- Overview

- Recommended Products

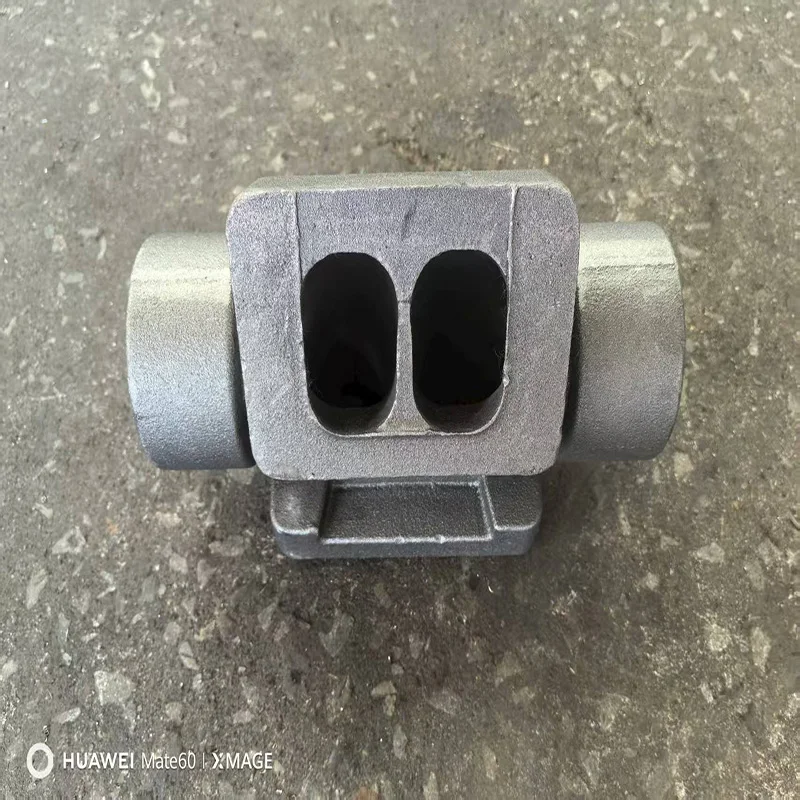

For commercial vehicle operators and repair shops maintaining Ford Transit 2.2L diesel engines, finding reliable exhaust manifold solutions requires understanding both material durability and manufacturing excellence. While this product addresses used component needs, it represents the sophisticated casting technology that ensures long-term performance in demanding delivery and transport applications.

Material Engineering Excellence

The original manifold utilizes high-grade grey cast iron specifically engineered for diesel applications:

Flake graphite structure providing optimal thermal conductivity and vibration damping

Controlled silicon content (1.8-2.4%) enhancing oxidation resistance at sustained 650°C operation

Molybdenum addition (0.3-0.5%) significantly improving thermal fatigue resistance

Precision-controlled carbon equivalent ensuring consistent mechanical properties

Precision Manufacturing Heritage

Original production followed Ford's stringent manufacturing protocols:

High-pressure molded sand casting ensuring dimensional accuracy within ±0.8mm

Computer-controlled machining of flange surfaces maintaining 0.15mm flatness tolerance

Stress relief annealing at 550°C for 4 hours preventing internal casting stresses

Automated surface processing achieving optimal exhaust gas flow characteristics

Performance and Durability Features

The manifold design incorporates Ford's specific engineering requirements:

Optimized runner geometry balancing exhaust pulse separation efficiency

Reinforced turbocharger mounting flange resisting thermal warping

Strategic reinforcement ribbing controlling thermal expansion stresses

Precision-machined surfaces ensuring proper cylinder head sealing integrity

Quality Assessment Protocol

Each used unit undergoes comprehensive revalidation process:

Visual inspection and dye penetrant testing for micro-crack detection

Surface flatness verification using precision straight edge methodology

Thread integrity assessment for all mounting points and stud connections

Critical wall thickness measurement at high-stress concentration areas

Application-Specific Engineering

Designed specifically for Ford Transit applications:

2.2L Duratorq diesel engines (2006-2014 production years)

Multiple chassis configurations including front and rear-wheel drive variants

Various body styles from panel vans to chassis cab installations

High-mileage commercial vehicle operating conditions

Technical Compatibility

Direct replacement for OEM specifications and bolt patterns

Maintains factory emissions system compliance requirements

Full compatibility with standard turbocharger configurations

Suitable for both repair shops and fleet maintenance programs

Sustainable Engineering Value

Choosing quality-inspected used components provides:

Cost-effective maintenance solution without performance compromise

Environmental advantage through responsible parts reuse

Immediate availability for urgent repair requirements

Proven reliability from original equipment manufacturing standards

For Ford Transit operators seeking practical exhaust manifold solutions, these used components deliver proven performance backed by original casting excellence. Our verification process ensures each unit meets operational requirements while providing exceptional value for commercial vehicle maintenance.

Contact our technical team for current inventory and compatibility verification for your specific Transit application. We provide comprehensive support including installation guidance and technical specifications to ensure proper fitment and operational reliability.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |