- Overview

- Recommended Products

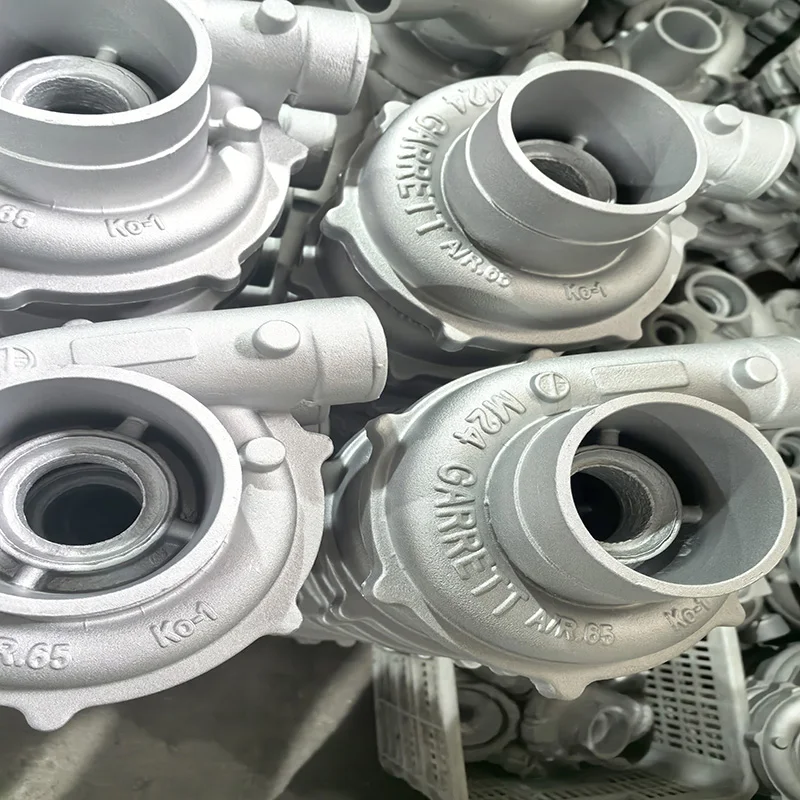

Our CNC machining OEM aluminum casting services provide comprehensive solutions for semi-finishing tools and industrial components. By integrating advanced casting techniques with precision machining capabilities, we deliver aluminum parts that meet the most demanding specifications for dimensional accuracy, surface quality, and mechanical performance in tooling applications.

Material Technology

We utilize high-performance aluminum alloys specifically engineered for semi-finishing tools:

6061-T6 Aluminum: Excellent strength-to-weight ratio and machinability

7075-T6 Aluminum: Superior strength comparable to many steels

A380 Die Casting Alloy: Optimal fluidity and thermal conductivity

2024 Aluminum: High fatigue resistance and toughness

Custom Alloy Blends: Tailored compositions for specific tooling requirements

Integrated Manufacturing Process

Our combined casting and machining approach ensures complete manufacturing solutions:

Aluminum Casting Phase

Pattern Design: CAD/CAM engineered molds with shrinkage compensation

Casting Method Selection: High-pressure die casting for complex geometries

Controlled Solidification: Optimized cooling rates for uniform microstructure

Quality Inspection: Initial dimensional and visual examination

CNC Machining Operations

3-5 axis machining centers for complex contours

Precision milling of critical functional surfaces

High-speed drilling and tapping operations

Coordinate measuring machine validation

Surface treatment preparation

Performance Characteristics

Dimensional Precision: ±0.05mm tolerance achievement

Surface Finish: Ra 0.8-1.6μm on critical tool surfaces

Mechanical Strength: 250-570 MPa tensile strength range

Thermal Stability: Maintains accuracy under operating temperatures

Wear Resistance: Excellent durability in semi-finishing applications

Weight Optimization: 60% weight reduction compared to steel components

Quality Assurance Protocol

Material certification to ASTM standards

First article inspection and validation

In-process dimensional verification

Surface roughness measurement

Mechanical property testing

Final comprehensive inspection

Industrial Applications

Semi-Finishing Tools: Deburring tools, finishing cutters, and precision gauges

Automotive Fixtures: Jigs and fixtures for assembly operations

Aerospace Tooling: Composite trimming tools and assembly fixtures

Electronic Manufacturing: Test fixtures and production tooling

General Industry: Custom fixtures and specialized tooling components

Technical Advantages

Reduced lead times through integrated manufacturing

Cost-effective production for medium volume requirements

Excellent strength-to-weight ratio for handheld tools

Superior surface quality for precision applications

Design flexibility for complex tool geometries

Consistent performance across production batches

Customization Capabilities

Complete design for manufacturability analysis

Prototype development and testing

Volume production from 100 to 10,000+ units

Multiple surface treatment options

Custom packaging and labeling

Just-in-time delivery programs

Our CNC machining OEM aluminum casting services provide the perfect solution for semi-finishing tools requiring lightweight durability and precision performance. By combining advanced casting technology with precision machining expertise, we deliver components that enhance tooling efficiency, reduce operator fatigue, and improve manufacturing productivity across various industrial applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |