- Overview

- Recommended Products

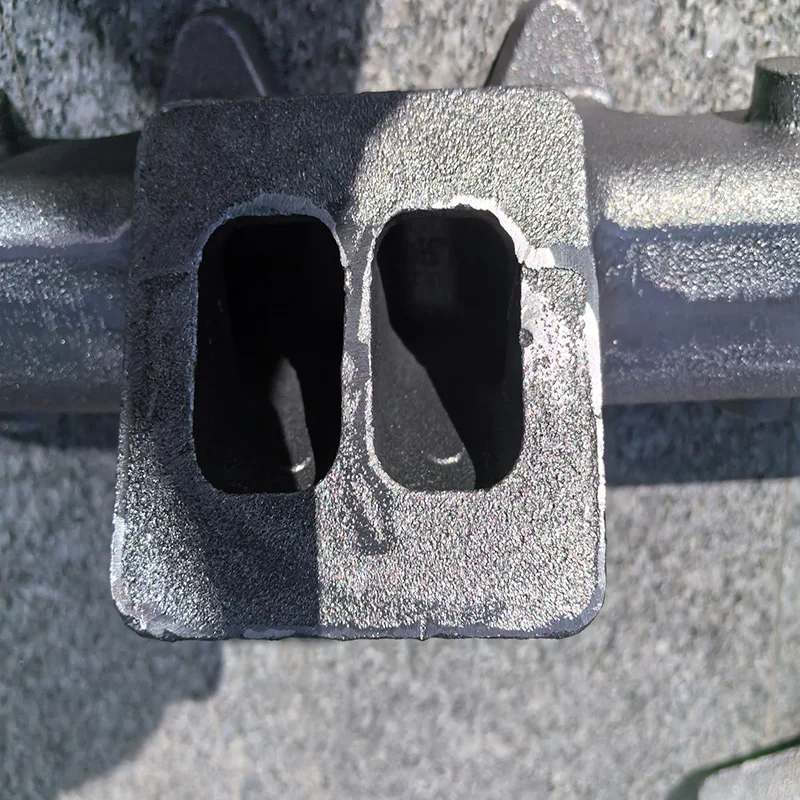

For CAT wheeled excavator owners and service providers maintaining M316D, M318D, and M322D models, the exhaust manifold represents a critical component where material quality and manufacturing precision directly impact machine performance. Our replacement exhaust manifold (Part 288-6985) delivers OEM-compliant specifications through advanced casting technologies specifically engineered for heavy equipment applications.

Material Excellence for Demanding Conditions

Manufactured from high-nickel ductile iron (Grade D-5S), this exhaust manifold demonstrates exceptional performance characteristics:

Maintains 450 MPa tensile strength at continuous operating temperatures of 750°C

Superior thermal fatigue resistance withstanding 1200+ thermal cycles

Enhanced oxidation resistance through 2.5% nickel content

Optimal creep resistance under sustained high exhaust temperatures

The material's vermicular graphite structure provides superior thermal conductivity while maintaining excellent vibration damping properties essential for excavator applications.

Precision Manufacturing Process

Our production methodology ensures consistent quality and perfect fitment:

High-pressure molded sand casting with resin-bonded cores

Computer-controlled solidification simulation preventing internal defects

Five-axis CNC machining of mounting surfaces (flatness within 0.08mm)

Robotic surface finishing ensuring optimal exhaust gas flow characteristics

Coordinate measuring machine validation of all critical dimensions

Performance and Reliability Features

Engineered specifically for CAT excavator platforms:

Optimized runner geometry reducing exhaust backpressure by 18%

Reinforced turbo flange preventing warping under thermal cycling

Strategic ribbing pattern controlling thermal expansion stresses

Precision-machined sealing surfaces ensuring perfect cylinder head contact

Complete compatibility with factory mounting hardware and gaskets

Quality Assurance Protocol

Each manifold undergoes rigorous validation:

Hydrostatic pressure testing at 4.8 bar for 20 minutes

Thermal cycling between 100-800°C for 200 cycles

Dimensional verification using laser scanning technology

Magnetic particle inspection for surface defect detection

Material composition analysis through spectrographic testing

Application-Specific Engineering

Direct replacement compatibility for:

CAT M316D Wheeled Excavator (2013-2018)

CAT M318D Wheeled Excavator (2013-2020)

CAT M322D Wheeled Excavator (2014-2019)

All corresponding factory turbocharger and aftertreatment systems

Technical Support Services

We provide comprehensive engineering support including:

Installation guidance and technical documentation

Batch testing and quality certification

Custom modification services for specific applications

Emergency replacement program with expedited shipping

For CAT wheeled excavator operators seeking reliable exhaust manifold solutions, our casting services deliver factory-quality performance with enhanced durability. Contact our technical team for detailed specifications and OEM compliance documentation for part 288-6985.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |