- Overview

- Recommended Products

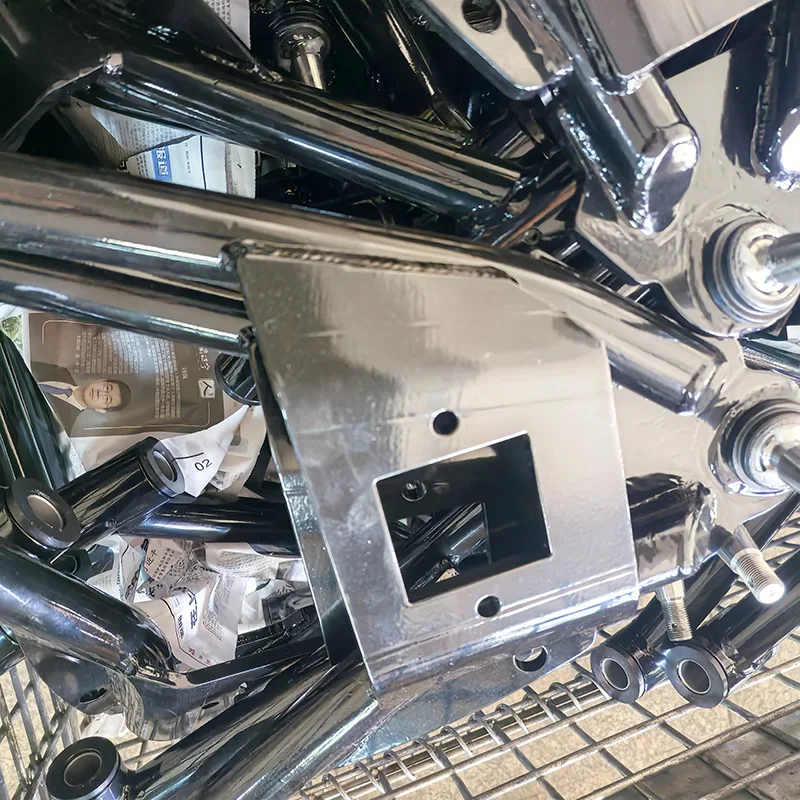

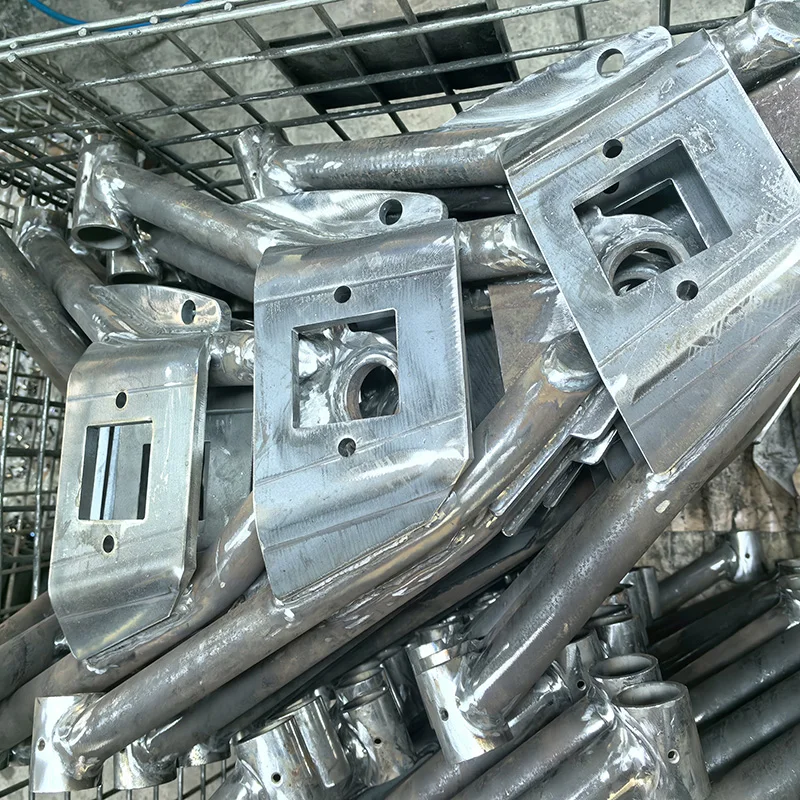

In precision manufacturing environments worldwide, custom stamping and machining of sheet metal parts represents a fundamental process for creating durable, reliable mechanical components. Our specialized services deliver high-quality stamped mechanical parts that combine material excellence with precision engineering, serving diverse industries from automotive to electronics. This comprehensive manufacturing approach transforms flat sheet metal into complex three-dimensional components ready for immediate implementation in various mechanical systems and assemblies.

Material Specifications and Performance Characteristics

We work with multiple material grades including cold-rolled steel (SPCC, DC01-04), galvanized steel (SECC, SGCC), aluminum (5052-H32, 6061-T6), and stainless steel (304, 430). Our cold-rolled steel components provide tensile strength of 270-410 MPa with excellent formability, while galvanized variants add corrosion protection without compromising structural integrity. Aluminum stampings deliver superior strength-to-weight ratios with tensile strength of 140-290 MPa and natural corrosion resistance. Stainless steel parts offer enhanced mechanical properties with tensile strength of 515-620 MPa for demanding environments. All materials maintain consistent mechanical characteristics through production runs, with bending radii achieving 0.4-1.0 times material thickness without cracking.

Precision Stamping and Machining Process

Our manufacturing employs high-speed precision stamping presses ranging from 25 to 500 tons capacity, utilizing progressive and transfer die systems for complex multi-stage operations. The process begins with comprehensive DFM analysis to optimize designs for manufacturability and cost efficiency. We utilize advanced tooling systems manufactured from premium die steels (D2, SKD11) that maintain dimensional stability through production runs exceeding millions of cycles. Precision machining capabilities include CNC milling, turning, and drilling operations that maintain tolerances within ±0.05mm for critical features. Integrated quality monitoring systems including vision inspection and automated dimensional verification ensure consistent adherence to specifications throughout production runs.

Comprehensive Mechanical Applications

Our custom stamped sheet metal parts serve vital functions across multiple sectors including automotive (bracket assemblies, electrical components, structural supports), electronics (enclosures, chassis, shielding components), industrial equipment (machine guards, panel frames, mounting plates), and consumer products (appliance components, hardware fittings). The telecommunications industry utilizes our parts for equipment racks and connector components, while the medical sector specifies our components for device housings and instrument frames. Additional applications include aerospace components, agricultural machinery parts, and renewable energy system components where precision, durability, and reliable performance are essential.

Partner with our manufacturing expertise for custom stamped sheet metal parts that balance precision engineering with production efficiency. Our integrated approach from material selection to finished components ensures mechanical parts that reduce assembly time, enhance product reliability, and provide long-term value across diverse applications, supported by comprehensive quality documentation and engineering collaboration.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |