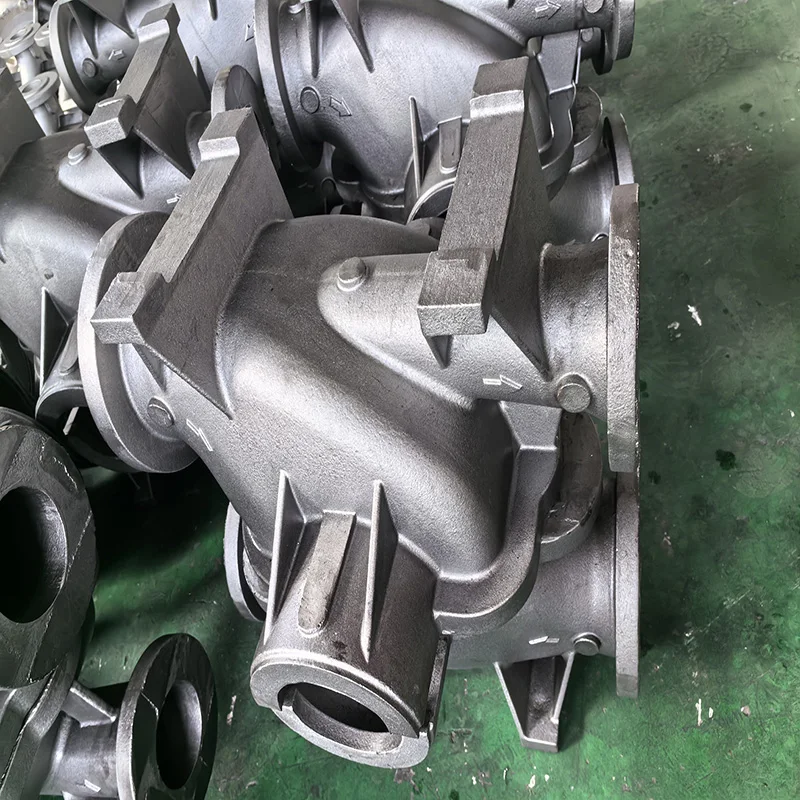

OEM Customized Gray Iron Casting Foundry Resin Sand Casting Genuine Forklift Parts Casting Services

- Overview

- Recommended Products

As a dedicated OEM foundry, we provide customized gray iron casting solutions specifically engineered for the demanding material handling industry. Our specialized resin sand casting process is the cornerstone of manufacturing genuine forklift parts that deliver unmatched durability, reliability, and performance under continuous heavy loads and impact stress.

Premium Material: High-Grade Gray Iron

We utilize high-strength gray iron alloys (e.g., Class 30/35) known for their exceptional performance characteristics vital for forklift applications:

Excellent Wear Resistance: Withstands constant abrasion from pallets, tracks, and other components, ensuring a long service life for parts like axle housings and bearing blocks.

Superior Vibration Damping: The graphite flake structure inherent to gray iron effectively absorbs operational shocks and vibrations, protecting the entire forklift powertrain and enhancing operator comfort.

High Compressive Strength: Provides the necessary structural integrity to support massive loads without deformation, which is critical for mast components and counterweight brackets.

Good Machinability: Allows for efficient post-casting machining to achieve precise tolerances on critical mounting surfaces and bore diameters.

Advanced Production: Resin Sand Casting Process

Our resin sand casting technique offers the ideal balance of flexibility, precision, and cost-effectiveness for low to medium-volume production runs typical in the forklift industry.

Pattern & Mold Creation: We craft precise patterns from wood, plastic, or metal. These are used to form molds from resin-bonded sand, which provides excellent dimensional accuracy and a superior surface finish compared to green sand.

Core Making: Complex internal geometries—such as coolant passages or oil galleries—are created using solid resin sand cores, ensuring structural integrity in hollow sections.

Pouring & Solidification: Molten gray iron is poured into the molds under controlled conditions to achieve optimal metallurgical properties and prevent defects.

Finishing & Quality Assurance: Castings are cleaned, and critical surfaces are machined to specification. Each part undergoes rigorous inspection to ensure it meets OEM standards for performance and safety.

Proven Applications for Genuine Forklift Parts

Our castings are trusted components in a wide range of genuine forklift parts, including:

Drive & Steering Axle Housings

Counterweight Sections and Brackets

Mast Rollers, Channels, and Brackets

Transmission Cases and Differential Carriers

Wheel Hubs and Brake Drums

Partner with our specialized foundry for your OEM customized gray iron casting needs. We deliver genuine forklift parts that are built to last, ensuring the reliability and productivity of your material handling equipment.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |