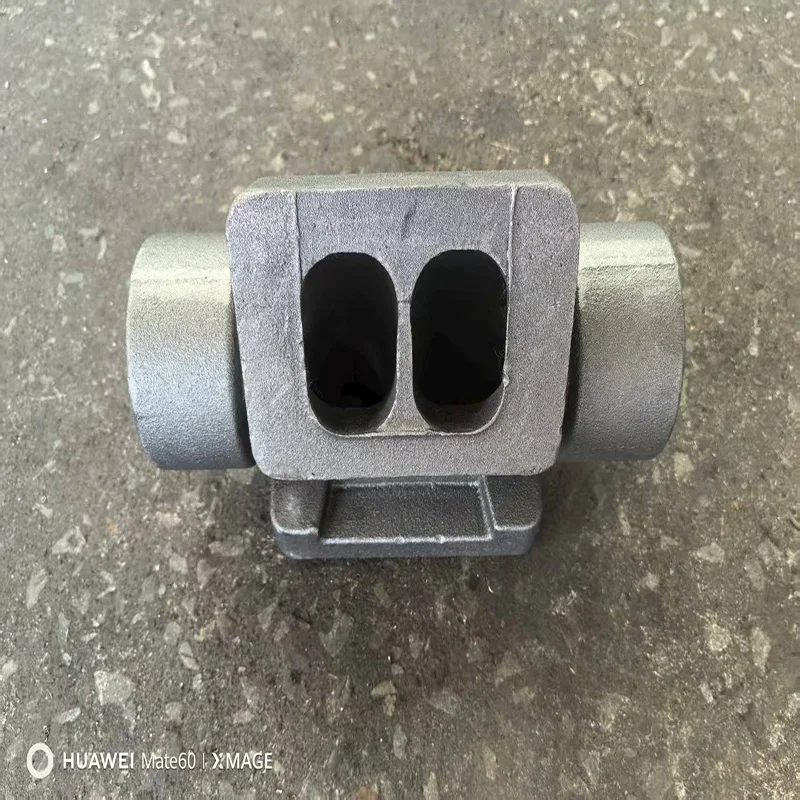

China Leading Foundry Custom Precision Aluminum Sand Casting Water Cooled Marine Exhaust Inlet Manifold High Casting Services

- Overview

- Recommended Products

As China's premier foundry specializing in marine components, we deliver precision-engineered aluminum sand casting solutions for water-cooled exhaust inlet manifolds that withstand the extreme demands of marine operations. Our advanced manufacturing capabilities combine material science excellence with precision engineering to create components that ensure optimal performance in corrosive marine environments.

Advanced Marine-Grade Aluminum Alloys

Our manifolds utilize specialized aluminum formulations:

A356-T6 Marine Alloy with 7.0% silicon content optimized for saltwater corrosion resistance

Cu-Ni modified variants featuring 1.5% copper and 1.0% nickel for enhanced seawater compatibility

Strontium-modified eutectic silicon structure improving mechanical properties in high-humidity conditions

Pressure-tight casting ensuring zero porosity in water-cooling passages

Precision Sand Casting Technology

We employ marine-specific manufacturing processes:

Resin-bonded sand molding using furan no-bake systems for superior dimensional stability

Complex core assembly creating intricate water jacket passages with ±0.4mm accuracy

Controlled gradient pouring preventing thermal stresses in thick-thin section transitions

Five-stage heat treatment achieving optimal T6 temper throughout the component

CNC machining integration maintaining 0.1mm flange flatness for perfect sealing

Marine Performance Engineering

Each manifold incorporates critical marine-specific features:

Integrated water jacket design with optimized flow channels for maximum heat dissipation

Sacrificial anode mounting points strategically placed for corrosion protection

Heavy-duty flange construction resisting distortion under thermal cycling from 20°C to 300°C

Salt-spray resistant surface preparation meeting ISO 12944 C5-M corrosion protection standards

Unified drainage systems preventing water accumulation and freeze damage

Quality Assurance Protocol

Rigorous marine-grade validation includes:

Hydrostatic pressure testing at 6.0 bar for 45 minutes

Thermal shock testing through 1000 cycles between seawater temperature and operating heat

Salt spray corrosion testing exceeding 2000 hours per ASTM B117

Vibration fatigue analysis simulating worst-case marine engine conditions

Metallurgical cross-section analysis verifying microstructure integrity

Marine Application Expertise

Our components serve diverse marine applications:

High-speed commercial vessels and workboat engines

Auxiliary power units for large marine vessels

Pleasure craft and yacht propulsion systems

Fishery and patrol boat engine applications

Technical Partnership Benefits

We provide comprehensive marine engineering support:

Computational fluid dynamics for optimized coolant flow

Finite element analysis for stress distribution optimization

Rapid prototyping with 3-week sample delivery

Full material certification meeting DNV-GL and ABS standards

Custom pattern development for specific engine configurations

Our aluminum sand casting expertise delivers water-cooled marine exhaust manifolds that combine lightweight construction with exceptional corrosion resistance and thermal management capabilities. The precision sand casting process enables complex internal water passages and optimized external geometries that are essential for reliable marine engine performance.

Contact our marine engineering team to discuss your specific water-cooled exhaust manifold requirements. As China's leading foundry for marine components, we provide complete technical support and manufacturing solutions that meet the rigorous demands of marine applications while ensuring long-term reliability in challenging operating environments.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |