- Overview

- Recommended Products

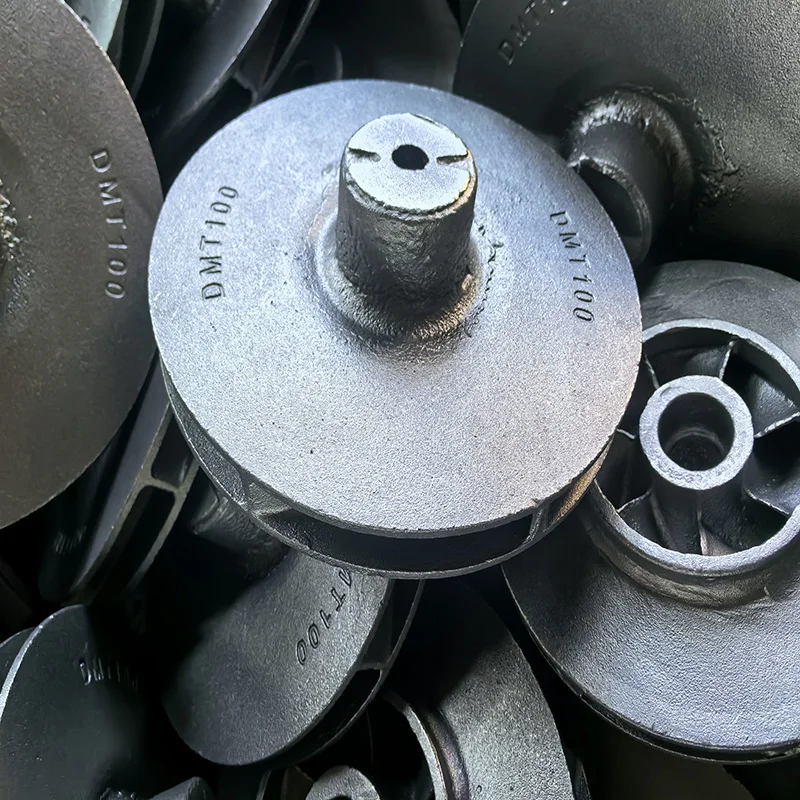

In today's demanding industrial environment, the reliability and performance of machinery depend heavily on the quality of spare components. Our Industrial CNC Machining Spare Parts, supported by Premium Casting Services, represent the pinnacle of manufacturing excellence, delivering unmatched durability, precision, and longevity for critical applications across diverse sectors.

Advanced Materials for Superior Performance

We utilize high-grade materials engineered for specific operational demands. Our expertise spans:

Cast Iron (Gray Iron/Ductile Iron): Delivering exceptional damping capacity, wear resistance, and compressive strength for high-vibration environments

Aluminum Alloys (ADC12/A356): Providing an optimal strength-to-weight ratio with excellent corrosion resistance and thermal conductivity

Stainless Steel (304/316): Offering superior corrosion resistance and mechanical strength for harsh operating conditions

Specialty Alloys: Including bronze and brass for specific friction and conductivity requirements

Integrated Manufacturing Process

Our two-stage manufacturing approach ensures complete quality control from raw material to finished product:

Premium Casting Services

We employ advanced casting techniques (sand casting, die casting, and investment casting) to create near-net-shape components with:

Complex internal geometries and optimized wall thickness

Superior surface integrity and minimal material defects

Consistent metallurgical properties throughout each casting

Precision CNC Machining

Our state-of-the-art CNC centers transform cast blanks into finished spare parts with:

Tight tolerances within ±0.01mm for perfect fit and function

Optimized surface finishes for enhanced sealing and reduced friction

Perfect bore alignment and mounting surface flatness

Critical Industrial Applications

Our precision spare parts serve vital functions in:

Heavy Machinery: Replacement gears, bearing housings, and hydraulic components

Manufacturing Equipment: Precision guides, spindle housings, and feed mechanisms

Process Industries: Pump casings, valve bodies, and compressor parts

Transportation: Engine components, transmission parts, and braking system elements

By combining premium casting expertise with precision CNC machining, we deliver spare parts that not only match but often exceed OEM specifications. This integrated approach ensures reduced downtime, extended equipment life, and optimal performance for your most critical operations.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |