- Overview

- Recommended Products

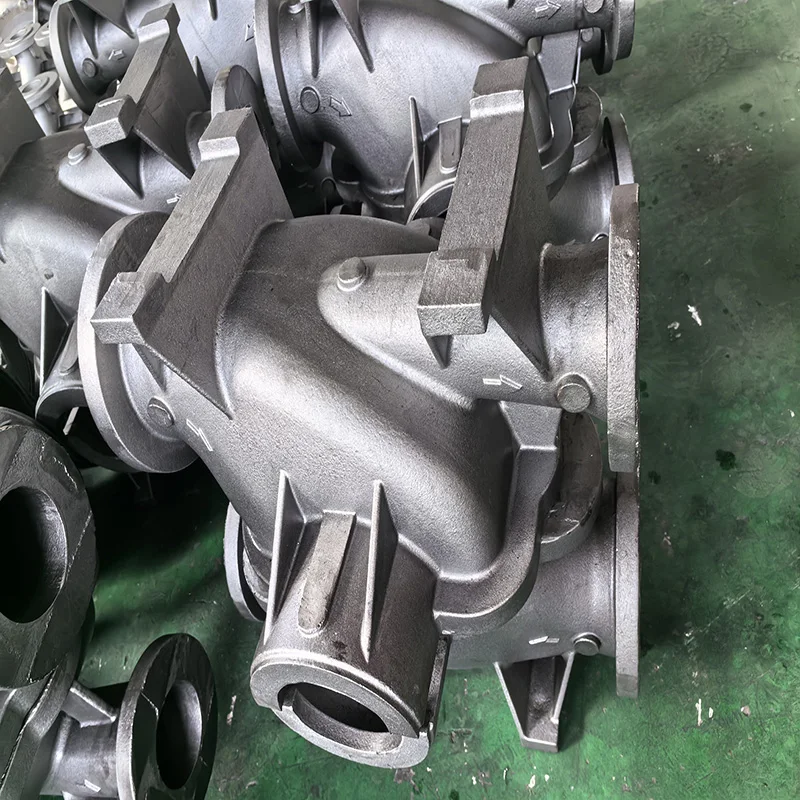

In an industry where quality and reliability are paramount, our ISO 9001 certified fabrication services stand as a testament to our commitment to excellence. We specialize in producing high-performance OEM ductile SG iron castings that meet the most demanding specifications across various sectors. Our certified quality management system ensures every component delivers consistent performance, dimensional accuracy, and long-term durability, making us the preferred partner for global clients seeking uncompromising quality in their casting solutions.

Material Excellence: Ductile SG Iron Properties

Ductile Spheroidal Graphite (SG) iron represents the pinnacle of cast iron technology, offering exceptional mechanical properties:

Superior Strength & Toughness: Tensile strength ranging from 400 MPa to 900 MPa across different grades, with excellent impact resistance

Enhanced Ductility: Typical elongation of 10-18% provides remarkable resistance to shock loading

Excellent Wear Resistance: Ideal for components subjected to friction and abrasive conditions

Good Machinability: Despite its high strength, maintains favorable machining characteristics

Outstanding Fatigue Resistance: Withstands cyclic loading conditions without failure

Certified Manufacturing Process

Our ISO 9001 certified process ensures unmatched quality control:

-

Advanced Foundry Technology:

Computer-controlled melting and alloying systems

Ceramic slurry molding for superior surface finish

Controlled magnesium treatment for perfect nodularity

-

Quality Assurance Protocols:

Spectroscopic analysis for precise chemical composition

Microstructure examination ensuring >85% nodularity

Mechanical testing for every production batch

Non-destructive testing including ultrasonic and radiographic inspection

-

Precision Machining:

CNC machining centers maintaining tolerances within ±0.02mm

Customized finishing per OEM specifications

Comprehensive measurement reports with CMM verification

Performance Advantages

Consistent Quality: Batch-to-batch consistency guaranteed by ISO 9001 systems

Design Flexibility: Complex geometries with wall thickness from 5mm to 150mm

Cost Efficiency: Reduced machining time and material waste

Long Service Life: Superior mechanical properties ensure extended component lifespan

Applications

Automotive Components: Crankshafts, differential carriers, brake components

Industrial Machinery: Heavy-duty gears, hydraulic valve bodies, press frames

Construction Equipment: Excavator components, crane parts, structural elements

Power Generation: Wind turbine hubs, generator components

Agricultural Machinery: Transmission cases, implement components

Partner with our certified fabrication services for ductile SG iron castings that combine quality assurance with engineering excellence. Contact us today to discuss your OEM requirements and benefit from our ISO 9001 certified manufacturing processes.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |