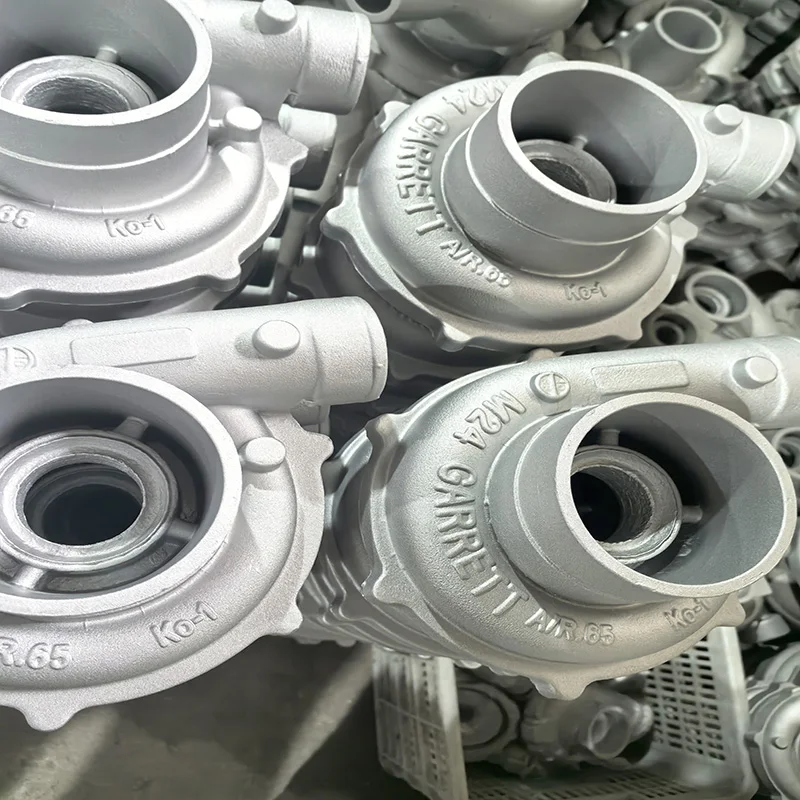

Custom High Precision Aluminum Investment Casting with Powder Coated Finish OEM/ODM Accepted

- Overview

- Recommended Products

In the world of precision manufacturing, achieving complex geometries with exceptional accuracy requires advanced solutions. Our custom high precision aluminum investment casting service delivers exactly that, combining the versatility of aluminum alloys with the unmatched detail of investment casting. With comprehensive OEM/ODM acceptance and a durable powder coated finish, we provide end-to-end manufacturing solutions for industries where quality, durability, and precision are non-negotiable.

Material Excellence: High-Performance Aluminum Alloys

We utilize premium aluminum alloys to meet diverse application demands:

A356-T6: Excellent strength-to-weight ratio, outstanding corrosion resistance, and superior machinability

360.0: High fluidity for complex thin-walled components, good pressure tightness

413.0: Superior corrosion resistance and excellent casting characteristics

Custom Alloys: Tailored compositions to meet specific mechanical or thermal requirements

Advanced Manufacturing Process

Our integrated approach ensures superior quality at every stage:

-

Investment Casting Process:

Precision wax pattern creation using injection molding

Multi-layer ceramic shell building for dimensional stability

Controlled dewaxing and firing processes

Vacuum-assisted pouring for defect-free castings

-

CNC Machining:

5-axis machining centers for complex geometries

Tight tolerance maintenance (±0.01mm)

Precision finishing of critical features and mounting surfaces

-

Heat Treatment:

Solution heat treatment and artificial aging (T6 temper)

Stress relieving for dimensional stability

Enhanced mechanical properties optimization

-

Powder Coating:

Multi-stage pre-treatment including degreasing and chromating

Electrostatic application for uniform coverage

Thermal curing for enhanced adhesion and durability

Performance Advantages

Complex Geometry Capability: Produces intricate shapes with internal passages

Exceptional Surface Finish: As-cast surface quality of Ra 3.2 μm or better

High Dimensional Accuracy: Consistent repeatability across production runs

Superior Corrosion Protection: Combined material and coating protection

Weight Reduction: Optimal strength-to-weight ratio for lightweight designs

Quality Assurance

ISO 9001:2015 certified quality management system

First article inspection and in-process quality control

X-ray and dye penetrant testing available

Full material traceability and certification

Applications

Aerospace: Turbine blades, structural components, brackets

Medical: Surgical instruments, equipment housings

Automotive: Engine components, transmission parts

Industrial: Valve bodies, pump components, fluid handling systems

Defense: Weapon systems, optical mounts, communication equipment

Partner with us for aluminum investment casting solutions that combine precision engineering with durable protection. Contact us today to discuss your OEM/ODM requirements and discover how our expertise can bring your most challenging designs to life.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |