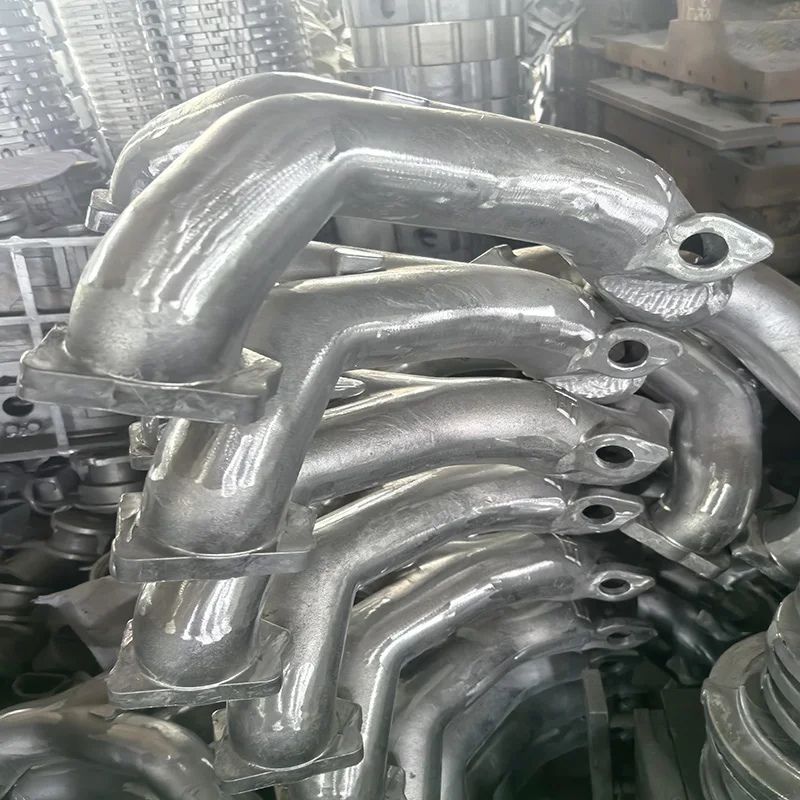

Customized Aluminum Gravity Casting Services with Powder Spraying & Sandblast Anodizing for Machine Parts Customizable

- Overview

- Recommended Products

For engineers seeking a perfect balance of strength, lightweight properties, and superior surface finish, our Customized Aluminum Gravity Casting Services offer a complete manufacturing solution. We specialize in producing high-integrity aluminum components for machinery, enhanced by integrated Powder Spraying and Sandblast Anodizing finishes. This end-to-end process delivers fully finished, highly Customizable parts that excel in both performance and aesthetics, directly to your assembly line.

Premium Aluminum Alloys for Optimal Performance

We utilize high-strength aluminum alloys such as A356 and A380, selected for their exceptional castability and mechanical properties. These alloys provide an excellent strength-to-weight ratio, good corrosion resistance, and high dimensional stability. The result is a component that reduces overall machine weight without compromising on durability, capable of withstanding significant structural and dynamic loads in demanding environments.

Precision Gravity Casting Process

Unlike high-pressure methods, our permanent mold gravity casting process fills the mold calmly, resulting in components with superior metallurgical quality. This technique yields:

Denser Microstructure: Reduced porosity and exceptional mechanical properties.

Excellent Surface Finish: Smother as-cast surfaces that require less finishing effort.

Enhanced Dimensional Accuracy: Consistent production of complex, near-net-shape parts.

This makes it the ideal choice for parts where reliability and structural integrity are paramount.

Integrated Value-Added Surface Finishing

Our service is distinguished by its comprehensive post-casting treatment, providing both corrosion resistance and a premium aesthetic.

Sandblasting: This process creates a uniform, matte surface texture that masks minor imperfections and provides an excellent base for subsequent coatings.

Anodizing (Type II or III): We create a hard, porous anodic layer that is then sealed for extreme surface hardness, excellent wear resistance, and superior corrosion protection. The porous layer can also be dyed in various colors for part identification or branding.

Powder Spraying: Applied after appropriate priming, this coating provides a thick, durable, and attractive polymer layer that is highly resistant to chipping, chemicals, and UV light, available in a vast range of colors and textures.

Broad Industrial Applications

Our finished aluminum castings are ideal for:

Robotics & Automation: Lightweight arms, frames, and housings.

Medical Equipment & Packaging Machinery: Corrosion-resistant, cleanable enclosures.

Optical Device Housings: Aesthetically pleasing and protective casings.

Fluid Power & Pneumatic Systems: Valve bodies, manifolds, and compressor parts.

Partner with us for a streamlined supply chain. We manage your project from mold design and casting through to the final, high-performance finish, delivering a part that is truly ready for actio.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |