- Overview

- Recommended Products

In the demanding world of pulp and paper production, the consistent performance of core machinery is paramount to profitability and output quality. The Dieffenbacher SWPM 44" Refiner, specifically the 42MK-4 model, is a workhorse in fiber processing, and its critical components are subject to extreme abrasive and impact wear. Our specialized casting services are dedicated to manufacturing and refurbishing replacement parts for this essential machine, ensuring you achieve maximum operational uptime and processing efficiency.

Engineered Materials for Extreme Service

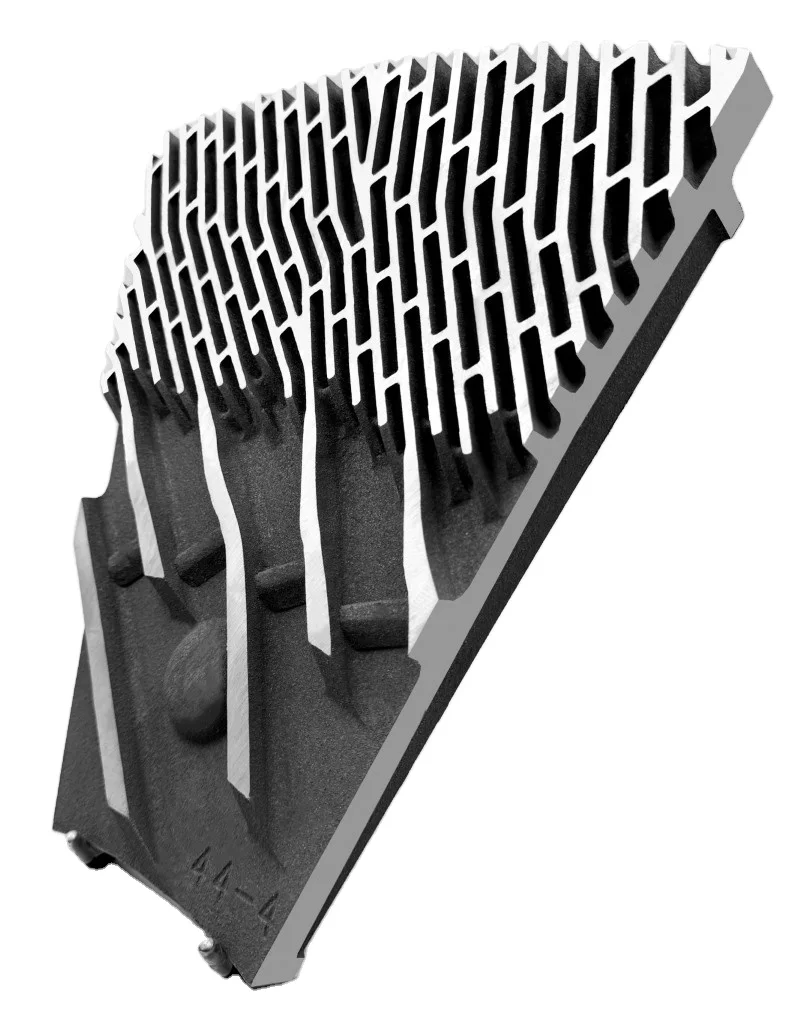

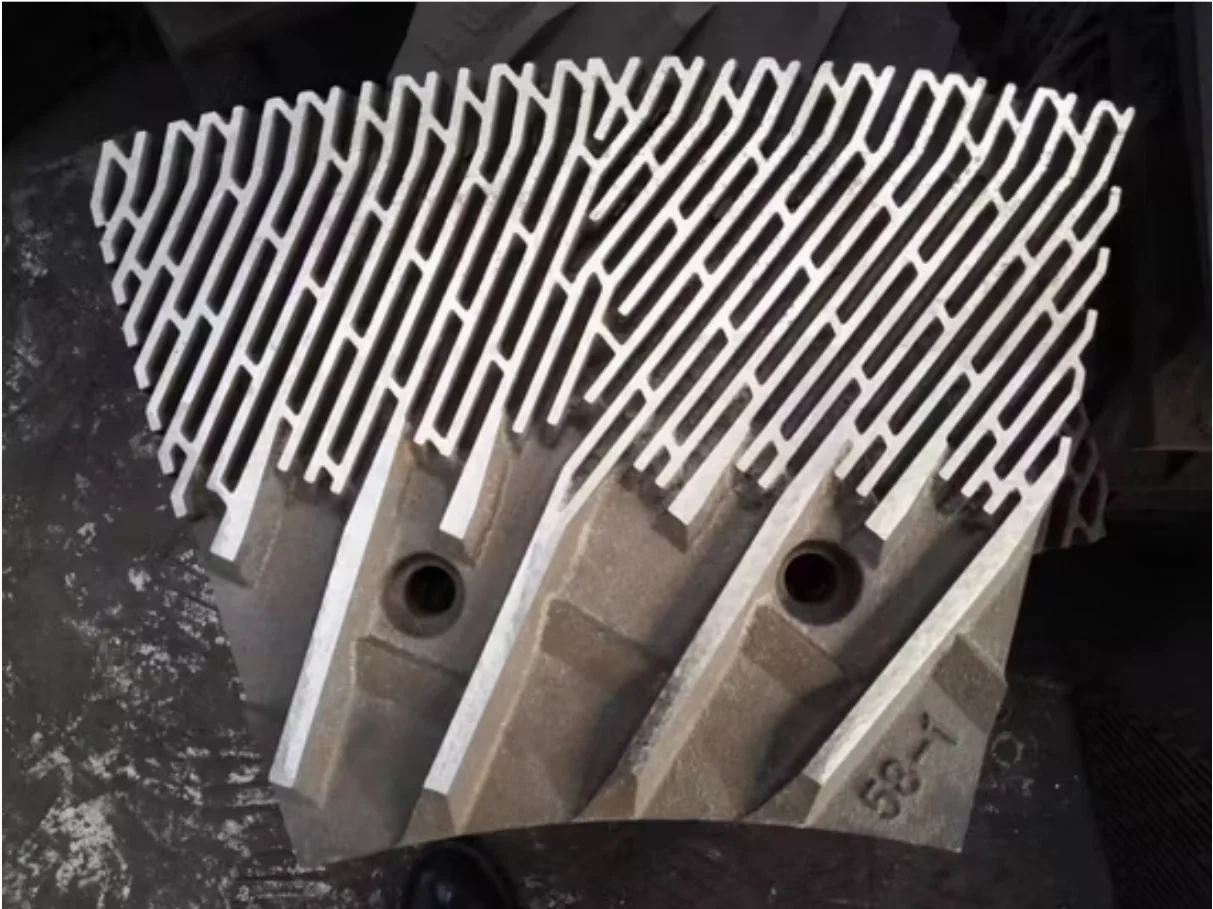

We produce refiner components, such as fill segments, plates, and housing liners, using advanced wear-resistant materials. Our standard offerings include high-chromium white iron, renowned for its exceptional resistance to abrasive wear from wood fibers and contaminants. For the most severe applications, we provide nickel-chrome hard iron alloys, which combine superior abrasion resistance with improved impact toughness. These materials are meticulously selected to withstand the high-impact forces, hydraulic pressure, and continuous friction inside the 44" refining zone, significantly extending service life compared to standard OEM parts.

Precision-Controlled Production and Machining

Our manufacturing process begins with rigorous pattern-making to replicate the precise geometry of the original 42MK-4 components. We employ high-quality resin sand casting to capture intricate details and ensure dimensional stability. Following casting, each part undergoes a controlled heat treatment process to optimize the carbide structure within the iron, achieving the perfect balance of hardness and durability. Critical wear surfaces and mounting interfaces are then finished with precision CNC machining and grinding. This guarantees a perfect fit, proper alignment within the refiner, and consistent fiber processing performance, preventing unscheduled downtime.

Direct Application for Peak Refiner Performance

Our casting services provide a direct, high-performance replacement solution for the Dieffenbacher SWPM 44" Refiner. By using our premium cast components, you can restore your refiner's original processing capacity and fiber quality control. Our parts are engineered to maintain precise plate gaps and withstand the mechanical loads of the refining process, leading to more uniform pulp, reduced energy consumption per ton, and longer intervals between maintenance shutdowns.

Partner with us for reliable, high-performance castings that keep your Dieffenbacher refiner running at peak efficiency. We deliver the durability and precision required to protect your investment and optimize your pulp production line.

Product name: |

Grind segment |

Specification: |

14-16",17-18",20-24",26-30",42-48",52-58",CC450 |

Material: |

Nickel hard alloy Steel |

Usage: |

Inox Stainless Steel Metal |

Color: |

Natural |

Shape: |

Customized Shape |

Feature: |

Durable |

MOQ: |

1 Piece |

Warranty |

3 years |

ANDRITZ, a key player in the MDF and pulp and paper industry, manufacture it’s famous pressurized refining systems. The ANDRITZ single-disc refiners, equipped with the signature swing door design, enhance efficiency for plate changing process. Their comprehensive solution covers everything from debarking and chipping to screening, washing, and refining.

Q1. What is the advantage about your company? |

||||||||

A1. Our company has professional team and professional production line. |

||||||||

Q2. Why should I choose your products? |

||||||||

A2. Our products are high quality and low price. |

||||||||

Q3. The logo and the color can be customized? |

||||||||

A3. Yes, we welcome you to sample custom. |

||||||||

Q4. Any other good service your company can provide? |

||||||||

A4. Yes,we can provide good after-sale and fast delivery. |

||||||||