- סקירה

- מוצרים מומלצים

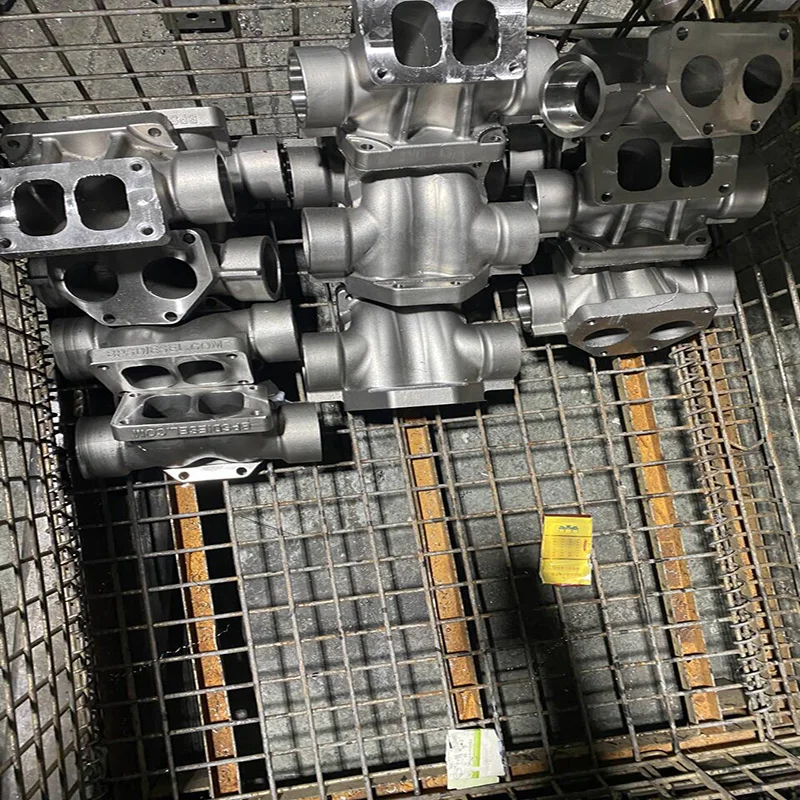

בתחום הקריטי של מערכות נוזלים תעשייתיות, גוף המשאבה משמש כגבול לחץ עיקרי וכשדרה המבנית. השירותים שלנו בתחום היציקה באיכות גבוהה מספקים גופי משאבה מפלדה בעלי יצוקת חול לפי הזמנת OEM, אשר תוכננו כדי לעמוד בלחצים קיצוניים, בתווכים קורוזיביים ובתנאי עבודה כבדים. אנו מספקים פתרונות מדויקים שמתאימים לדרישות החזקות של יצרני ציוד מקורי, ומבטיחים ביצועים אמינים ביישומים הקיצוניים ביותר בתחומים רבים.

Сплавי פלדה איכותיים לתנאי שרות קיצוניים

אנו משתמשים טווח מקיף של דרגות פלדה יצוקה להתאמה לצרכים תפעוליים ספציפיים:

פלדת פחמן (A216 WCB): סטנדרט התעשייה המציע תכונות מכניות מمتازות ויציבות לחץ לשירות כללי עד 425° צלזיוס

פלדה לטמפרטורות נמוכות (A352 LCB): מתכנת במיוחד לצורך שמירה על עמידות להשפעה ביישומים קריוגניים עד -46° צלזיוס

פלדת אלומון (A351 CF8/CF8M): מספקת עמידות חמצונית מתקדמת לעיבוד כימי, כאשר CF8M (316) מספק הגנה משופרת מפני כלורידים

פלדת סגסוגת (A217 WC6/WC9): דרגות כרום-몰יבדן שמאפשרות חוזק מוגבר בטמפרטורות גבוהות ועמידות משופרת בפני שחיקה ליישומי ייצור חשמל

טכנולוגיית יציקת חול מתקדמת לאיכות גבוהה

תהליך הייצור שלנו משלב בין אומנות מסורתית לטכנולוגיה מודרנית:

מערכת יציקת חול רזיני: אנו משתמשים במערכות איגוד מסוג פורן נובייק ובפנול אלקלי, שיוצרות יציקות עם דיוק ממדי יוצא דופן (CT9-11) ואיכות משטח גבוהה

סימולציה משולבת של CAE: תוכנת מודל링 מתקדמת של הקשה מבטיחה אופטימיזציה של עיצוב הזרקה ועמדות שיאוב כדי למנוע התקצרות ונקבוביות בחלקים קריטיים של הדופן

מטלורגיה מבוקרת: התכה באינדוקציה בתדר בינוני עם ניתוח ספקטרומטרי מבטיחה הרכב כימי מדויק בהתאם לדרישות ASTM

מומחיות בעיבוד תרמי: תהליכי נורמליזציה, קירור וטמפרינג מקיפים המבטיחים את התכונות המכניות הנדרשות ושיחרור מתחים שיוריים

יכולות ייצור מלאות ממוקדות על OEM

השירות שלנו מתרחב מעבר ליציקה וכולל רכיבים גמורים, מוכנים להתקנה:

עיבוד מדויק: עיבוד מלא באמצעות CNC של פנים הצינורות, מעגלי הברגים ופני החותמים תוך שמירה על סובלנות לפי ISO 2768-m

פרוטוקול הבטחת איכות: יישום שיטות בדיקה לא משמידות (NDT) כולל בדיקת חדירה נוזלית (PT) ובדיקת קרינה (RT) בהתאם לסטנדרטים של ASTM

הכנה לפני שטיפה: שפיכת גזירה ויישום ציפויים מגנים להגנה מפני קורוזיה במהלך אחסון והובלה

חבילת מסמכים: אישורי חומרים ודוחות בדיקה מלאים המאפשרים זיהוי מלא של השרשרת

יישומים תעשייתיים מאומתים

גופי המשאבות שלנו ממלאים תפקידים קריטיים בתחומים הבאים:

עיבוד כימי: טיפול בחומצות קורוזיביות, ממסים ומדחפיים מחמיצים

ייצור נפט וגז: העברה בצינורות, הזרמת מים ושירות בתрафים

ייצור חשמל: הזנת דוד, סירקולציית מעבה ומערכות קירור מים

טיהור מים: מתקני RO (היפוך אוסמוטי) בעלות לחץ גבוהה ומתקני התפלה

שדרגו איתנו במפרך לייצור גופי משאבות שמגדירים מחדש את עמידות והדיוק. הגישה שלנו, המיועדת יצרני ציוד מקורי (OEM), בתחום יציקת חול מותאמת מבטיחה רכיבים העונים על דרישות הקשות של מערכות טיפול בנוזלים מודרניות ואף עולה עליהן, ומביאה אמינות ואורך חיים בלתי מתחרים ביישומים קריטיים.

השירותים שלנו |

חיתוך מדויק CNC, מסתובב מדויק CNC פרוטוטיפינג מהיר תבנית הזרקת פלסטיק דכיסת מתכת, יציקת מolds מold סיליקון וgom, הרכבה של אלומיניום, ייצור מolds, וכו' |

חומר |

אלומיניום סגסוגת: 5052/6061/6063/7075 וכו' סיג סגסוגת: 3602/2604/h59/h62/וכו' פלדה נקיה סגסוגת: 303/304/316/412/וכו' סגסוגת פלדה: פחמן/פלדת מודעות/וכו' חומרים חומרים מיוחדים: לוקסיט/נילון/בקליט/וכו' פלסטלסטיק, עץ, סיליקון, גומי, או לפי דרישות הלקוח |

טיפול שטח |

אנודה, שפיכת חול, ציור, כיסוי אבקה, חשמל-גלאי,蠶ילק דפוס, תספורת, מברשת, פולישינג, חיתוך לייזר... |

פורמט ציור |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl, וכו' |

פרויקט שירות |

להספק שירות של תכנון פרויקט, ייצור וטכנולוגי, פיתוח ומניית מolds, וכו' |

מבחן מכונה |

מד גובה דיגיטלי, קליפר, מכונת מדידה של שלושת הקואורדינטות, מכונת הקרנה, מדד חריפות, מדד קשיחות וכן הלאה |

הבטחת איכות |

ISO9001: 2015 TUV מוסמך |

אריזה |

קופסאות קופסת עץ, או לפי דרישות הלקוח |

להעביר |

DHL, FEDEX, UPS, TNT, EMS, SF או לפי דרישות הלקוחות |