Experienced China Mass Production of Aluminum Diecast Casting Parts Offering Quality Die Casting Services

- Overview

- Recommended Products

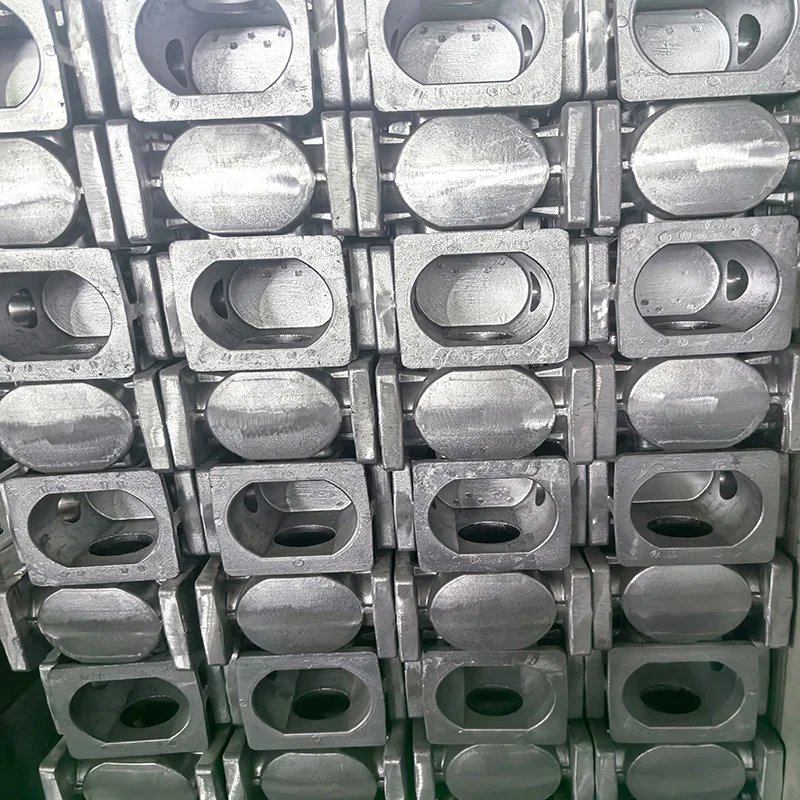

China's aluminum die casting industry has established global leadership in mass-producing high-precision components through advanced manufacturing capabilities and decades of technical expertise. Our specialized die casting services deliver exceptional quality parts for diverse industrial applications, combining sophisticated production techniques with rigorous quality control systems.

Premium Material Selection

We utilize high-performance aluminum alloys including ADC12, A380, and A360, selected for their superior mechanical properties and casting characteristics. These materials provide excellent fluidity during casting, outstanding corrosion resistance, and remarkable strength-to-weight ratios. The aluminum components demonstrate tensile strength ranging from 270-310 MPa, with melting points optimized for die casting processes between 580-680°C.

Advanced Production Technology

Our manufacturing process employs 800-ton to 2000-ton cold chamber die casting machines equipped with real-time monitoring systems. The production integrates automated molten metal delivery, precision temperature control, and robotic part extraction. We implement vacuum-assisted high-pressure die casting technology that achieves casting pressures up to 100 MPa, significantly reducing porosity and enhancing mechanical properties.

Precision Engineering Applications

The mass-produced aluminum diecast components serve critical functions across multiple industries:

Automotive: Engine brackets, transmission housings, and electric vehicle battery enclosures

Consumer Electronics: Smartphone frames, laptop chassis, and heat dissipation components

Industrial Equipment: Pump housings, motor frames, and hydraulic system components

Telecommunications: 5G antenna housings and base station structural parts

Quality Assurance Excellence

Our comprehensive quality management system includes:

In-process dimensional verification using optical comparators

X-ray inspection for internal defect detection

CMM measurement ensuring dimensional accuracy within ±0.05mm

Material certification and mechanical property testing

With extensive experience in high-volume production, we maintain consistent output of 500,000+ components monthly while ensuring each part meets international quality standards. Our technical team provides design-for-manufacturability support, optimizing part geometry for enhanced performance and cost efficiency.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |