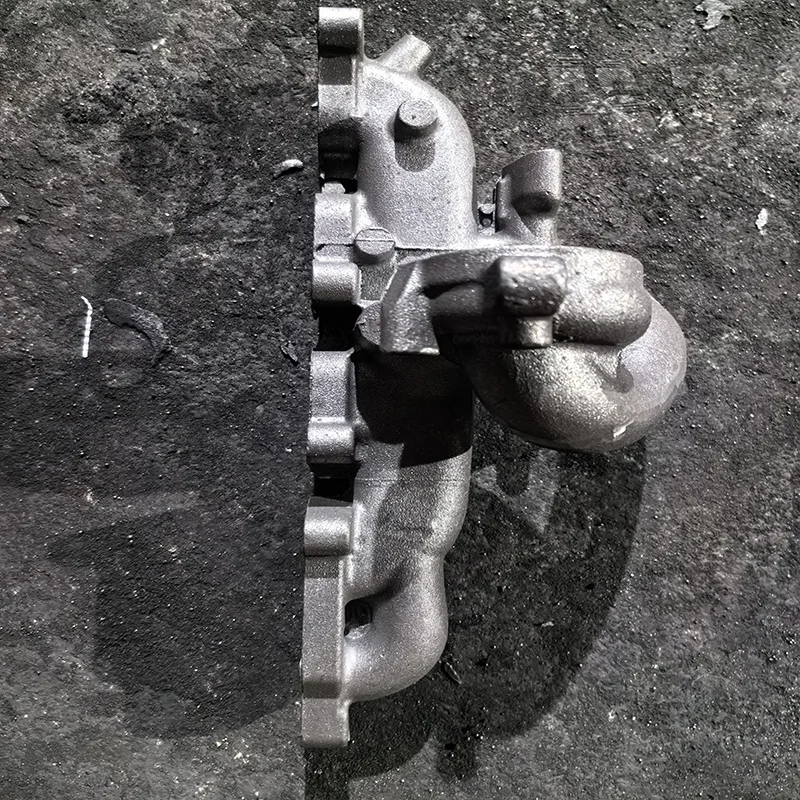

High Quality Standard Size Universal Turbo Manifold Casting Services for Universal Car Type 4BG1 6BG1 Exhaust Manifold

- Overview

- Recommended Products

For automotive engineers and performance specialists working with Isuzu 4BG1 and 6BG1 engine platforms, achieving optimal turbocharger performance requires precisely engineered exhaust components. Our high-quality universal turbo manifold casting services deliver standard-size solutions that combine advanced metallurgy with precision manufacturing techniques, ensuring reliable performance across various automotive applications.

Advanced Material Engineering

Our turbo manifolds are manufactured using premium-grade ductile iron with high nickel-chromium alloy content, specifically formulated to withstand extreme thermal cycling conditions. The material composition features:

Superior thermal fatigue resistance maintaining structural integrity through 1000+ cycles at 850°C

Enhanced creep resistance preventing deformation under sustained boost pressure

Optimal oxidation resistance through stable chromium oxide layer formation

Exceptional vibration damping characteristics crucial for turbocharger applications

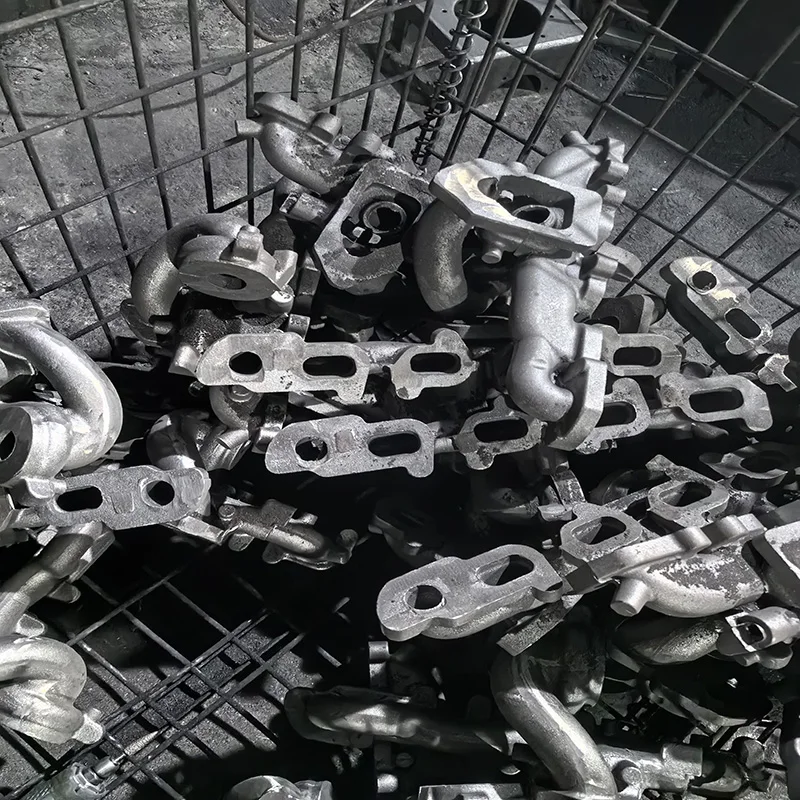

Precision Manufacturing Process

We employ advanced sand-casting techniques combined with sophisticated molding technology to ensure dimensional accuracy and consistent quality. Our manufacturing process incorporates:

CAD-optimized runner designs with computational fluid dynamics analysis

High-pressure molding systems ensuring uniform density and wall thickness

Precision CNC machining of all critical surfaces including flange interfaces

Automated quality control systems verifying dimensional tolerances within ±0.2mm

Performance-Enhancing Features

The universal turbo manifold design incorporates several critical performance elements:

Equal-length runner configuration optimizing exhaust pulse separation

Strategically reinforced turbo flange preventing warping under thermal stress

Smooth internal passageways minimizing exhaust flow turbulence

Standardized mounting pattern accommodating various turbocharger configurations

Integrated wastegate provisions for precise boost control management

Quality Assurance Protocol

Each manifold undergoes comprehensive validation testing including:

Pressure testing to 5 bar for leak prevention verification

Thermal cycling between 150-800°C for durability assessment

Coordinate measuring machine inspection of all critical dimensions

Magnetic particle testing for surface defect detection

Metallurgical analysis confirming material composition compliance

Universal Application Compatibility

Our casting services specialize in components for:

Isuzu 4BG1 and 6BG1 engine platforms across multiple vehicle types

Both OEM replacement and performance upgrade applications

Various industrial and automotive configurations

Custom requirements with rapid prototyping capabilities

Technical Partnership Benefits

We provide comprehensive engineering support including:

Computational fluid dynamics analysis for performance optimization

Rapid prototyping services with 3-week delivery capability

Production capacity from prototypes to volume manufacturing

Complete technical documentation and certification packages

For universal turbo manifold solutions that combine advanced materials with precision manufacturing, contact our engineering team to discuss your specific 4BG1/6BG1 application requirements. Our casting services deliver the perfect balance of performance, reliability, and technical excellence for your automotive projects.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |