- סקירה

- מוצרים מומלצים

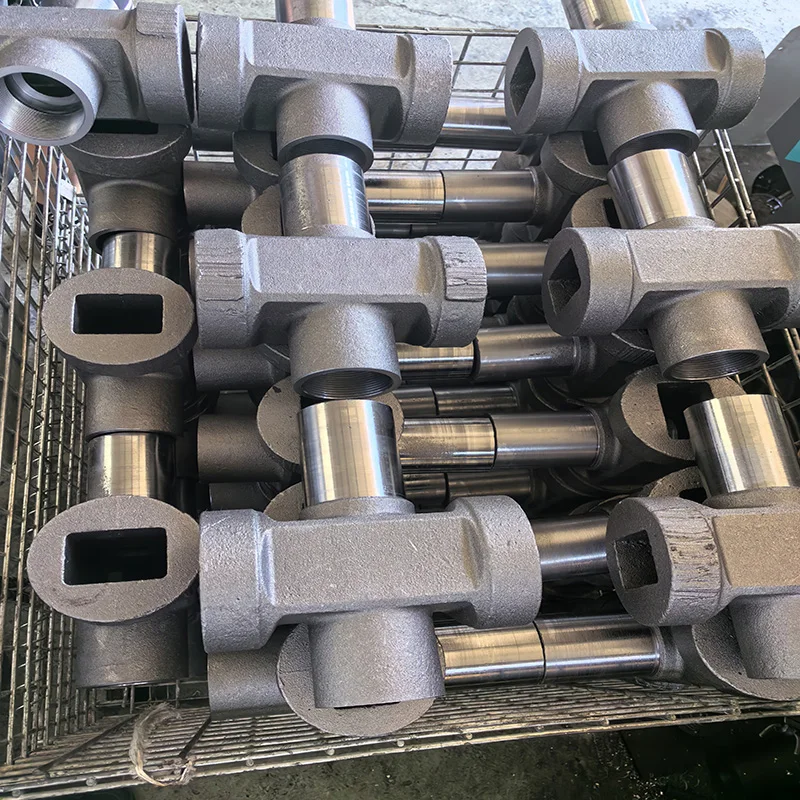

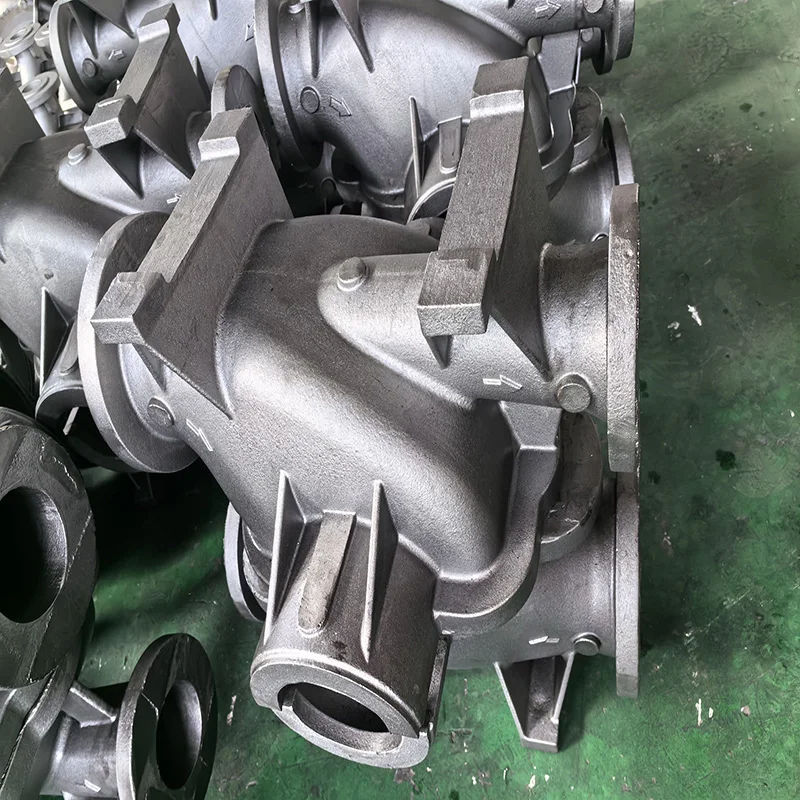

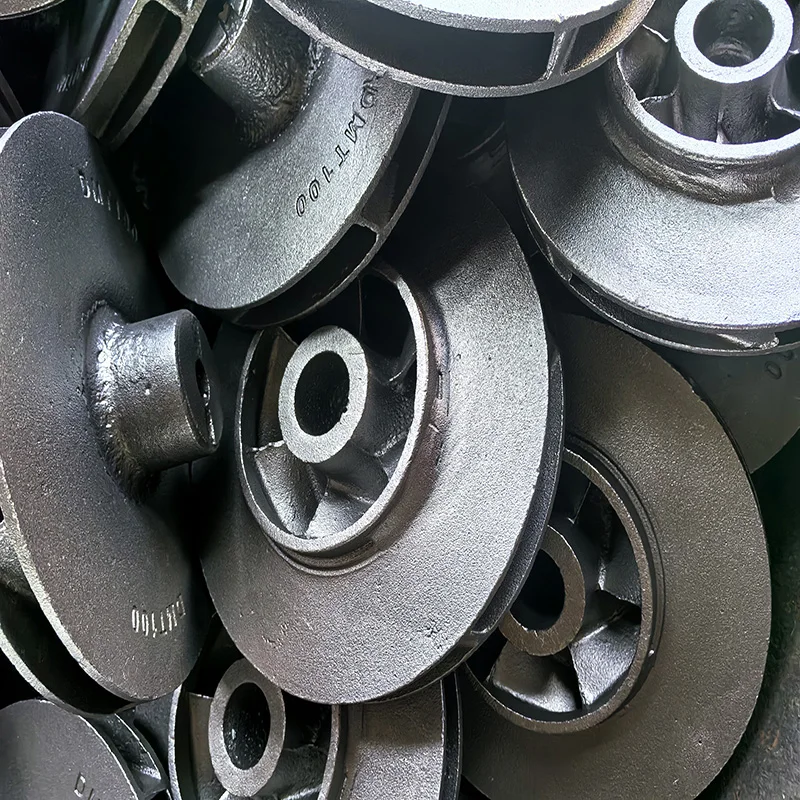

בתור יצרן מומחה בתחום הטריזים, אנו מספקים טריזים דוקטייליים מותאמים אישית באמצעות ברזל איכותי GGG40 (הידוע גם בשם EN-GJS-400-15), ומייצרים רכיבים עם תכונות מכניות יוצאות דופן ודقة ממדית גבוהה. תהליך הייצור המדויק שלנו מבטיח שכל טריז עומד בדרישות הקפדניות של התקנים הבינלאומיים, ומציע ביצועים מובילים לתחום הרכב, המכונות והבנייה ברחבי העולם.

תכונות חומר מתקדמות של ברזל דוקטיילי GGG40

ברזל דוקטיילי GGG40 מעוצב כדי לאזן אופטימלית בין חוזק ודוכנות, מה שהופך אותו למושלם ליישומים קשיחים:

חוזק מתיחה גבוה: חוזק מתיחה מינימלי של 400 MPa מבטיח ביצועים אמינים תחת עומסי עבודה כבדים

מתיחה מעולה: מתיחה מינימלית של 15% מספקת עמידות מרשימה לפגיעה וקשיחות

עמידות טובה לusz fatigue: עמיד בתנאי עומס מחזורי ללא כשל

קלות עיבוד יוצאת דופן: טובה מפלדה ומDarיגות ברזל אחרות, מקטינה את עלויות הייצור

עמידות טובה לשחיקה: שומר על יציבות ממדים תחת חיכוך ותנאים קשוחים

תהליך ייצור מתקדם ובקרת איכות

המפרך שלנו משתמש בטכנולוגיית ייצור מתקדמת:

ייצור דקיק באמצעות יציקת חול: צורב חול רזיני מבטיח דיוק ממדי בתוך דרגות סובלנות CT8-9

בקרת ספקטרומטר: ניטור בזמן אמת של הרכב הכימי מבטיח עקביות של החומר

אימוג'ון מבוקר: טיפול מתקדם במגנזיום מבטיח 80-90% אימוג'ון לצורך תכונות אופטימליות

יכולות טיפול حراري: זמינות אנילינג, נורמליזציה והסרת מתחים לפי דרישות

מפרט טכני ויכולות ייצור

טווח משקל יציקה: 1 ק"ג עד 500 ק"ג לרכיב בודד

דיוק ממדי: CT8-9 לפי תקני ISO 8062

איכות משטח: 6.3-12.5 μm Ra, גימור כפי שיצק

קיבולת ייצור שנתית: למעלה מ-3,000 טון של יציקות ברזל דاكتילי באיכות גבוהה

תעודה איכות: תהליכי ייצור עם תקן ISO 9001:2015

บริการปรับแต่งแบบครอบคลุม

הגמישות בייצור מאפשרת התאמה מלאה:

אופטימיזציה של העיצוב: תמיכה הנדסית בעיצובים ידידותיים ליציקה

ייצור תבניות: תבניות עץ, פלסטיק ומתכת לנפחי ייצור שונים

שירותי מכונה: יכולות מכונת CNC ומכונות קונבנציונליות

עיבוד פני השטח: סיעור באבן, צביעה וציפוי עמידות לאוכלוס

יישומים תעשייתיים ויתרונות ביצועים

הזרקות ברזל דוקטייל GGG40 שלנו משרתות תפקידי מפתח ב:

רכיבי רכב: כלפישרים, חלקים של מערכת התלייה וקופסאות הילוכים

מכונות תעשייתיות: גלגלות משאבות, גופי שסתומים ורכיבי תיבת הילוכים

ציוד בנייה: רכיבי הידראוליקה, חלקים מבניים וסוגריים להרכבה

מכונות חקלאיות: רכיבי מיטלטלים, חלקים לטראקטור ורכיבי קוצרות

בטיחת איכות ובדיקות

כל רכיב עובר אימות איכות מחמיר:

בדיקות מכניות: בדיקות מתיחה ומכה לפי תקנים EN 1563

ניתוח מיקרו-מבנה: הערכת דרגת הקימור של הגרפיט ומבנה המטריצה

בדיקות לא משממות: זמינות בדיקות אולטראסאונד וחלקיקים מגנטיים

בדיקת מידות: אימות באמצעות CMM לממדים קריטיים

שדרוג עם מומחיות הייצור שלנו בזרזורי ברזל דקטילי GGG40 שמשתלבים בתכונות חומר עליונות עם הנדסת דיוק. גישתנו המותאמת מבטיחה רכיבים שמציעים ביצועים, אמינות וערך אופטימליים ליישומים הדורשניים ביותר שלכם, נתמכים על ידי תמיכה טכנית מקיפה וassicuranza איכות.

חומר |

פלדה, פלדה נקיה, אלומיניום, ברזל, פלדה קARBON, נחושת, צהוב, ליגת, וכו'. |

עובי |

0.1mm עד 12mm, לפי בקשתך |

גדלים |

1) לפי תבליטי לקוחות' 2) לפי דגמי לקוחותomers |

טיפול שטח |

אנודיזציה, גלובזים, צינק, ניקל, כרום, קוטר פולימרי, ציור, וכו'. |

פורמט ציור |

DWG, DXF, STEP, STP, STL, AI, PDF, JPG, טיוטה. |

אריזה |

כיס פוליאסטר+תיבה של קרטון+מקרה עץ/פלט, לפי בקשת הלקוח |

משלוח |

1) על ידי משלוח מהיר, כמו DHL, TNT, Fedex, וכו', בדרך כלל 5-7 ימים כדי להגיע |

2) באוויר למשתל איר, בדרך כלל, 3-4 ימים כדי להגיע |

|

3) דרך נמל ים, בדרך כלל 15-30 ימים כדי להגיע |

|

זמן מסירה |

תלוי בכמויות, בדרך כלל כ-20 ימים. |

תנאי תשלום |

T/T, פאייפאל, Trade Assurance |

הסמכה |

ISO |

שירות לוגו |

מסופק |

שימוש |

משתמשים בהרבה תחומים בבנייה, תעשייה, ותעשיית רכב. |