- Overview

- Recommended Products

In fluid control systems where precision and corrosion resistance are paramount, the valve disc serves as a critical component determining overall system performance and longevity. Our specialized Aluminium Casting Valve Disc Non-Ferrous Metal Casting Services deliver precision-engineered solutions that meet the stringent requirements of modern fluid handling applications. Through advanced non-ferrous metallurgy and precision casting techniques, we produce valve discs that ensure optimal sealing characteristics, exceptional durability, and reliable performance across various industrial environments.

Advanced Material Engineering

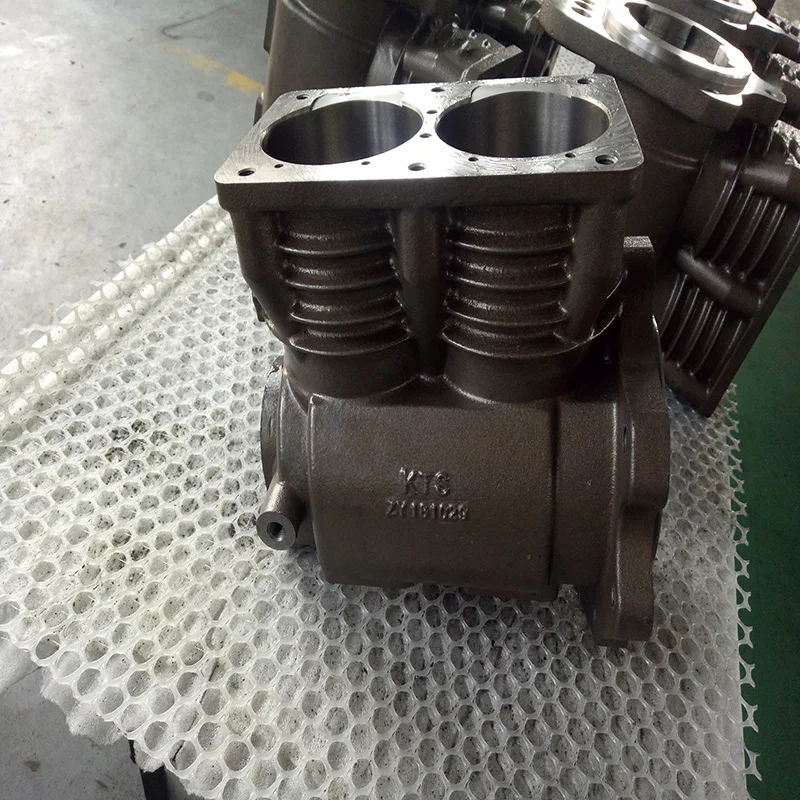

We utilize high-performance aluminum alloys specifically formulated for valve applications, primarily A356.2, 319, and 535 alloys. The A356.2 alloy, when subjected to T6 heat treatment, develops enhanced mechanical properties with typical tensile strength of 310 MPa and yield strength of 220 MPa, providing exceptional structural integrity under pressure differentials. These materials offer excellent corrosion resistance against water, chemicals, and hydrocarbons, superior thermal conductivity for efficient heat dissipation, and natural galvanic compatibility with common valve body materials. The alloys' specific composition ensures minimal porosity and optimal microstructure for machining precise sealing surfaces and complex geometric features.

Precision Casting Manufacturing Process

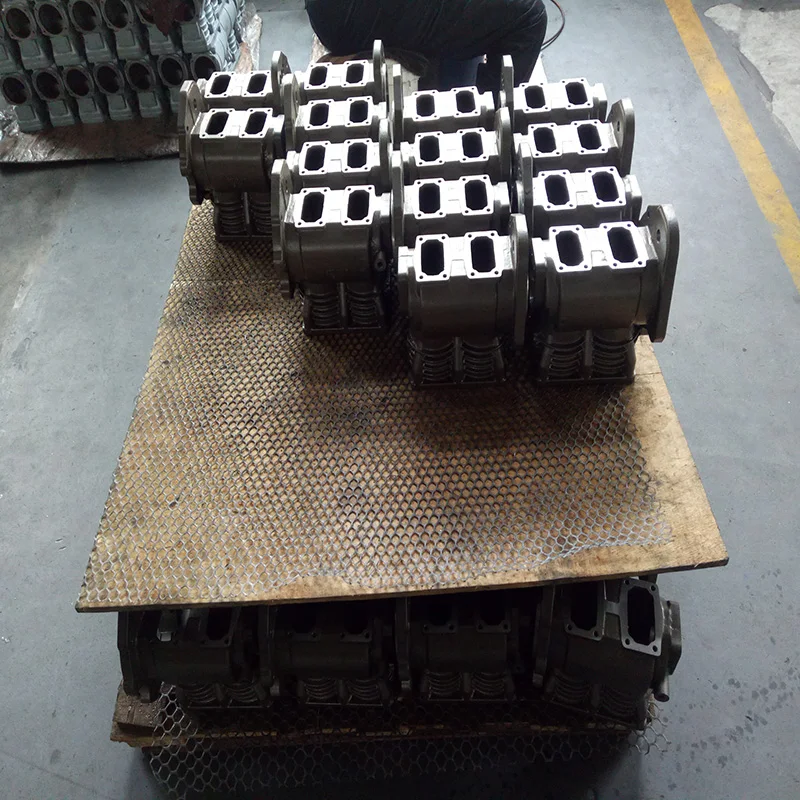

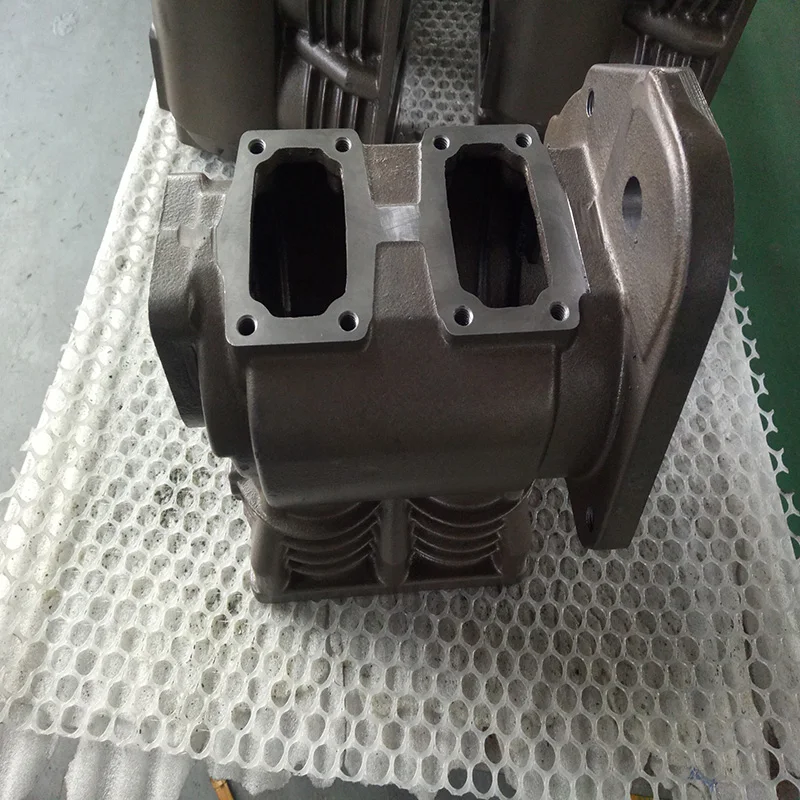

Our manufacturing employs both permanent mold casting and investment casting processes tailored to valve disc specifications. The permanent mold casting process utilizes precision-machined steel molds with advanced coating systems to achieve consistent dimensional accuracy and superior surface finish. For complex disc geometries with intricate features, our investment casting process creates near-net-shape components with exceptional detail resolution. Both processes incorporate controlled solidification technology to ensure directional solidification patterns that minimize shrinkage defects in critical sealing areas. Post-casting operations include precision CNC machining of seating surfaces, stem bores, and alignment features, ensuring perfect dimensional conformity and surface finish requirements for bubble-tight sealing.

Enhanced Performance Characteristics

Valve discs produced through our aluminum casting services deliver:

Superior corrosion resistance in aqueous, chemical, and hydrocarbon services

Excellent strength-to-weight ratio reducing overall valve operating torque

Optimal thermal properties maintaining dimensional stability under temperature variations

Precision-machined sealing surfaces ensuring leak-free performance

Excellent wear resistance against repeated opening and closing cycles

Reduced inertial mass enabling faster valve actuation response

Comprehensive Industrial Applications

Our aluminum casting valve discs serve critical functions across multiple sectors:

Water Treatment Systems: Butterfly valve discs for water distribution and treatment

Chemical Processing: Control valve discs for corrosive media handling

Oil and Gas Industry: Ball valve segments and gate valve discs for hydrocarbon services

Marine Applications: seawater valve components and shipboard system valves

HVAC Systems: Control valve discs for heating, ventilation, and air conditioning

Industrial Processing: Regulating valve discs for various industrial fluids

By choosing our Aluminium Casting Valve Disc Non-Ferrous Metal Casting Services, you secure components engineered for maximum reliability in fluid control applications. Our technical expertise ensures each valve disc delivers optimal flow characteristics, extended service life, and perfect sealing performance, supported by comprehensive material certification and performance validation testing.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |