- Overview

- Recommended Products

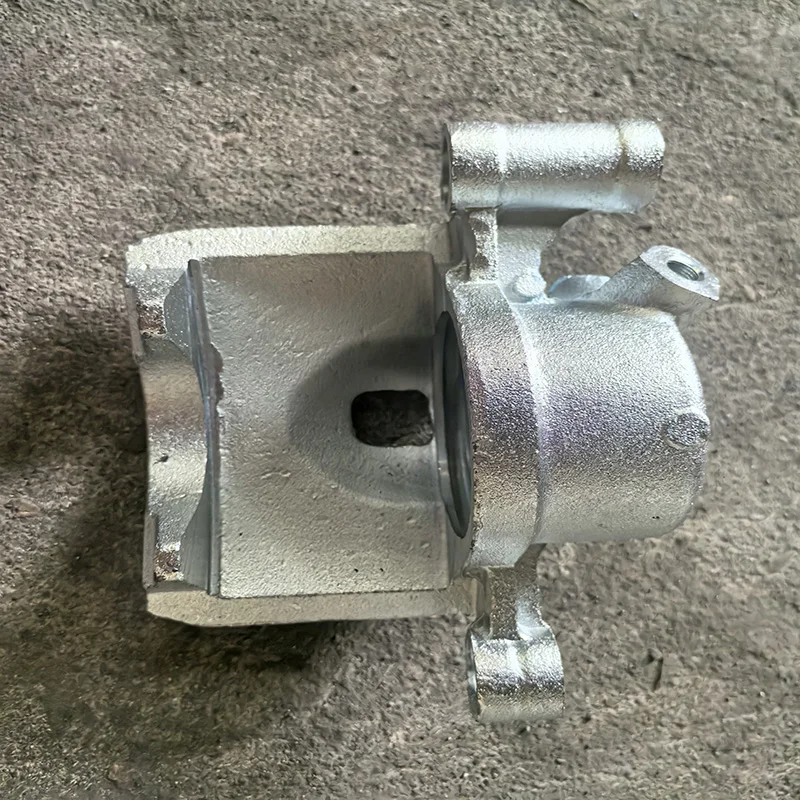

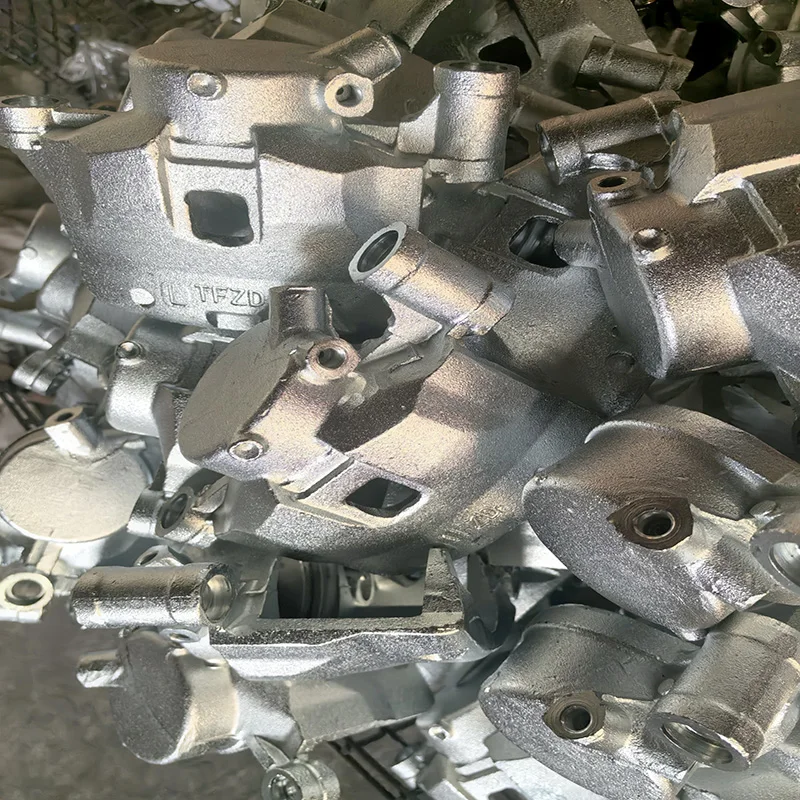

As a leading OEM aluminum casting supplier, we specialize in delivering precision-engineered components through advanced processes like Aluminum Injection Die Casting and Chrome Casting. These services are designed to meet the highest standards of durability, functionality, and aesthetics for industries requiring robust and visually appealing metal parts. This article explores the materials, performance benefits, production techniques, and applications of these specialized casting methods.

Superior Materials and Enhanced Performance

We utilize high-grade aluminum alloys, such as A380, ADC12, and A383, known for their excellent fluidity, lightweight properties, and corrosion resistance. For components requiring enhanced surface properties, our Chrome Casting process involves applying a decorative and protective chrome finish to aluminum parts. This electroplated layer significantly improves surface hardness, wear resistance, and corrosion protection while providing a bright, reflective appearance. The combination of aluminum’s inherent strength-to-weight ratio with chrome’s durability results in parts that withstand harsh environments, heavy use, and exposure to chemicals or moisture without compromising on aesthetics.

Advanced Production Workflow

Our Aluminum Injection Die Casting process begins with melting the aluminum alloy, which is injected at high pressure into precision-engineered steel molds. This ensures the replication of complex geometries with tight tolerances and minimal post-processing. The process is optimized for high-volume production, consistency, and minimal material waste. For Chrome Casting, die-cast components undergo meticulous surface preparation, including polishing, cleaning, and electroplating. The chrome layer is applied through a multi-stage plating process, ensuring uniform coverage and adhesion. Advanced quality checks, such as thickness testing and corrosion resistance validation, guarantee the finished parts meet industry standards for both performance and appearance.

Diverse Industrial Applications

The versatility of our services makes them ideal for a wide range of applications across multiple sectors:

Automotive: Grilles, trim components, door handles, and engine brackets.

Consumer Electronics: Housings for laptops, decorative bezels, and heat sinks.

Industrial Machinery: Wear-resistant parts, hydraulic components, and decorative fittings.

Home Appliances: Handles, knobs, and premium fixtures for kitchen and bathroom equipment.

By integrating Aluminum Injection Die Casting with Chrome Casting capabilities, we provide end-to-end solutions for OEMs seeking components that excel in mechanical performance, dimensional accuracy, and visual appeal. Our expertise ensures reliable, high-quality parts tailored to the unique demands of each project.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |