- نظرة عامة

- المنتجات الموصى بها

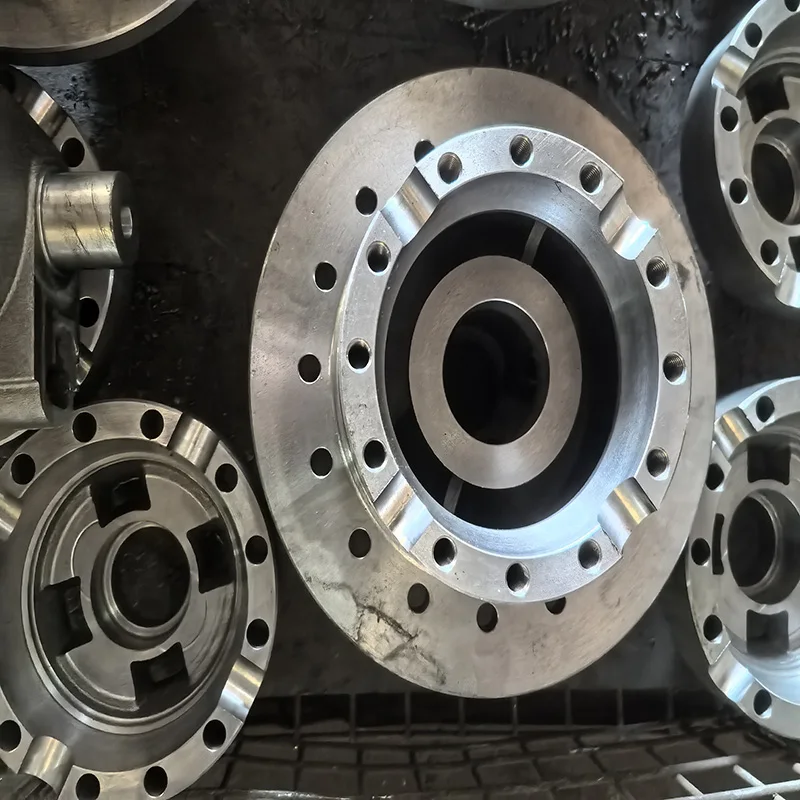

في مجال توليد الطاقة، تمثل الدرائن الدينامو عالية الكفاءة مكونات حيوية تؤثر بشكل كبير على أداء المولد وموثoniته. توفر خدمات الصب المتخصصة لدينا درائن دينامو ممتازة تُحسّن نقل الطاقة، وتقلل من فقد الطاقة، وتمدد عمر الخدمة في تطبيقات المولدات الصعبة عبر قطاعات متعددة.

اختيار المواد المتفوقة

تُصنع بكرات المولدات الدوارة لدينا باستخدام حديد رمادي عالي الجودة (HT200-HT250) وتركيبات من الحديد الدكتايل المصممة خصيصًا للتطبيقات التي تتطلب دورانًا بسرعة عالية. توفر هذه المواد قدرة استثنائية على امتصاص الاهتزازات — تبلغ تقريبًا 20 إلى 25 ضعفًا أكثر من الفولاذ — وهي أمر بالغ الأهمية للحفاظ على استقرار أنظمة التوليد. ويضمن هيكل رقائق الجرافيت المتحكم فيه في الحديد الرمادي مقاومة ممتازة للتآكل وقدرة تشحيم طبيعية، في حين يوفر الحديد الدكتايل خصائص ميكانيكية محسّنة مع قوة شد تصل إلى 120,000 رطل لكل بوصة مربعة للتطبيقات التي تتطلب مقاومة فائقة للصدمات.

بالنسبة للتطبيقات الخاصة التي تتطلب تقليل الوزن، نقدّم بكرات من سبائك الألومنيوم تحافظ على السلامة الهيكلية مع تقليل الكتلة الدورانية. تخضع جميع المواد لتحليل طيفي دقيق للتحقق من التركيب الكيميائي وضمان أداء متسق عبر دفعات الإنتاج.

عمليات التصنيع الدقيقة

تُدمج تقنيتنا المتقدمة في الصب بالرمل أنظمة أتمتة تُنتج مكونات البكرات بدقة أبعاد استثنائية وجودة سطح عالية. يستخدم هذا العملية قوالب رمل مربوطة براتنج تحافظ على تحملات دقيقة مع تقليل العيوب مثل احتباس الرمل والمسامية الناتجة عن الغازات.

نستخدم محاكاة الحاسوب للصب لتحسين عملية التصلب والقضاء على العيوب المحتملة قبل بدء الإنتاج. يضمن هذا الأسلوب الاستباقي توزيعًا موحدًا للمواد ويعزز الخصائص الميكانيكية للبكرات المنتهية. وتقوم عمليات التشغيل الدقيقة اللاحقة بتحسين الأسطح الحرجة وأبعاد الثقوب لتحقيق تركيز دقيق ضمن حدود 0.001 بوصة، مما يضمن محاذاة مثالية في أنظمة ناقل المولد.

تحسين خصائص الأداء

توفر بكرات الدينامو المصنعة من خلال عملياتنا المُحسّنة فوائد تشغيلية استثنائية:

خصائص توازن متفوقة: يتيح التوازن الساكن والديناميكي الدقيق تشغيلًا سلسًا عند السرعات الدورانية التي تزيد عن 3500 دورة في الدقيقة، مما يقلل الاهتزازات في أنظمة المولدات

م profiles مُحسّنة: تضمن الأخاديد المصممة بدقة تلامسًا أقصى مع الحزام وكفاءة عالية في نقل القوة، مع تقليل الانزلاق إلى أقل من 2%

مقاومة ممتازة للتآكل: تحافظ البنية المعدنية الخاضعة للرقابة على سلامة الأخاديد خلال فترات الخدمة الطويلة، حتى في التطبيقات ذات الدورات العالية

متطلبات صيانة مخفضة: تقلل الصب عالي الجودة والمعالجات السطحية الخاصة من التآكل وتمدد فترات الصيانة

مقاومة تآكل محسّنة: توفر المعالجات السطحية الاختيارية حماية في الظروف البيئية الصعبة

ضمان الجودة والشهادة

تشمل عمليات التصنيع لدينا بروتوكولات جودة شاملة:

التحقق من الأبعاد: فحص جميع الخصائص والتسامحات الحرجة باستخدام جهاز قياس الإحداثيات (CMM)

الاختبار غير التدميري: كشف العيوب تحت السطحية والسطحية باستخدام الفحص بالموجات فوق الصوتية والجسيمات المغناطيسية

شهادة المواد: التحقق من التركيب الكيميائي والخصائص الميكانيكية وفقًا للمعايير الدولية

التحقق من الأداء: اختبار التوازن الدوراني وتشغيل دورة تشغيل مُحاكاة

التوثيق: إمكانية التتبع الكاملة من المادة الخام إلى المكون النهائي

حلول تطبيقات متقدمة

تؤدي بكرات الدينامو عالية الكفاءة لدينا وظائف حيوية في أنواع مختلفة من المولدات:

أنظمة الطاقة الاحتياطية

مولدات احتياطية تجارية تتطلب تشغيلاً موثوقاً وانتقال طاقة سلساً

أنظمة طوارئ كهربائية تتطلب عملاً خالياً من الأعطال خلال المواقف الحرجة

وحدات احتياطية صناعية تحتاج إلى متانة عند تطبيق أحمال مفاجئة

تطبيقات الطاقة الأساسية

مولدات البناء العاملة في بيئات عالية الاهتزاز مع دورات عمل مستمرة

أنظمة الطاقة البحرية التي تتطلب مقاومة للتآكل وموثوقية في الأجواء المالحة

وحدات الطاقة عن بُعد حيث يكون الوصول للصيانة محدودًا والموثوقية أمرًا بالغ الأهمية

حلول الطاقة الهجينة

أنظمة المولدات المتكاملة للتشغيل والإشعال في تطبيقات الطاقة الهجينة الحديثة

أنظمة BSG (مولد بدء التشغيل بالحزام) في التكوينات الهجينة الخفيفة التي تتطلب خصائص ديناميكية دقيقة

القدرات على التخصيص التقني

نقدم دعمًا هندسيًا شاملاً لتطبيقات المولدات الخاصة:

تحليل التطبيق: تقييم متطلبات التشغيل لاقتراح تكوين البكرة الأمثل

تحسين التصميم بمساعدة الحاسوب (CAD): تحسين تصميم البكرة لتعزيز الأداء وكفاءة التصنيع

تطوير النموذج الأولي: تسريع التحقق من المنتج من خلال أخذ العينات واختبارها بسرعة

توسيع الإنتاج: دعم المتطلبات من الصغيرة

خدماتنا |

تصنيع باستخدام الحاسب الآلي CNC لآلات الطحن الدقيق، تصنيع باستخدام الحاسب الآلي CNC للتحويل الدقيق، تصنيع النماذج الأولية السريعة القالب المحقن البلاستيكي تشكيل المعادن، الصب بالمolds قوالب السيليكون والمطاط، التشطيب الألمنيوم، تصنيع القوالب، إلخ |

المادة |

سبائك الألمنيوم: 5052/6061/6063/7075 إلخ سبائك النحاس: 3602/2604/h59/h62/إلخ سبائك الفولاذ المقاوم للصدأ: 303/304/316/412/إلخ سبائك الصلب: الكربون/صلب القوالب/خ. مواد خاصة أخرى: لوسايت/نيلون/باكيت/خ. بلاستيك، خشب، سيليكون، مطاط، أو وفقًا لمتطلبات العملاء |

المعالجة السطحية |

التشطيب الأنودي، الرش بالرمل، الطلاء، الطلاء المسحوق، الكهربة، الحرير الطباعة، الفرشاة، التلميع، النقش بالليزر... |

صيغة الرسم |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl، إلخ |

مشروع خدمة |

لتقديم تصميم المشروع، والإنتاج والخدمات الفنية، وتطوير القوالب وتصنيعها، وما إلى ذلك |

آلة الاختبار |

مقياس الارتفاع الرقمي، الميكrometer، آلة قياس الإحداثيات الثلاثية، جهاز القياس بالبروجكتر، جهاز قياس السطحية، جهاز قياس الصلابة وغيرها |

ضمان الجودة |

حاصلة على شهادة ISO9001:2015 من TUV |

التغليف |

رغوة، كرتون، صناديق خشبية، أو حسب متطلبات العميل |

توصيل |

DHL، FEDEX، UPS، TNT، EMS، SF أو وفقًا لمتطلبات العملاء |