- Overview

- Recommended Products

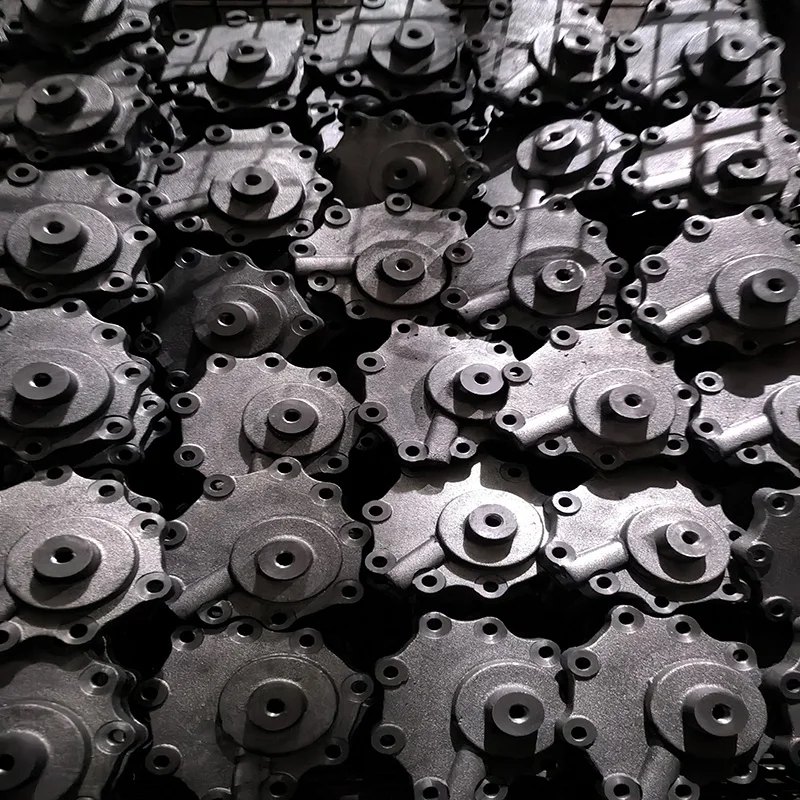

In demanding industrial environments where corrosion resistance and mechanical strength are paramount, Grade 1.4408 stainless steel stands as a premium martensitic alloy for critical components. Our specialized foundry provides Customized 1.4408 Stainless Steel Casting Services, delivering precision factory products that excel in harsh operating conditions. We combine metallurgical expertise with advanced manufacturing to produce castings that offer exceptional performance in chemical processing, power generation, and marine applications.

Premium Material Properties of 1.4408 Stainless Steel

Grade 1.4408 (equivalent to CA15M/AISI 416) offers a superior combination of properties:

Excellent Corrosion Resistance: Withstands moderate corrosive environments including mild acids, alkalis, and marine atmospheres

High Strength and Hardness: Delivers tensile strength of 850-1000 MPa and hardness up to 24 HRC in heat-treated condition

Good Wear Resistance: Maintains surface integrity under abrasive conditions

Optimized Machinability: Superior to standard stainless grades, reducing secondary processing costs

Heat Treatable: Can be hardened through quenching and tempering for enhanced mechanical properties

Advanced Manufacturing Process and Quality Control

Our comprehensive casting methodology ensures superior quality:

Precision Sand Casting: Resin sand molding produces components with excellent surface finish and dimensional accuracy

Spectrometer Verification: Real-time chemical analysis ensures precise composition control (C: 0.06% max, Cr: 12-14%, Ni: 1% max)

Controlled Heat Treatment: Quenching and tempering processes optimize mechanical properties

Non-Destructive Testing: Liquid penetrant and magnetic particle inspection guarantee defect-free components

Technical Specifications and Capabilities

Component Weight Range: 1 kg to 500 kg per single casting

Dimensional Tolerance: CT10-12 per ISO 8062 standards

Surface Finish: 6.3-12.5 μm Ra as-cast, improvable to 3.2 μm with processing

Quality Certification: ISO 9001:2015 compliant manufacturing processes

Custom Engineering and Design Support

Our integrated services include:

Design Optimization: Casting simulation and solidification analysis

Pattern Manufacturing: Wood, plastic, and metal patterns for various production volumes

Machining Integration: CNC milling, turning, and grinding capabilities

Surface Treatment: Passivation, polishing, and shot blasting options

Industry Applications and Performance Benefits

Our 1.4408 stainless steel castings serve critical functions in:

Valve and Pump Components: Bodies, impellers, and trim parts for corrosive service

Marine Equipment: Propeller shafts, fitting, and seawater system components

Food Processing: Machinery parts requiring corrosion resistance and cleanability

Chemical Industry: Reactor parts, mixer components, and processing equipment

Partner with our factory for 1.4408 stainless steel castings that deliver uncompromising quality and performance. Our customized approach ensures components that meet your exact specifications while providing the corrosion resistance and mechanical strength required for demanding industrial applications.

OEM Service |

Investment Casting |

Die Casting |

Sand Casting |

Stamping/Forging |

||||

Weight |

5g-50kg |

0.5kg-1000kg |

0.5kg-1ton |

|||||

Capacity |

200ton/month |

500ton/month |

1000ton/month |

200ton/month |

||||

Machining tolerance |

±0.01-0.03mm |

±0.02mm |

||||||

Surface roughness |

6.4 Raum/254 Rauinches |

3.2 Raum/125 Rauinches |

12.5 Raum |

|||||

MOQ |

200 pcs |

1000 pcs |

200 pcs |

1000 pcs |

||||

Material for cast |

304 316 stainless steel carbon steel |

A380 A356 aluminum aluminum alloy zinc alloy |

Iron grey iron ductile iron aluminum |

Stainless aluminum brass carbon steel |

||||

Add-Value Service |

Add-Value Service |

|||||||

Coating |

Anodizing Zinc plating |

Paining |

Powder coating |

Electroplating |

||||

Machining |

Machining |

Milling |

Drilling |

Boring |

||||

Cutting&Forming |

Key cutting |

EDM |

Welding |

|||||

Heat Treatment |

Hardening |

Normalizing |

Quenching&Tempering |

Annealing |

||||