- Yleiskatsaus

- Suositellut tuotteet

Mitsubishi Pajero- ja Montero-omistajille, jotka vaativat ehdotonta luotettavuutta, hidaspyörä on voiman siirron perusta. Tämä valurautainen hidaspyörä, joka on yhteensopiva osanumeroihin 2355A006, MR446366 ja 2355A004, on suunniteltu erityisesti robustia 4M41-dieselmoottoria varten sarjamalleihin V60, V70, V80 ja V90. Se tarjoaa tehtaan alkuperäistuotevertaisen suorituskyvyn, varmistaen tarkan kytkimen toiminnan ja kestävän käytön sekä tieliikenteessä että vaativissa maastokäyttöolosuhteissa.

Korkealaatuinen materiaali erinomaiseen suorituskykyyn

Tämä ensiluokkaisesta harmaasta valuraudasta valmistettu vauhtipyörä tarjoaa poikkeuksellisen kestävyyden ja toiminnalliset ominaisuudet, jotka ovat kriittisiä dieselmoottorisovelluksissa. Materiaali tarjoaa suuren vetolujuuden kestämään 4M41-moottorin merkittävän vääntömomentin, ja sen erinomainen lämmönkestävyys estää kytkimen kitkan aiheuttamaa vääntymistä ja lämmönmuodostusta. Lisäksi valuraudan luontaiset tärinänvaimennusominaisuudet edistävät tasaisempaa moottorin toimintaa, vähentävät vaihteiston melua ja parantavat ajomukavuutta, mikä on olennaista ajoneuvolle, joka tunnetaan hienostuneisuudestaan ja kyvykkyydestään.

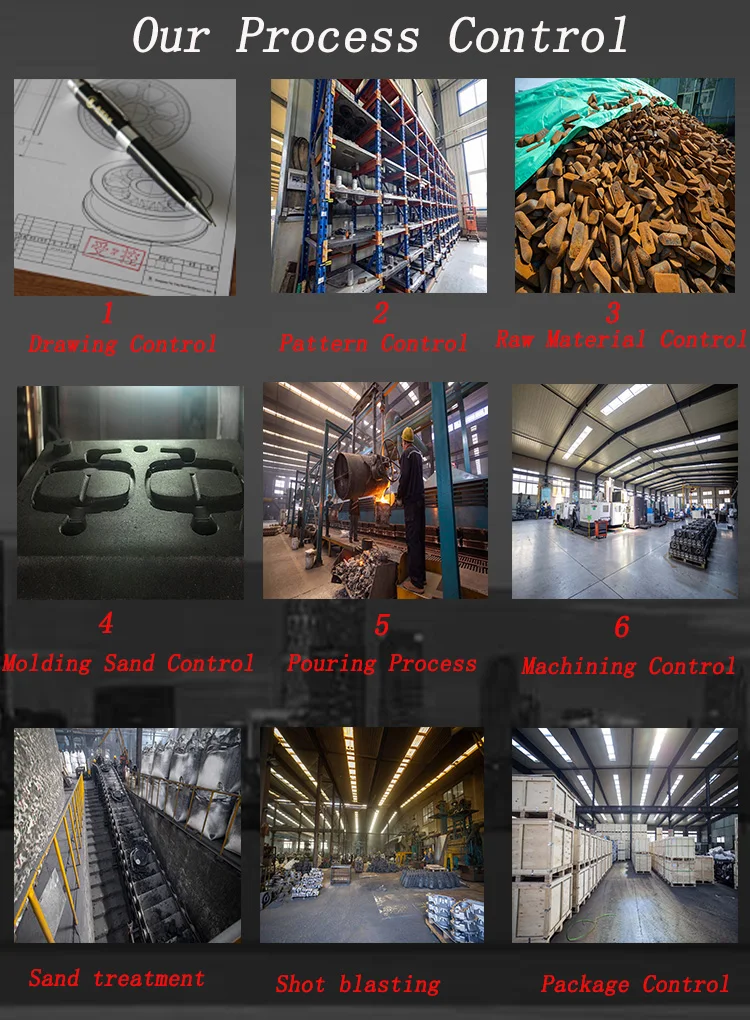

Tarkkuudella ohjattu tuotantoprosessi

Tämän komponentin valmistuksessa käytetään edistyneitä hiekkavalutekniikoita tiheän, homogeenisen rakenteen saavuttamiseksi ilman sisäisiä virheitä. Tähän peruslaatuun liittyy tarkka CNC-konepursinta kaikilla kriittisillä pinnoilla. Toimenpiteisiin kuuluu kitkapinnan sorvaus varmistaakseen täydellisen tasomaisuuden sekä kiinnitysliittimen konepursinta takaamaan täydellinen keskisyys kampiakselin kanssa. Hammaspyörärengas asennetaan huolellisesti takuulla virheettömän käynnistysmoottorin kytkemisen. Lopuksi jokainen ratas tasapainotetaan dynaamisesti, mikä on ratkaisevan tärkeä vaihe värähtelyjen poistamiseksi, sillä ne voivat aiheuttaa ennenaikaista kulumista kampiakseliin ja vaihteiston laakerointeihin.

Suora asennus luotettavuuden turvaamiseksi

Tämä hihnavyö on suora vaihtoehto määritettyihin OEM-osanumeroihin, ja se on suunniteltu täydelliseen sovitukseen 4M41-voimanlähteeseen. Se on olennainen osa kytkentäjärjestelmän perusteellisessa huollossa, ja varmistaa tehokkaan voiman siirron moottorilta vaihdelaatikkoon. Laadukas hihnavyö on ratkaisevan tärkeä estämään kytkimen luistamista, tärinää ja vaikeita vaihteenvaihtoja, palauttaen samalla ajoneuvon alkuperäiset ajo-ominaisuudet ja luotettavuuden. Sen kestävä rakenne tekee siitä ihanteellisen valinnan niille innokkaille ja ammattilaisille, jotka huoltavat näitä legendaarisia Mitsubishi-SUV:ja jatkuvaa seikkailua ja arkipäivän käyttöä varten.

Miksi meitä kutsutaan OEM-asiantuntijaksi pakoputkien saralla |

Kehitämme yli 100 erilaista pakoputkistoa vuosittain |

||||||

Dandong Pengxinin pakoputkiston valmistusprosessi |

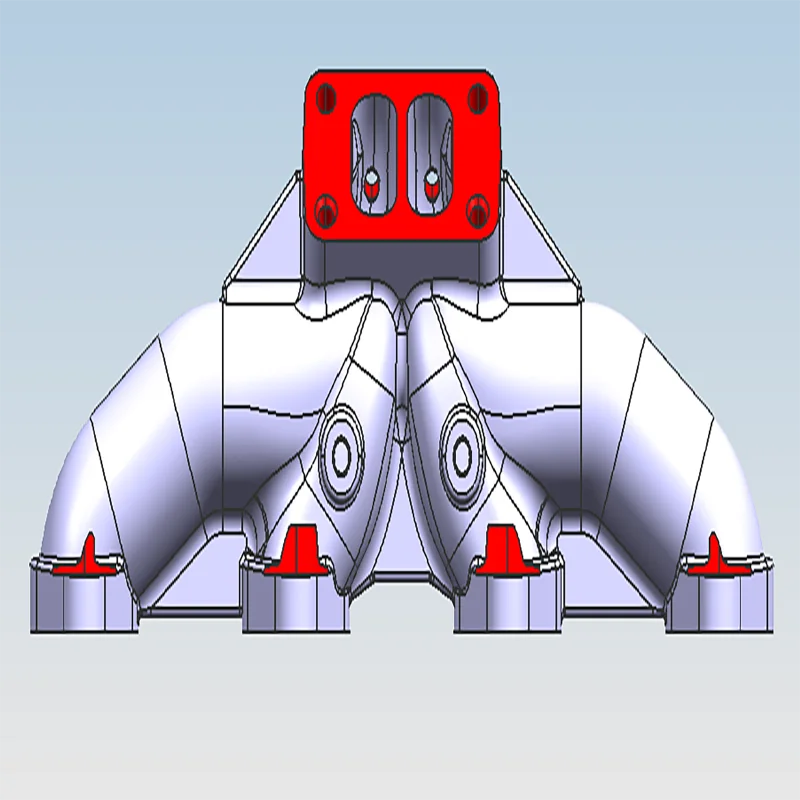

Piirustusten laatiminen: Tarkkuuden perusta, 3D-skannaus ja piirustus: Ammattilaissuunnittelijamme käyttävät edistyneitä skannereita muuntaakseen näytteet 2D/3D-piirustuksiksi (7–10 päivää). |

||||||

Mallin ja näytteen kehittäminen: Missä sijoitetulla ajalla maksetaan takaisin |

Monimutkaisuus: Poistoharjat vaativat usein 3–5 joukkoa metallimuotteja (yksi joukko yksinkertaisemmissa valuteissa). Toimitusaika: 35–40 päivää monikammioisille muoteille; 25–30 päivää yksinkertaisemmille suunnitteluille. |

||||||

Alkuperäiset tilaukset ja sarjatuotanto: Vastuullista skaalautumista |

Koneiden jakaminen: Yksittäinen manifoldivaraus voi varata 2–3 muovaukoneella. Meidän 16-koneisessa laitoksessa kiireellisiin tilauksiin annetaan etusijaa ja yhteistyötä käytetään apuytimiä varten kumppanilevyllä. |

||||||

Mitä sijoittajat voivat tehdä viiveiden vähentämiseksi |

Varaa 8–12 viikkoa mallin/näytteen kehittämiseen. Ajan tiivistäminen saattaa aiheuttaa laatuongelmia. Ensimmäiset erät kestävät 20–30 % kauemmin prosessien hionnan vuoksi. Hyväksynnän jälkeen toimitusaika stabiloituu. |

||||||

Ennakkomyynti

Myynnissä

Asiakaspalvelu

tulokset→Ota yhteyttä meihin saadaksesi räätälöidyn ratkaisun.

Miten Dandong Pengxinista tuli huipputuottaja moottorin sylinteripääputkien saralla

Prosessisuunnitelmat perustuvat konetuotantopiirustuksiin

3D-skannerit

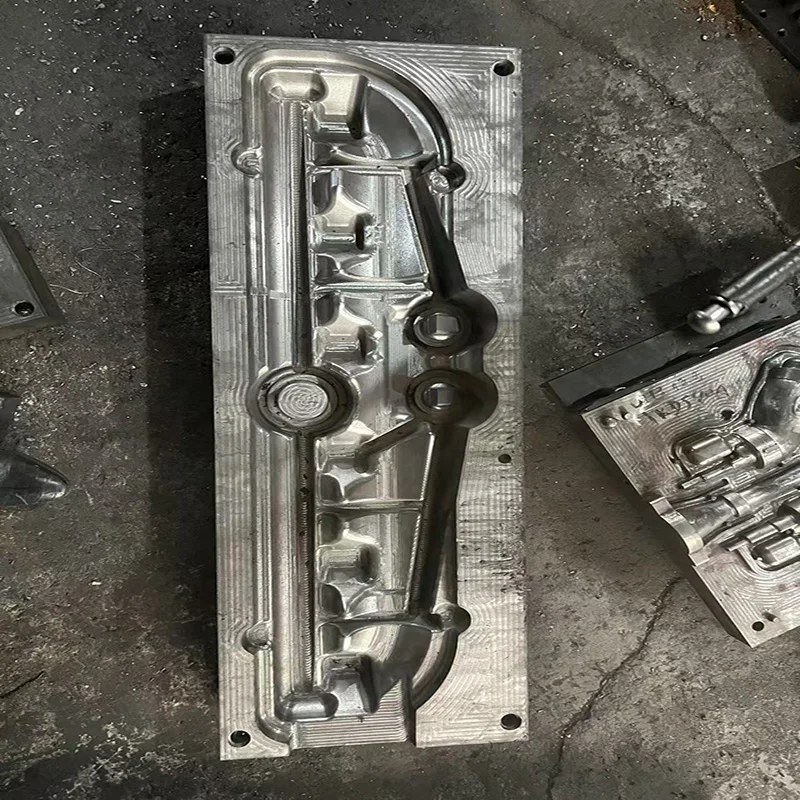

Metallimuotti pakoputkille, Koristetyt hiekkaformit

Metallimuotti pakoputkistolle, hiekkavalu

Pakoputkiston ydinkotelo

Kuorimuotokone

Koristetyt hiekkaformit

Mallintusketjut

Tutkimus & kehitys

Tuotantokapasiteetti

Mallinohjaus

abaqus, Moldflow ja Moldex 3D, simuloidaan ruokintajärjestelmä, vähennetään valuvirheitä ja parannetaan tehokkuutta.

Raaka-aineiden valvonta

Koneistuksen valvonta