- Overview

- Recommended Products

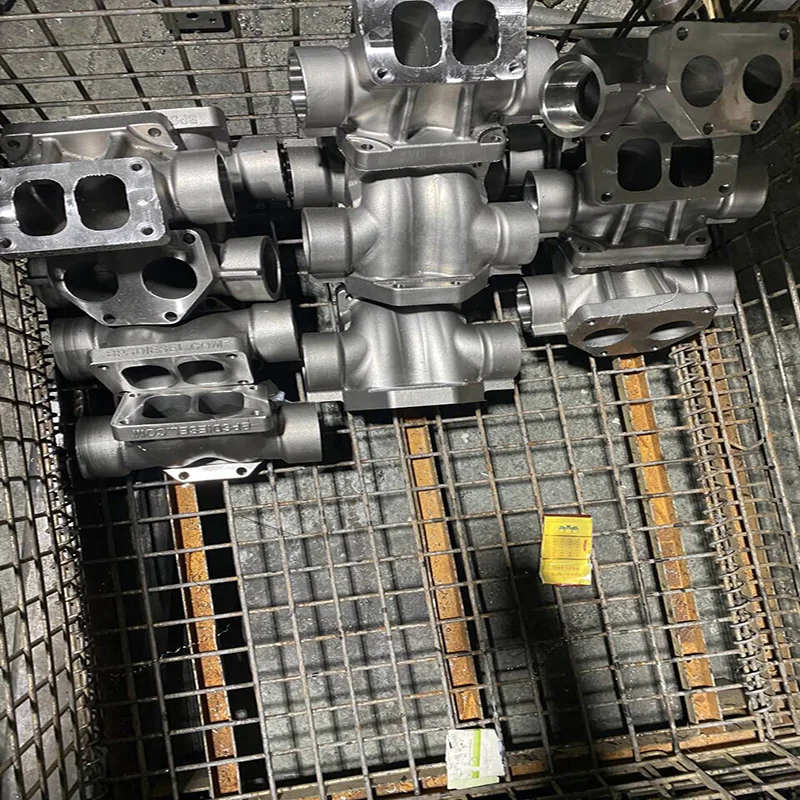

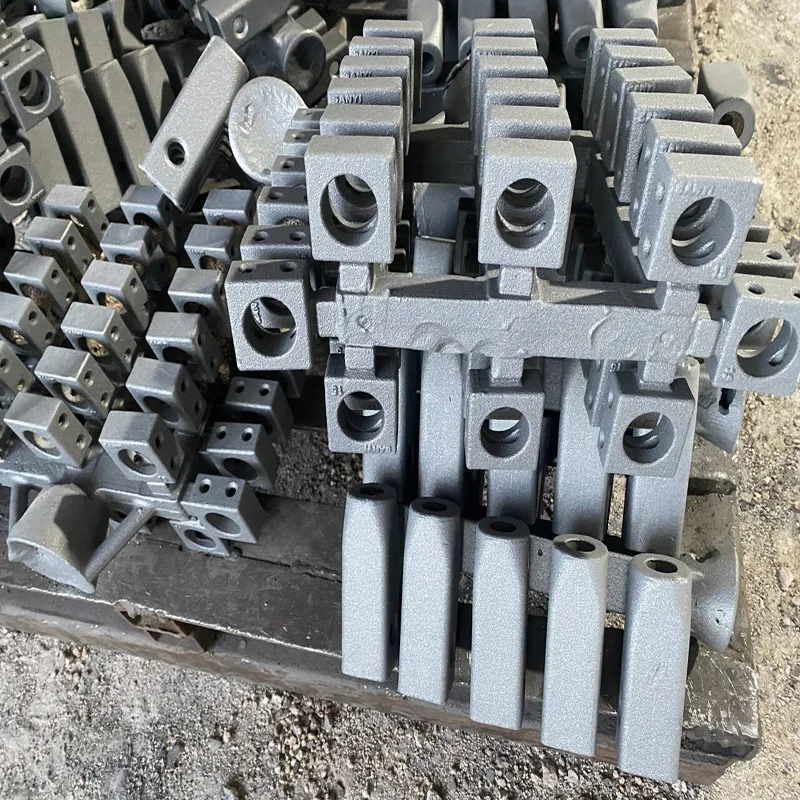

In industrial components where corrosion resistance, structural integrity, and precision are paramount, Customizable 304 & 316 Stainless Steel Casting Services deliver exceptional performance. Our Precision Metalwork capabilities transform these superior alloys into complex, high-tolerance parts that meet the rigorous demands of various harsh environments, providing long-lasting reliability and value.

Superior Material Properties for Challenging Environments

The selection of stainless steel grade is critical to performance. We specialize in the two most versatile austenitic grades:

304 Stainless Steel: Offers excellent corrosion resistance against a wide range of atmospheric and chemical environments. It provides good formability and weldability, making it a versatile and cost-effective choice for numerous applications.

316 Stainless Steel: Enhanced with molybdenum, 316 stainless steel delivers superior resistance to chlorides and acidic compounds, including saltwater. This makes it the ideal material for marine, chemical processing, and other highly corrosive settings. Both grades maintain good mechanical strength and toughness across a range of temperatures.

Advanced Casting and Precision Machining Process

Our integrated manufacturing approach ensures every component meets exact specifications:

Precision Casting: We utilize advanced investment casting (lost-wax) and sand casting techniques to produce near-net-shape components. This allows for the creation of complex geometries, internal passages, and intricate details with minimal material waste and excellent surface finish.

CNC Machining & Finishing: The cast components are brought to their final dimensions through our Precision Metalwork stage. Our state-of-the-art CNC machining centers ensure critical tolerances are held, achieving precise bore alignment, flat sealing surfaces, and perfect fitment. Additional finishing processes, such as passivation, polishing, or electropolishing, are applied to enhance corrosion resistance and achieve the desired aesthetic.

Rigorous Quality Assurance

We implement a multi-stage quality control protocol, including dimensional inspection with CMM, liquid penetrant testing (LPT) for surface defects, and material certification to guarantee every part meets industry standards and your specific requirements.

Wide-Ranging Industrial Applications

Our custom 304 and 316 stainless steel castings are essential in sectors including:

Marine & Offshore: Pump housings, valve bodies, and fittings resistant to saltwater corrosion.

Chemical & Pharmaceutical: Reactor vessels, mixer components, and pipe fittings that handle aggressive chemicals.

Food & Beverage Processing: Sanitary equipment, conveyor parts, and storage tanks that require easy cleaning and contamination resistance.

Medical & Surgical: Durable and biocompatible instrument housings and equipment frames.

Architectural & Construction: High-strength, aesthetically pleasing hardware and structural elements.

By leveraging our Customizable Stainless Steel Casting Services, you secure a reliable supply of high-integrity components that combine the inherent benefits of 304/316 stainless steel with the accuracy of modern precision metalwork, ensuring optimal performance and longevity in your most critical applications.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |