- Overview

- Recommended Products

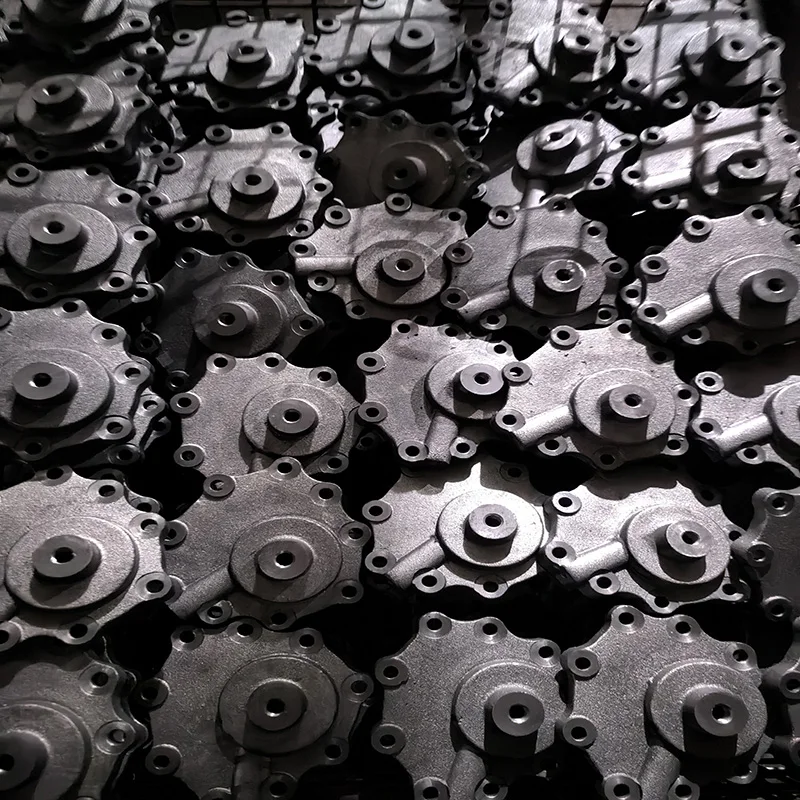

As a global manufacturing hub, China offers Hot Selling Iron Steel Sand Casting Services that combine cost-effectiveness with exceptional quality. Our comprehensive service covers everything from initial Design consultation and engineering to Factory Mold fabrication and high-volume production. We specialize in creating durable, high-performance cast components for global clients across diverse industries, delivering the perfect balance of mechanical properties, dimensional accuracy, and competitive pricing.

Advanced Ferrous Alloys for Diverse Applications

Our foundry utilizes a full spectrum of ferrous materials to meet specific operational requirements:

Gray Iron (GJL) Grades 150-350: Delivering excellent vibration damping and machinability for base plates and engine components

Ductile Iron (GGG) Grades 400-600: Providing superior tensile strength and impact resistance for gears and structural parts

Carbon Steel (GS) Grades 200-500: Offering exceptional weldability and impact toughness for heavy machinery components

Low-Alloy Steel Grades: Featuring enhanced mechanical properties through chromium, nickel, and molybdenum additions

Precision-Controlled Sand Casting Technology

We employ state-of-the-art sand casting processes ensuring consistent quality output:

Automated Molding Lines: High-pressure green sand molding for mass production with dimensional stability within CT8-10

Resin Sand Systems: Furan no-bake and alkaline phenolic binders for complex geometries and superior surface finish

Integrated Pattern Shop: CAD/CAM designed patterns with 3D printed prototypes for rapid development

Spectrometer Monitoring: Real-time chemical composition control during melting in medium-frequency induction furnaces

Complete Design and Mold Manufacturing

Our integrated approach provides significant advantages:

DFM (Design for Manufacturing) Analysis: Early-stage engineering support to optimize part design and reduce production costs

Pattern and Mold Fabrication: In-house tooling department manufacturing precision patterns and core boxes

Solidification Simulation: Advanced software predicting and preventing potential casting defects before production

Rapid Prototyping: Functional sample delivery within 2-3 weeks for design verification

Quality Assurance and Secondary Processing

Every component undergoes rigorous quality control:

Dimensional Inspection: CMM verification maintaining tolerances to ISO 8062 standards

Non-Destructive Testing: Magnetic particle and ultrasonic examination for critical applications

Complete Machining Capability: CNC machining centers performing turning, milling, and drilling operations

Surface Treatment: Shot blasting, painting, and anti-corrosion coatings available

Global Industrial Applications

Our cast components serve multiple sectors:

Agricultural Machinery: Gearboxes, transmission housings, and harvester components

Construction Equipment: Counterweights, boom arms, and structural frames

Industrial Machinery: Press frames, machine tool bases, and hydraulic valve bodies

Power Transmission: Pulleys, sheaves, and gear blanks

Partner with our Chinese foundry for reliable iron and steel sand casting solutions. Our comprehensive service - from engineering design to factory mold making and final production - ensures you receive high-quality components that meet international standards while maintaining competitive pricing and reliable delivery schedules.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |