- Overview

- Recommended Products

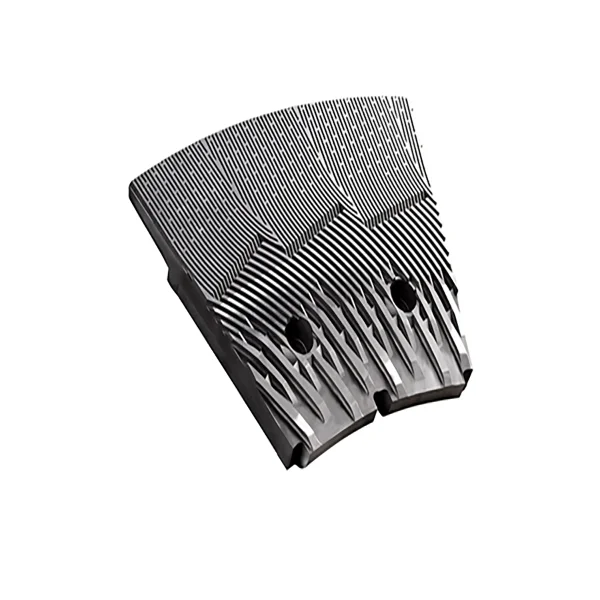

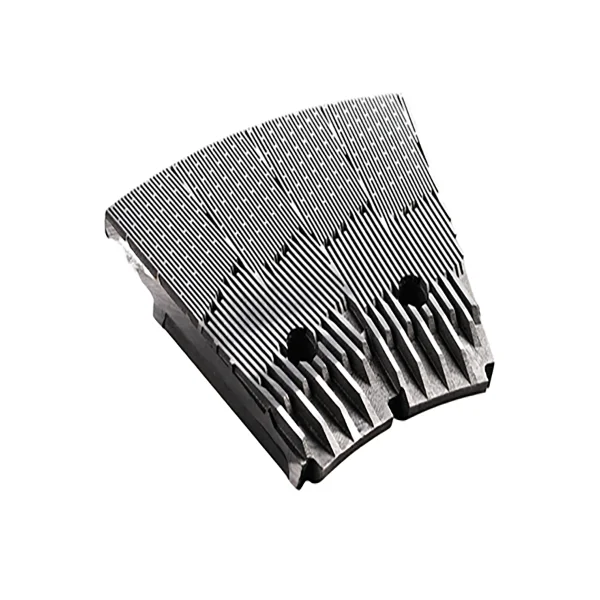

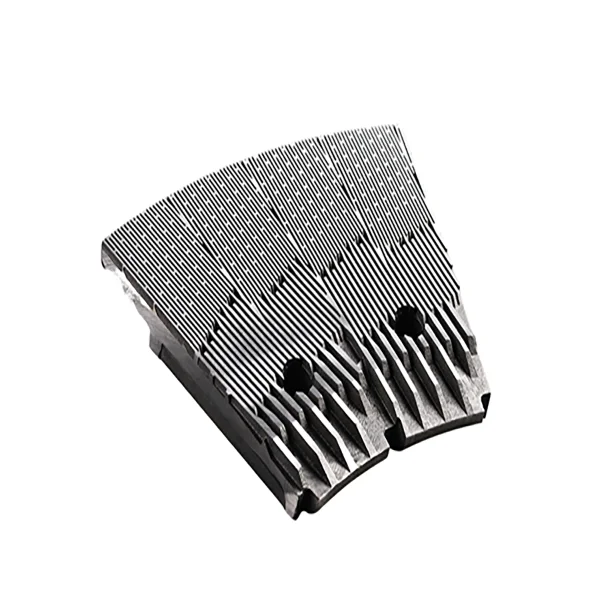

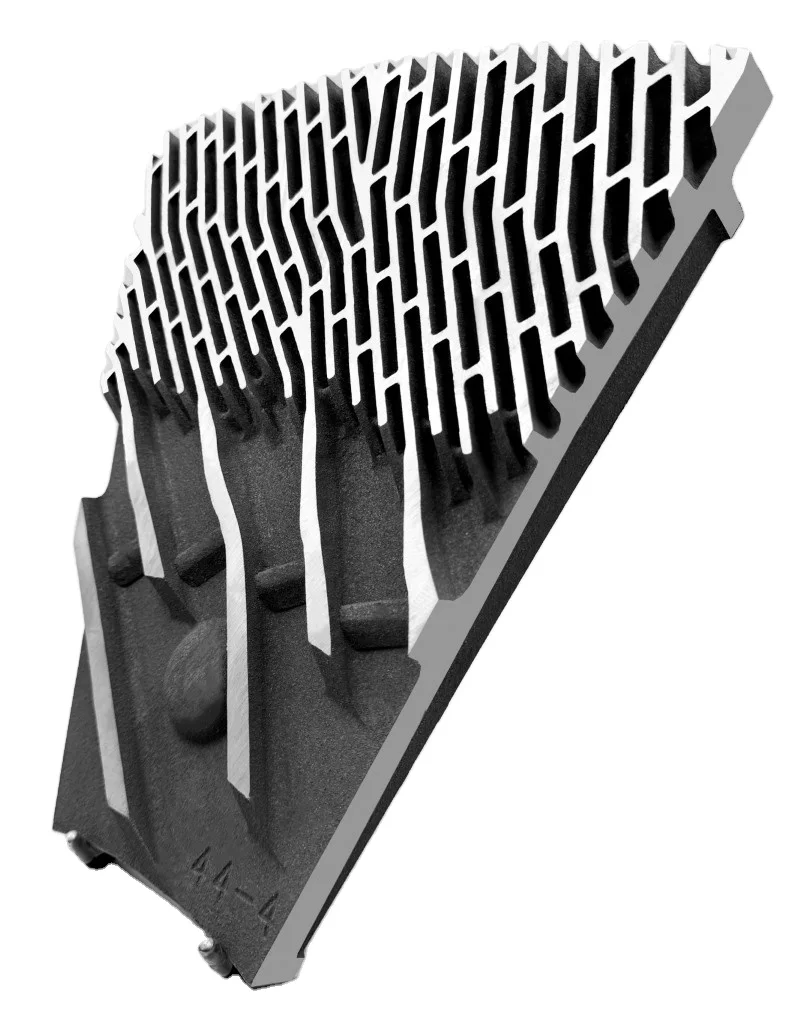

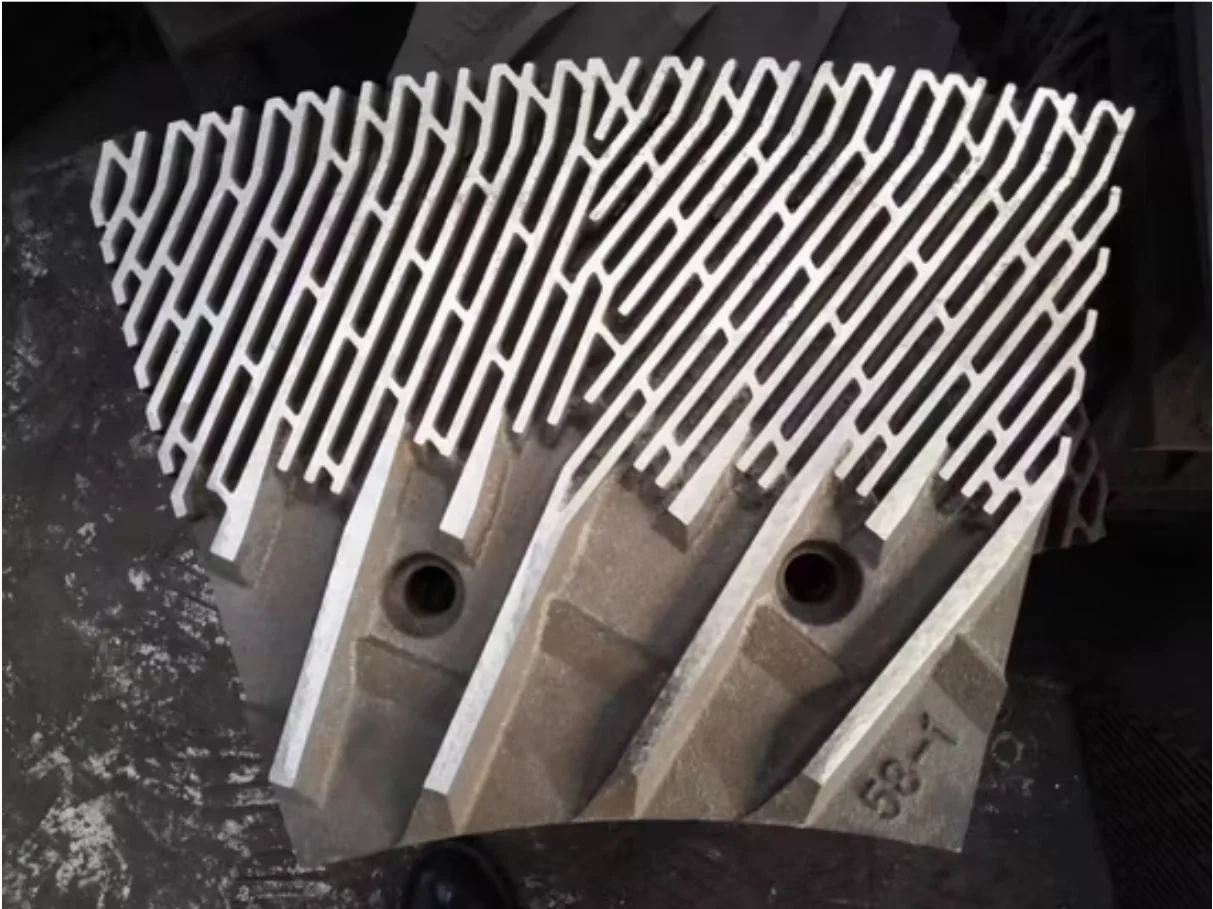

In the pulp and paper industry, consistent refining action is paramount for fiber quality and mill productivity. The Dieffenbacher SWPM 43" Refiner, specifically the 43MK-3 model, is a critical machine where components face extreme abrasive wear. Our specialized casting service is dedicated to manufacturing and refurbishing high-wear parts for this refiner, delivering unmatched durability and precision to minimize downtime and optimize your refining process.

Engineered Materials for Extreme Abrasion Resistance

We produce refiner plates, fill segments, and other wear parts using advanced, high-chromium white iron alloys. These specialized materials are renowned for their exceptional hardness and superior resistance to the relentless abrasive action of wood fibers and contaminants. The specific metallurgical composition is designed to maintain this hardness at elevated operating temperatures, ensuring consistent performance and a significantly extended service life compared to standard OEM parts, thereby reducing your total cost of ownership.

Precision Manufacturing for Optimal Refining Performance

Our process begins with precise pattern-making to replicate the complex geometry of the original 43MK-3 components. We utilize high-quality resin sand casting to ensure dimensional accuracy and surface integrity. Each casting undergoes a controlled heat treatment cycle to develop the optimal carbide structure within the iron, maximizing hardness and impact resistance. The final and most critical step is precision CNC machining, which guarantees the exact tolerances, bar patterns, and mounting surfaces required for perfect fitment and balanced operation within the refiner. This ensures consistent plate gaps and uniform fiber treatment.

Direct Replacement for Enhanced Operational Efficiency

Our casting services provide a direct, high-performance replacement solution for the Dieffenbacher SWPM 43" Refiner-43MK-3. By utilizing our premium cast components, you can restore your refiner's original capacity and fiber development control. Our parts are engineered to withstand the tremendous mechanical and hydraulic forces inside the refining zone, leading to more uniform pulp quality, stable energy consumption, and longer intervals between maintenance shutdowns. This translates directly to increased mill uptime and profitability.

Partner with us for robust, reliable castings that keep your Dieffenbacher refiner operating at peak efficiency. We deliver the wear resistance and precision necessary to protect your refining investment.

Product name: |

Grind segment |

Specification: |

14-16",17-18",20-24",26-30",42-48",52-58",CC450 |

Material: |

Nickel hard alloy Steel |

Usage: |

Inox Stainless Steel Metal |

Color: |

Natural |

Shape: |

Customized Shape |

Feature: |

Durable |

MOQ: |

1 Piece |

Warranty |

3 years |

ANDRITZ, a key player in the MDF and pulp and paper industry, manufacture it’s famous pressurized refining systems. The ANDRITZ single-disc refiners, equipped with the signature swing door design, enhance efficiency for plate changing process. Their comprehensive solution covers everything from debarking and chipping to screening, washing, and refining.

Q1. What is the advantage about your company? |

||||||||

A1. Our company has professional team and professional production line. |

||||||||

Q2. Why should I choose your products? |

||||||||

A2. Our products are high quality and low price. |

||||||||

Q3. The logo and the color can be customized? |

||||||||

A3. Yes, we welcome you to sample custom. |

||||||||

Q4. Any other good service your company can provide? |

||||||||

A4. Yes,we can provide good after-sale and fast delivery. |

||||||||