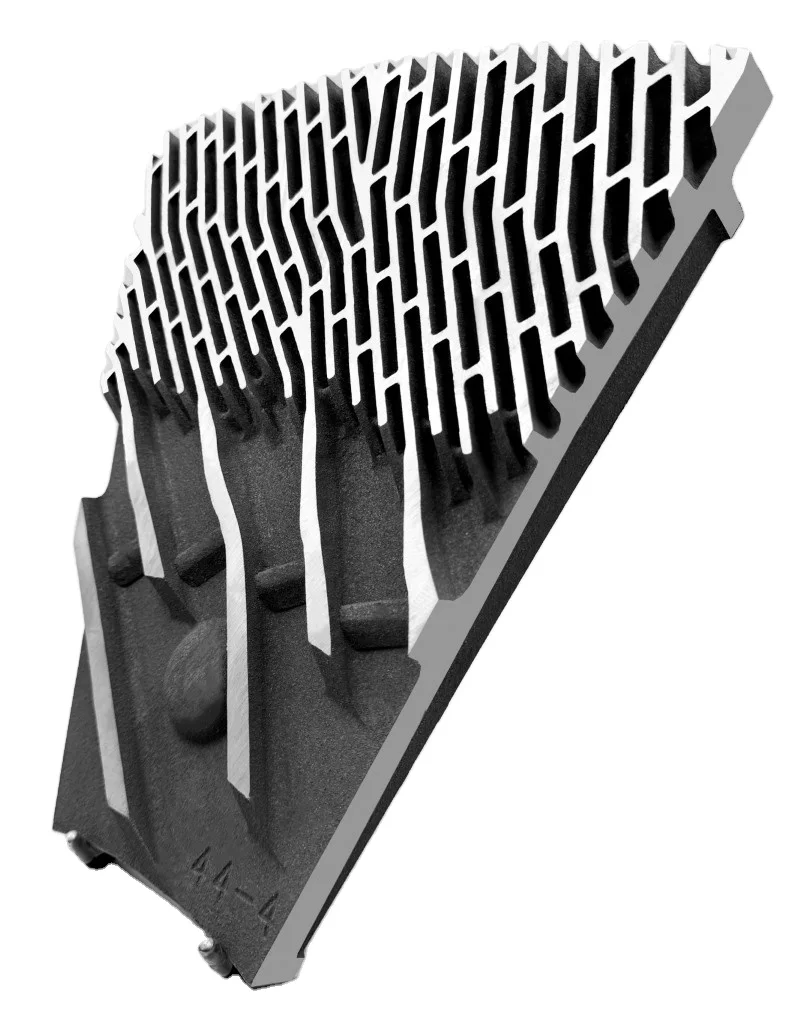

In high-volume Medium-Density Fiberboard (MDF) production, the 58-inch refiner plate represents a critical wear component that directly determines fiber quality, production efficiency, and operational costs. Our specialized casting service manufactures large-diameter alloy refiner discs engineered to withstand the extreme abrasive conditions of MDF fiber preparation, delivering superior wear life and consistent refining performance for continuous panel production operations.

Advanced Wear-Resistant Alloys

We utilize premium materials specifically developed for wood fiber processing applications:

High-Chromium White Iron (HCWI): ASTM A532 Class III Type A composition with 25-28% chromium content, delivering exceptional hardness (62-65 HRC) and microstructural stability

Enhanced Nickel-Chromium White Iron: Ni-Hard formulations optimized for specific wood species and refining conditions

Special Alloy Steel Castings: Custom compositions balancing high surface hardness with core toughness for impact resistance

Tungsten Carbide Enhanced Options: Surface-treated variants for extreme wear applications with contaminated raw materials

All materials undergo comprehensive metallurgical verification including spectral analysis, hardness testing, and microstructural examination to ensure consistent performance across production batches.

Precision Manufacturing Process

Our integrated production system ensures dimensional accuracy and mechanical reliability:

-

Pattern & Mold Engineering

CNC-machined pattern equipment for precise profile reproduction

Advanced resin sand molding technology for large-diameter castings

Optimized gating and feeding systems for sound casting structure

-

Controlled Thermal Processing

Customized austenitizing and quenching cycles for maximum hardness development

Multiple-stage tempering treatments for optimal toughness-to-hardness ratio

Stress relieving processes for dimensional stability

-

Precision Machining & Finishing

CNC machining of mounting surfaces, bolt patterns, and drive features

Accurate profile maintenance of grinding patterns and bar dimensions

Dynamic balancing to G6.3 standards for vibration-free operation

Surface finishing for optimal fiber flow characteristics

-

Quality Assurance Protocol

Full-dimensional verification using laser scanning and CMM technology

Non-destructive examination (PT/UT) for internal and surface quality

Hardness mapping across working surfaces to ensure uniform wear resistance

Microstructural analysis for carbide distribution and matrix integrity

Performance Advantages

Extended Service Life: Superior wear resistance provides 25-40% longer operational periods between plate changes

Consistent Fiber Quality: Precisely maintained pattern geometry ensures uniform fiber dimension and quality

Energy Efficiency: Optimized pattern design reduces specific energy consumption during refining

Reduced Maintenance Costs: Fewer plate changes decrease labor requirements and production losses

Enhanced Operational Stability: Perfect dynamic balance prevents vibration and bearing damage

Technical Specifications

Compatible with major MDF panel machine refiner systems

Available in standard and custom pattern configurations

Meeting or exceeding OEM dimensional tolerances

Complete material certification and traceability documentation

Our technical support team provides comprehensive application assistance including pattern selection, operational parameter optimization, and wear analysis services. We maintain strategic inventory levels for critical sizes to ensure prompt delivery and minimize production downtime. Contact our engineering specialists today for detailed product specifications and discover how our 58-inch refiner plates can enhance your MDF production efficiency, product quality, and operational profitability.

Product name: |

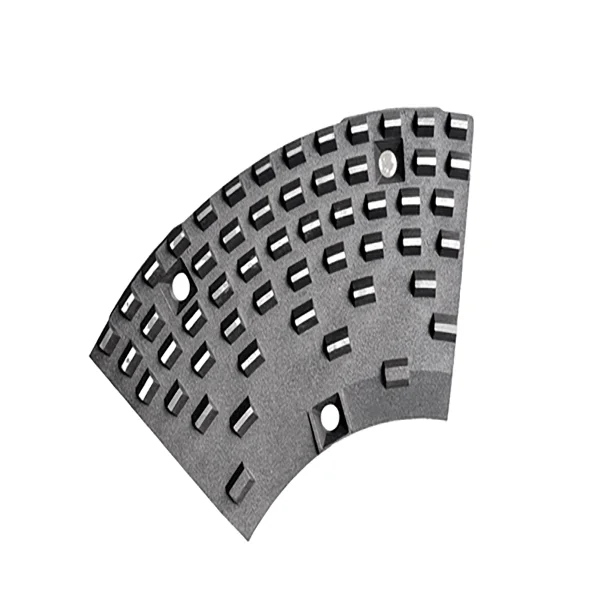

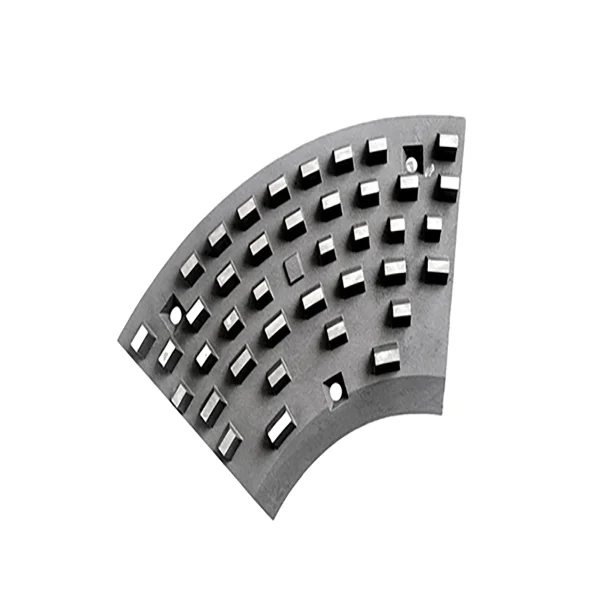

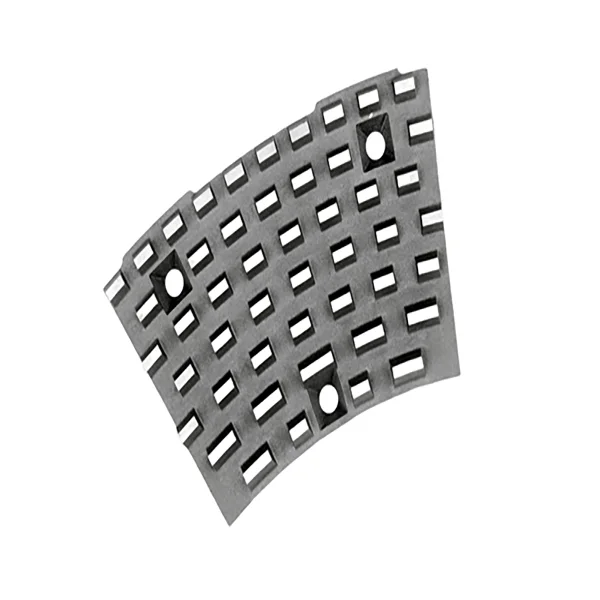

Grind segment |

Specification: |

14-16",17-18",20-24",26-30",42-48",52-58",CC450 |

Material: |

Nickel hard alloy Steel |

Usage: |

Inox Stainless Steel Metal |

Color: |

Natural |

Shape: |

Customized Shape |

Feature: |

Durable |

MOQ: |

1 Piece |

Warranty |

3 years |

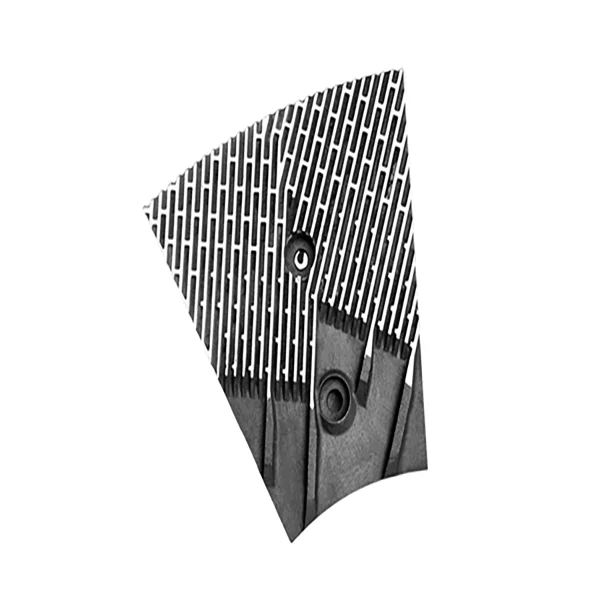

ANDRITZ, a key player in the MDF and pulp and paper industry, manufacture it’s famous pressurized refining systems. The ANDRITZ single-disc refiners, equipped with the signature swing door design, enhance efficiency for plate changing process. Their comprehensive solution covers everything from debarking and chipping to screening, washing, and refining.

Q1. What is the advantage about your company? |

||||||||

A1. Our company has professional team and professional production line. |

||||||||

Q2. Why should I choose your products? |

||||||||

A2. Our products are high quality and low price. |

||||||||

Q3. The logo and the color can be customized? |

||||||||

A3. Yes, we welcome you to sample custom. |

||||||||

Q4. Any other good service your company can provide? |

||||||||

A4. Yes,we can provide good after-sale and fast delivery. |

||||||||