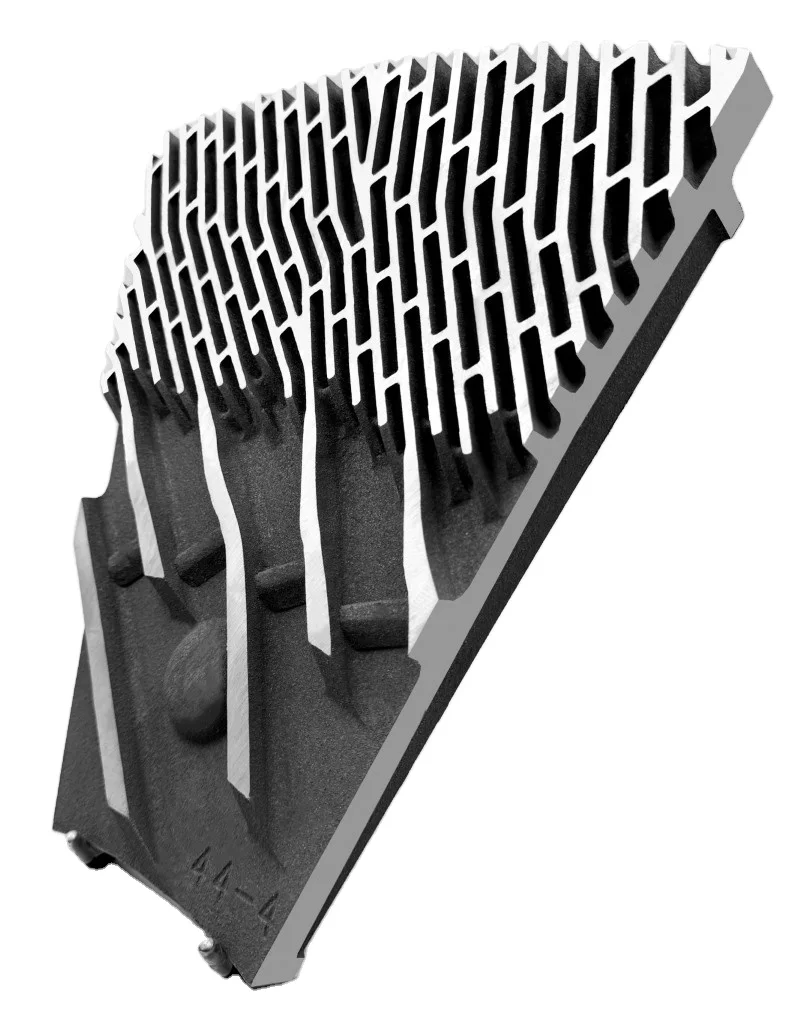

44-Inch Refiner Center Plate Grinding Disc for MDF Refiner Mill Premium Casting Services Product

- Overview

- Recommended Products

In the high-volume production of Medium-Density Fiberboard (MDF), the refiner mill is the heart of the process, defining fiber quality and overall plant efficiency. The 44-Inch Refiner Center Plate Grinding Disc is a critical wear component in this demanding application. Our premium casting service specializes in manufacturing these large-scale discs to the highest standards, delivering superior wear life, operational consistency, and cost-effectiveness for your continuous production line.

Premium Material for Extreme Abrasive Service

We engineer our center plates from specialized high-chromium white iron alloys and nickel-chrome hard irons. These materials are specifically formulated to withstand the exceptionally abrasive nature of wood lignins and mineral contaminants present in MDF stock. The high carbide volume fraction in these alloys provides an extreme level of surface hardness, directly translating to dramatically extended service intervals. This robust material composition also resists the mechanical impacts and high-temperature fluctuations inherent in the refining process, ensuring structural integrity over the long term.

Precision-Controlled Production for Optimal Performance

The manufacturing of a 44-inch disc demands advanced foundry and machining capabilities. We employ a controlled resin sand casting process to achieve a sound, defect-free casting with a uniform metallurgical structure. Following casting, a critical heat treatment (austenitizing and tempering) optimizes the microstructure, maximizing hardness and toughness. The final precision is achieved through large-scale CNC machining and surface grinding. This ensures the disc's exact flatness, precise mounting hole alignment, and the accurate geometry of the refining patterns (bars and grooves), which is essential for optimal fiber fibrillation and consistent steam flow.

Critical Application in MDF Fiber Preparation

This 44-Inch Center Plate is a direct-fit component for major refiner mills used in MDF plants worldwide. Its primary function is to work in conjunction with the counter plate to defiberize wood chips under high pressure and temperature, creating the fine, uniform fibers required for high-quality board. A precisely manufactured and balanced disc ensures stable operation, minimizes vibration, and provides consistent refining action. This leads to superior fiber quality, reduced energy consumption per ton of output, and maximized uptime between scheduled maintenance.

Choose our premium casting service for your refiner center plates. We provide the material science expertise, precision manufacturing, and rigorous quality control needed to enhance the productivity and profitability of your MDF refining line.

Product name: |

Grind segment |

Specification: |

14-16",17-18",20-24",26-30",42-48",52-58",CC450 |

Material: |

Nickel hard alloy Steel |

Usage: |

Inox Stainless Steel Metal |

Color: |

Natural |

Shape: |

Customized Shape |

Feature: |

Durable |

MOQ: |

1 Piece |

Warranty |

3 years |

ANDRITZ, a key player in the MDF and pulp and paper industry, manufacture it’s famous pressurized refining systems. The ANDRITZ single-disc refiners, equipped with the signature swing door design, enhance efficiency for plate changing process. Their comprehensive solution covers everything from debarking and chipping to screening, washing, and refining.

Q1. What is the advantage about your company? |

||||||||

A1. Our company has professional team and professional production line. |

||||||||

Q2. Why should I choose your products? |

||||||||

A2. Our products are high quality and low price. |

||||||||

Q3. The logo and the color can be customized? |

||||||||

A3. Yes, we welcome you to sample custom. |

||||||||

Q4. Any other good service your company can provide? |

||||||||

A4. Yes,we can provide good after-sale and fast delivery. |

||||||||