- Overview

- Recommended Products

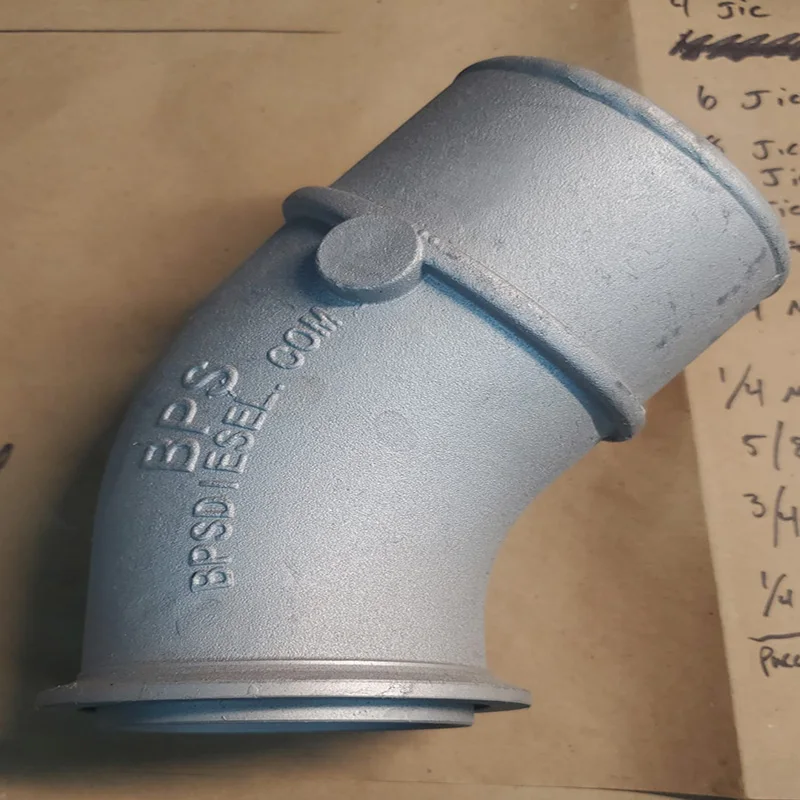

In modern manufacturing, A6061 aluminum stands as a premier choice for high-performance mechanical components. Our specialized A6061 Aluminum Mechanical Parts CNC Machining Service provides precision solutions for Casting Applications, delivering components that combine excellent mechanical properties with outstanding manufacturability. This service bridges the gap between raw casting production and finished, ready-to-install parts, ensuring optimal performance across various industrial sectors.

Superior Material Properties of A6061 Aluminum

A6061 aluminum alloy offers an exceptional balance of characteristics that make it ideal for machined components:

High Strength-to-Weight Ratio: Provides structural integrity while minimizing component weight

Excellent Corrosion Resistance: Withstands harsh environmental conditions without degradation

Good Machinability: Allows for precise CNC machining with superior surface finishes

Thermal Conductivity: Efficient heat dissipation for thermal management applications

Weldability and Formability: Enables versatile manufacturing and assembly options

These properties can be further enhanced through T6 heat treatment, which increases tensile strength to approximately 310 MPa and yield strength to 276 MPa, making A6061 suitable for structural applications.

Precision Manufacturing Process

Our integrated approach combines advanced casting techniques with state-of-the-art CNC machining:

-

Initial Casting Phase

Sand casting for complex geometries and prototype development

Investment casting for superior surface finish and intricate details

High-pressure die casting for high-volume production requirements

-

CNC Machining Operations

5-axis simultaneous machining for complex contours and geometries

High-speed machining achieving tolerances within ±0.01mm

Precision boring, threading, and milling operations

Deburring and edge finishing for optimal performance

-

Quality Assurance Protocol

First-article inspection and statistical process control

CMM verification with 3D scanning capability

Surface roughness measurement and verification

Material certification and mechanical testing

Performance Advantages

Dimensional Stability: Maintains precision under varying temperature conditions

Fatigue Resistance: Withstands cyclic loading in dynamic applications

Cost-Effectiveness: Competitive pricing for both prototype and production quantities

Rapid Turnaround: Efficient processing from design to finished components

Industry Applications

Our A6061 aluminum CNC machining services support diverse sectors:

Automotive Industry: Engine components, brackets, and structural elements

Aerospace Sector: Aircraft fittings, mounting hardware, and instrumentation parts

Electronics Manufacturing: Heat sinks, enclosures, and mounting plates

Industrial Machinery: Pump housings, valve components, and machinery parts

Robotics and Automation: Precision frames, joints, and movement mechanisms

Technical Specifications

Tolerance Range: From ±0.005mm for critical dimensions

Surface Finish: Capable of achieving 0.4μm Ra without secondary operations

Maximum Part Size: 1000×800×500mm machining capacity

Production Volume: Prototype to high-volume production capabilities

By leveraging our A6061 Aluminum Mechanical Parts CNC Machining Service, manufacturers gain access to precision components that enhance product performance while reducing total cost of ownership. Our expertise in both casting applications and precision machining ensures seamless integration of A6061 aluminum parts into your production workflow, delivering reliable solutions for the most demanding industrial applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |