- סקירה

- מוצרים מומלצים

לבעלי משאיות כבדות ולמנהלי צי, אמינות של מנוע קאמינס היא בעלת חשיבות עליונה, והדיסקית (פליג'וויל) היא קישור קריטי במעבר הכוח לtranzimah. American Truck Flywheel, שמסומנת במספר חלקים של יצרן המקור (OEM) 3974147, פותחה כתחליף ישיר לשחזור ושימור הביצועים והעמידות הצפויים מרכבים ממונעי קאמינס. רכיב זה מבטיח העברה חלקה של כוח, הפעלה מהימנה ועמידות לאורך זמן בתנאים הקיצוניים ביותר של הובלה.

חומר איכותי לעמידות חסרת תחרות

גלגל המנוע הזה הוא מיושב מדויק מברזל קמדי עוצמה גבוהה (ברזל דוקטיל), חומר שנבחר עבור תכונות מכניות עולות על ברזל אפור רגיל. ברזל קמדי מציע איזון יוצא דופן של עוצמת נמשכה גבוהה, עמידות ללבוש מצוינת, ועוצמת מכה יוצאת דופן. זה חיוני כדי לעמוד בקומנט גבוה של מנועי דיזל של Cummins ובמחזורי ההתקשרות המתמשכים של מנועי סטארטר כבדים ומערכות המקבץ. עמידותו המובנית של החומר לעיוות ועייפות תרמית מבטיחה ביצועים עקביים ומונעת בעיות כמו צעקות מצמד ונקודות חמות, אפילו תחת טמפרטורות עבודה קיצוניות.

הנדסה והפקה מדויקות

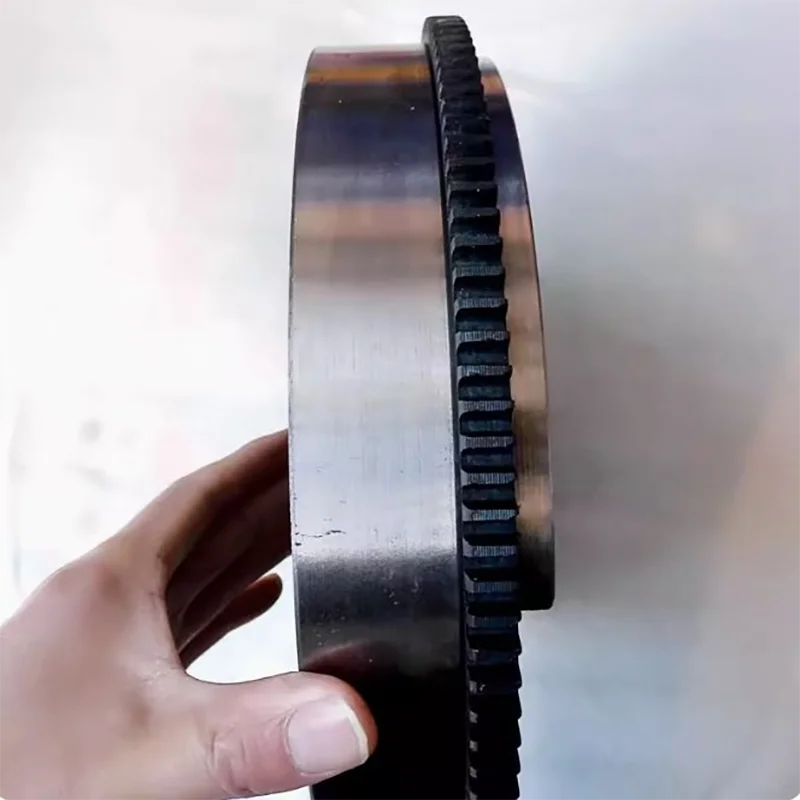

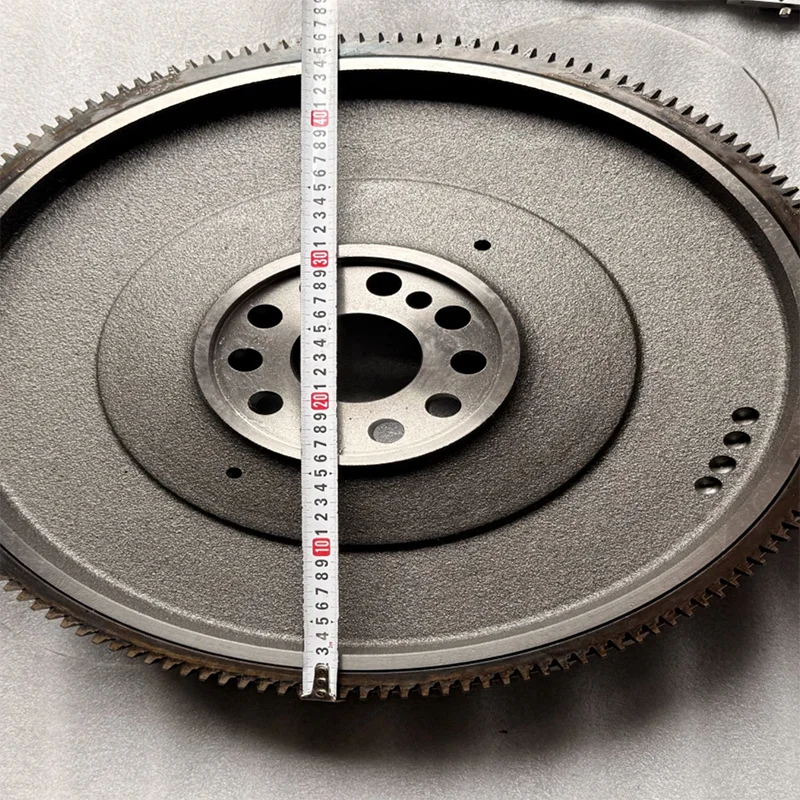

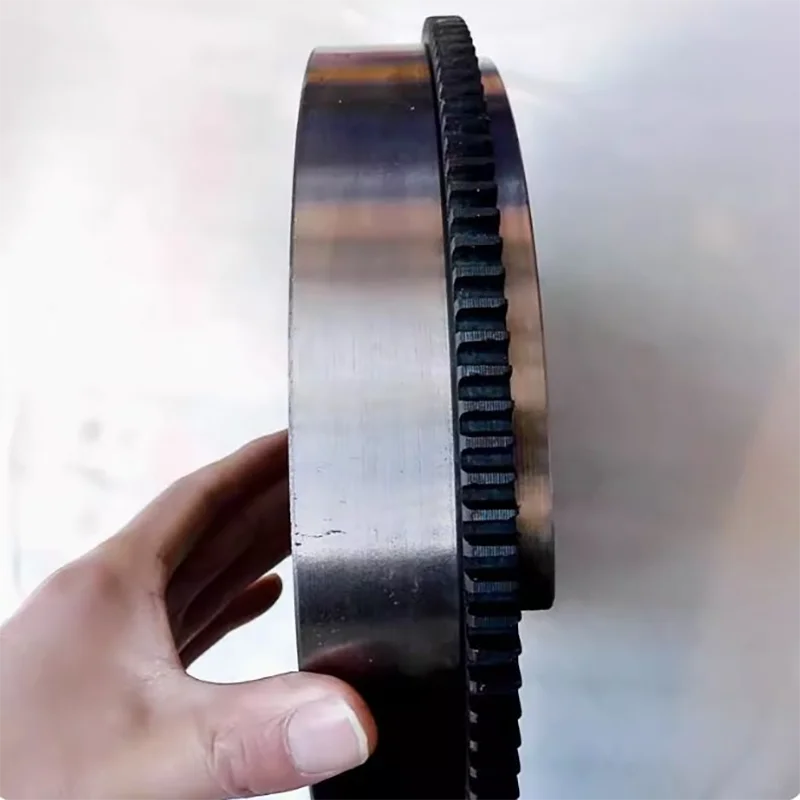

תהליך הייצור מתחיל עם יציקה מבוקרת כדי ליצור בסיס צפוף וחופשי מפגמים. לאחר מכן עובר גל האיזון עיבוד CNC מקיף כדי להשיג את המפרט הקריטי של ה-OEM. זה כולל סיבוב מדויק של משטח החיכוך כדי להבטיח שטיחות מושלמת, חקיקה של פתח הציר הראשי לצורך יישור מדויק, ועיבוד של דף ההרכבה כדי להתאמה אמינה. טבעת השן של גלגל ההפעלה עובדת טיפול حراري כדי להשיג קשיחות ועמידות מרביים, ואז מותקנת בדיוק כדי להבטיח התאמה מושלמת. לבסוף, כל גל איזון מאוזן דינמית לתקן גבוה, מה שמבטל רעידות שיכולות לפגוע במיסב הציר הראשי וברכיבים אחרים של מערכת ההנעה, ובכך מבטיח פעילות מנוע חלקה וחיים ארוכים של מערכת הכוח.

יישום ישיר לביצועים אמינים

מספר חלק הצמיג 3974147 מעוצב כרכיב מתאים ישירות למודלי מנוע ספציפיים של קאמינס, הנמצאים במגוון רחב של משאיות אמריקאיות. זהו חלק חשוב בהרכבת המצמד, והוא מספק את משטח החיכוך לדיסק המצמד ומאפשר את החיבור בין המנוע לתיבת הילוכים. צמיג זה הוא הפתרון המדויק לצורך תיקונים הנדרשים всרֵג wear, נזק חום או סדקים במשטח של החלק המקורי. פעולתו הנ dependable היא חיונית להחלפות הילוכים חלקות, העברת כוח יעילה ולמניעת נזקי תמסורת יקרים, מה שהופך אותו לרכיב חיוני לצורך שימור זמני עבודה ויעילות של הצי.

בחרו בצמיג זה באיכות גבוהה למשאיות אמריקאיות כדי להבטיח שהמנוע קאמינס שלכם י brja את הביצועים עמידים ואמין שעליהם תלויה העסק שלכם.

עלינו

מדוע אנו מכונים מומחי OEM במניפולדים? |

אנו מפתחים מעל 100 סוגים שונים של אסימונים בכל שנה |

||||||

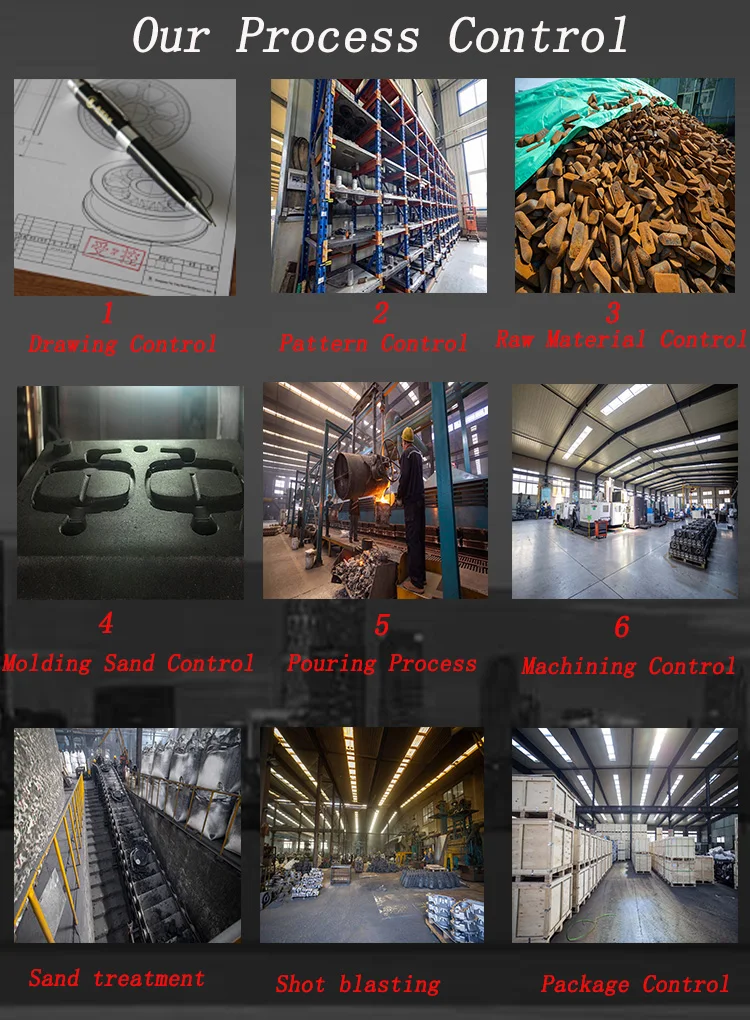

תהליך הייצור של דנדונג פנגשין לאסימונים |

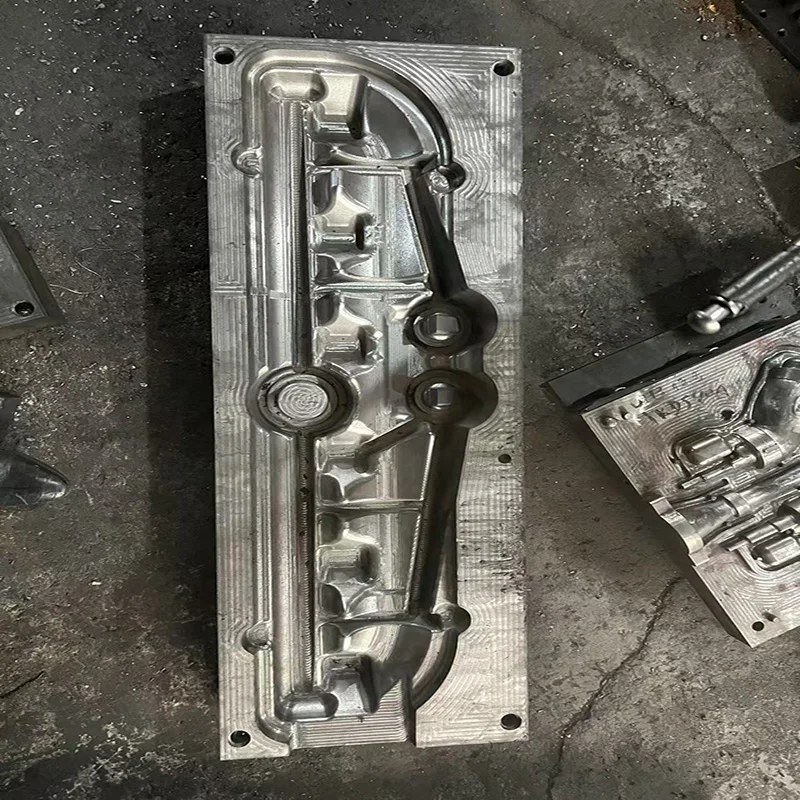

הכנה של שרטוט: היסוד של דיוק, סריקת 3D ושרטוט: מהנדסים מקצועיים שלנו משתמשים בסורקים מתקדמים להמרת דוגמאות לשרטוטים דו-ממדיים/תלת-ממדיים (7–10 ימים). |

||||||

פיתוח תבניות ודוגמאות: שם השקעת הזמן משתלמת |

מורכבות: לעתים קרובות נדרשים למאגרי פליטה 3–5 סטים של תבניות מתכת ( לעומת סט אחד לתבניות פשוטות יותר ). זמן מוביל: 35–40 ימים לתבניות מרובות חריצים; 25–30 ימים לעיצובים פשוטים יותר. |

||||||

הזמנות ראשוניות וylie batches: הגדלה באחריות |

Allocaion מכונה: הזמנת מניפול אחד עלולה לכבס 2–3 מכונות יציקה. המתקן שלנו עם 16 מכונות מסדר את ההזמנות דחופות ועוסק בשיתוף עם יציקות שותפות לבניית ליבות עזר. |

||||||

איך משקיעים יכולים להפחית את התעכומים |

הק allocating 8–12 שבועות לפיתוח דגם/דגימה. הקפצה על תהליך זה עלולה לגרום לכשלים באיכות. האצווה הראשונה לוקחת 20–30% יותר זמן בשל סדרת עדכוני תהליך. לאחר האישור, זמני המובילות מתייצבים. |

||||||

מכירה מוקדמת

בִּמְכִירָה

לאחר מכירה

תוצאות → אנו מזמינים אתכם ליצור קשר כדי לקבל פתרון מותאם אישית.

איך הפכה פנגשין דנדונג לייצרנית מובילה של אסימבי מפלט

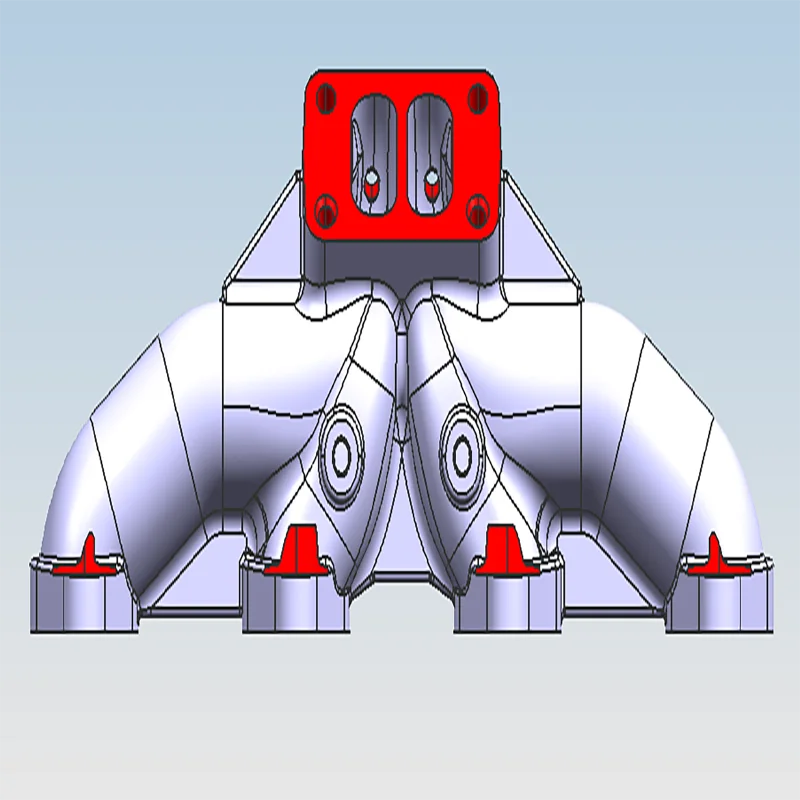

עיצובים תהלוכיים נגזרים משרטוטים הנדסיים

סקנרים תלת-ממדיים

תבנית מתכת למנהרת פליטה, יציקת חול מוכתם

תבנית מתכת לאוסף עישן, יציקה בחול

תבנית פליז עירור

מכונה ליצירת מolds

יציקת חול מוכתם

מachines לציפוי

R&D

קיבולת ייצור

בקרת דפוס

abaqus, Moldflow ו-Moldex 3D, מסמלצים מערכת הזנה, מפחיתים פגמים בזריקה ומשפרים יעילות.

בקרת חומרי גלם

Machining Control