- Overview

- Recommended Products

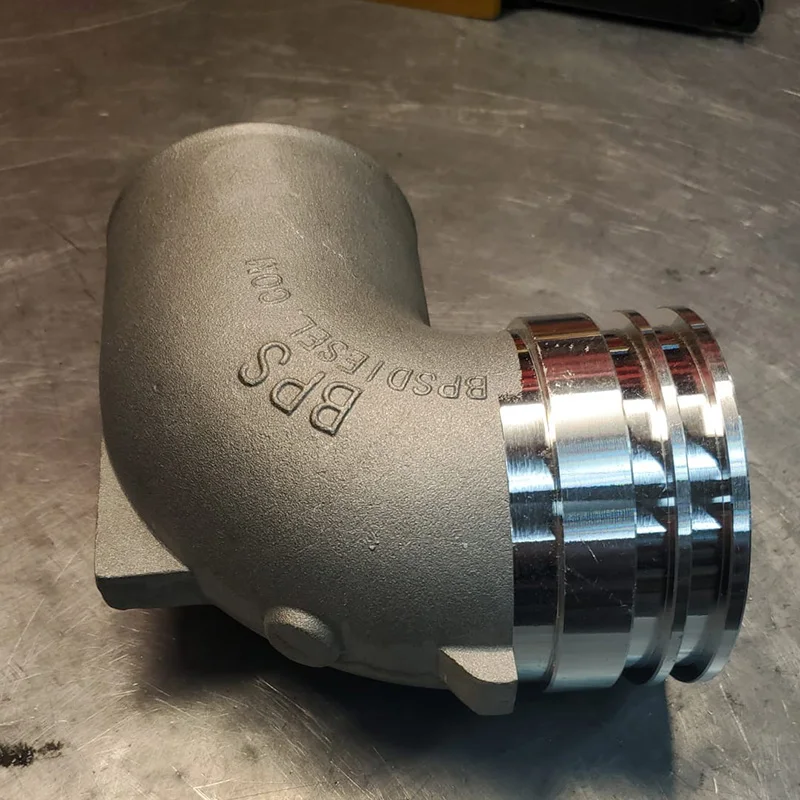

As a specialized manufacturer in aluminum components, we provide comprehensive customized aluminum casting services that combine advanced manufacturing technology with precision engineering. Our premium casting solutions deliver components that excel in performance, durability, and reliability for diverse industrial applications, ensuring optimal results for both prototype development and mass production requirements.

Material Excellence and Performance Characteristics

We utilize premium aluminum alloys specifically selected for their superior casting and mechanical properties. Our A380 aluminum alloy offers an optimal balance of strength and castability with tensile strength of 324 MPa and excellent fluidity characteristics. The ADC12 aluminum alloy provides superior pressure tightness and corrosion resistance with tensile strength of 230 MPa, making it ideal for components requiring leak-proof performance. For applications demanding enhanced mechanical properties, we offer A356-T6 aluminum alloy with tensile strength of 234 MPa after heat treatment, delivering exceptional strength-to-weight ratios and improved elongation characteristics.

Advanced Manufacturing Process

Our production methodology employs state-of-the-art casting technologies:

High-Pressure Die Casting

We utilize advanced cold-chamber die casting machines with precise parameter control, featuring:

Computerized injection systems ensuring consistent quality

Automated molten metal handling for process stability

Multi-stage injection profiling for optimal cavity filling

Real-time monitoring and data acquisition systems

Precision Tooling Engineering

Our mold design incorporates sophisticated elements:

Scientific gating systems for proper metal flow

Advanced cooling channel design for controlled solidification

Strategic venting placement to minimize air entrapment

Durable mold coatings extending tool life

CAD/CAE optimized designs for manufacturability

Quality Assurance and Performance Validation

Each aluminum casting undergoes rigorous quality control:

X-ray inspection for internal defect detection

Coordinate measuring machine dimensional verification

Spectrochemical analysis for material composition

Mechanical property testing confirming specifications

Leak testing for components requiring pressure tightness

Surface finish analysis for optimal performance

Customization Capabilities and Services

Our customized services include:

Engineering support for design optimization

Rapid prototyping for concept validation

Flexible batch sizes from prototypes to mass production

Comprehensive secondary processing

Surface treatment and finishing options

Assembly and testing services

Industrial Applications and Solutions

Our aluminum casting services support diverse industry requirements:

Automotive Industry: Engine components, transmission parts, and structural elements

Aerospace Sector: Lightweight components and structural elements

Electronics: Heat sinks, enclosures, and connector components

Industrial Machinery: Pump housings, valve bodies, and equipment frames

Consumer Products: Appliance components and recreational equipment

By combining advanced aluminum casting technology with comprehensive customization capabilities, we deliver components that optimize performance, reduce weight, and provide cost-effective solutions for demanding applications. Our engineering team collaborates closely with clients to develop casting solutions that meet specific requirements, ensuring perfect fitment, superior performance, and quality-assured operation across various industrial sectors.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |