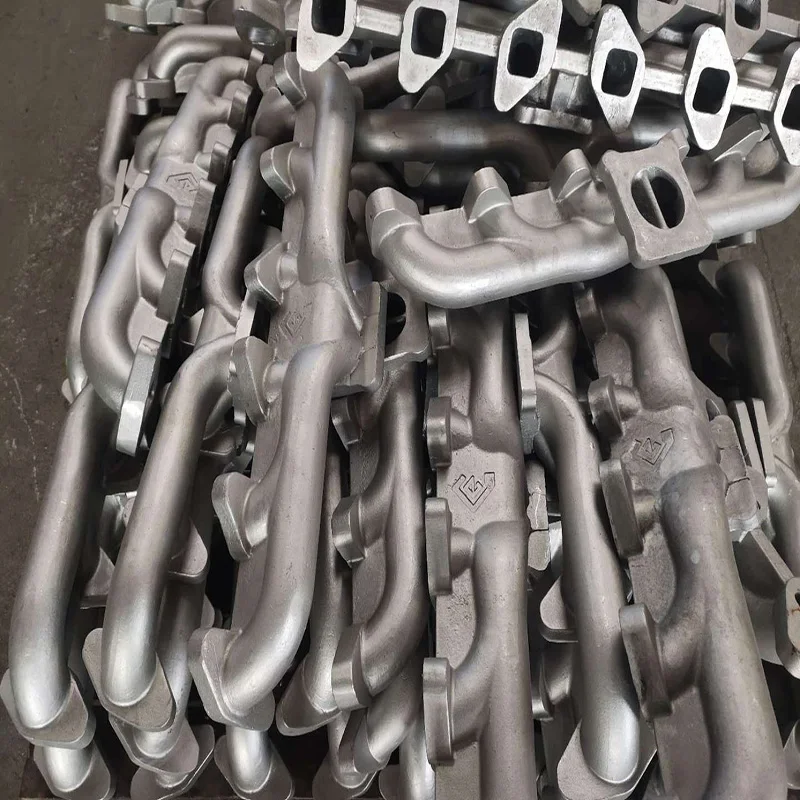

Stainless Steel Investment Casting Turbine Meter Impeller Pump Impeller Premium Quality Casting Services Product

- Overview

- Recommended Products

In the precise world of flow measurement and fluid transfer, the impeller stands as a heart component, dictating efficiency, accuracy, and longevity. Our Premium Quality Casting Services specialize in manufacturing Stainless Steel Investment Casting components, producing high-performance Turbine Meter Impellers and Pump Impellers that meet the stringent demands of critical applications. We deliver parts with exceptional dimensional accuracy, hydraulic efficiency, and corrosion resistance for the most challenging environments.

Advanced Stainless Steel Alloys for Corrosive and High-Strength Applications

We utilize a range of premium corrosion-resistant alloys, selected based on specific media and operational stress:

304/304L Stainless Steel: Provides excellent general corrosion resistance for a wide range of water, chemical, and food processing applications, offering a balance of performance and cost-effectiveness.

316/316L Stainless Steel: Enhanced with molybdenum for superior resistance to chlorides and acidic environments, making it the ideal choice for marine, offshore, and chemical processing duties.

17-4 PH (Precipitation Hardening) Stainless Steel: This grade can be heat-treated to achieve high tensile strength and hardness while maintaining good corrosion resistance. It is essential for high-RPM pump impellers and turbine meter blades requiring exceptional resistance to erosion, cavitation, and mechanical deformation.

Precision Investment Casting for Optimal Hydraulic Performance

The investment casting (lost-wax) process is uniquely suited for producing the complex, thin-walled, and aerodynamically precise geometries of impellers.

Unmatched Geometric Complexity: This process allows for the integration of complex, backward-curved blades, tight tolerances on blade profile, and smooth surface finishes that are critical for minimizing hydraulic losses and maximizing efficiency.

Superior Surface Finish: As-cast surfaces typically achieve 125-250 Ra microinches, reducing flow turbulence and the need for extensive post-casting finishing. This inherent smoothness is crucial for maintaining calibration accuracy in turbine meters and maximizing pump efficiency.

Dimensional Accuracy and Repeatability: The process yields near-net-shape parts with exceptional dimensional stability, ensuring consistent performance and perfect balance in every production batch, run-after-run.

Integrated Value-Added Services

Our service is comprehensive, ensuring components are ready for dynamic balancing and assembly:

Precision CNC Machining: We machine critical interfaces such as the hub bore and keyways to precise tolerances for a perfect fit on the shaft.

Dynamic Balancing: We offer precision balancing services to ISO 1940 G2.5 or better standards, which is critical for high-speed operation to minimize vibration, reduce bearing wear, and prevent premature failure.

Passivation & Electropolishing: These finishing options enhance the natural corrosion resistance of stainless steel, provide a ultra-smooth surface to resist fouling, and facilitate easier cleaning.

Proven Applications in Demanding Industries

Our cast stainless steel impellers are engineered for reliability in:

Flow Metering: Turbine meter impellers for custody transfer and precision measurement in oil & gas, and chemical injection systems.

Chemical & Process Pumps: Handling corrosive, abrasive, and high-purity fluids.

Marine & Offshore: Seawater circulation, ballast, and fire pump systems.

Power Generation: Cooling water and boiler feed pump applications.

Partner with us for impellers that define precision and durability. Our investment casting expertise delivers the hydraulic efficiency, material integrity, and balanced performance that your critical flow control and pumping systems require.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |