- Overview

- Recommended Products

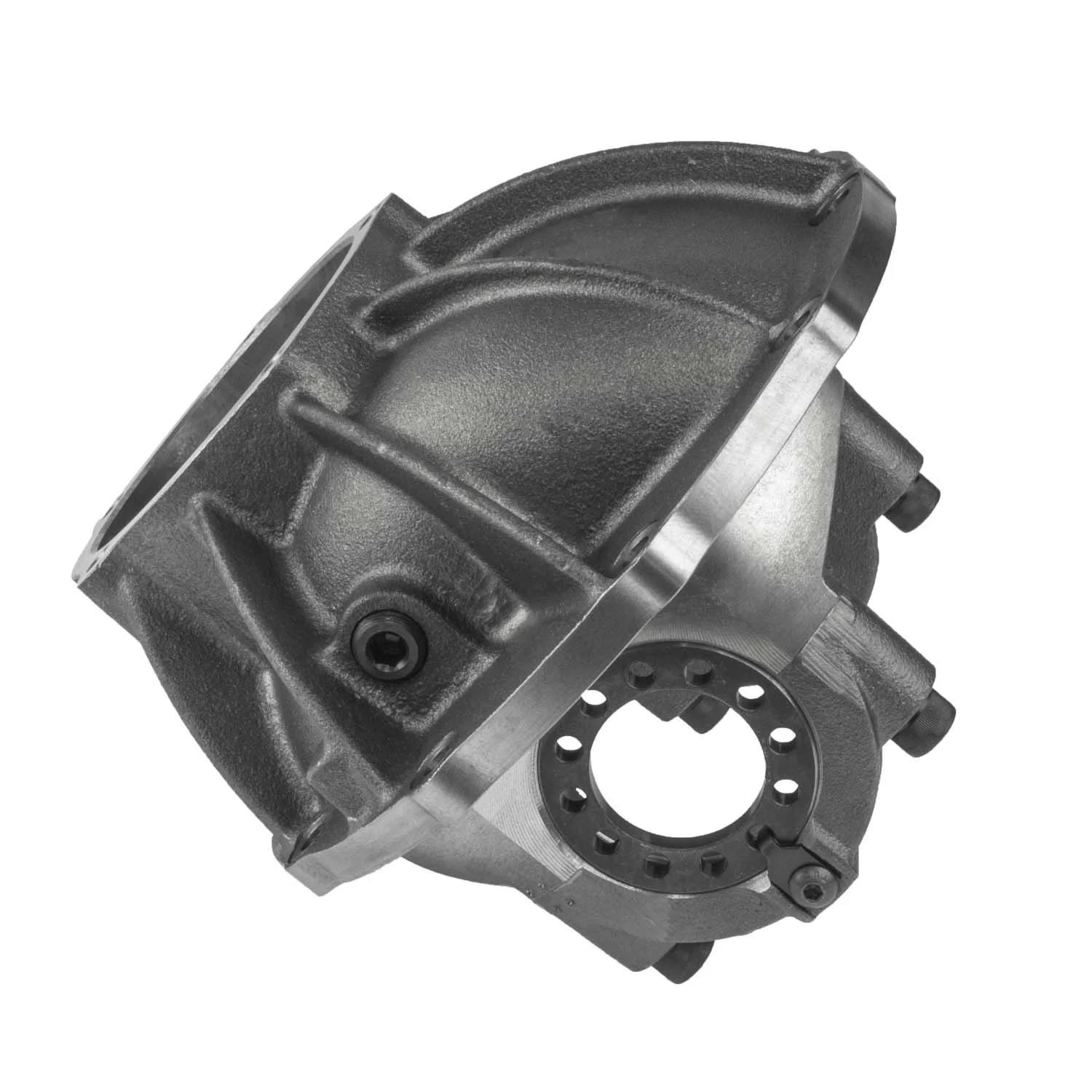

As a specialized nodular differential housing castings factory, we deliver precision-engineered casting solutions for automotive and heavy-duty applications. Our differential housing castings provide the perfect balance of strength, durability, and weight optimization for demanding operating conditions.

Material Excellence

Our castings utilize high-grade nodular iron (ductile iron) EN-GJS-400-18, EN-GJS-500-7, and EN-GJS-600-3, characterized by:

Superior tensile strength (400-600 MPa)

Excellent elongation properties (18-3%)

Outstanding impact resistance

Enhanced fatigue strength

The unique spherical graphite structure within the ferritic or pearlitic matrix gives nodular iron its exceptional mechanical properties, combining the durability of cast iron with the flexibility of steel.

Advanced Production Technology

We employ state-of-the-art manufacturing processes:

Automated molding lines using green sand and resin sand technologies

Precision pattern making with CNC machining

Controlled melting in medium frequency induction furnaces

Inoculation and magnesium treatment for perfect nodularization

Advanced heat treatment processes (annealing, normalizing, quenching)

Performance Advantages

Our nodular differential housing castings offer:

Excellent vibration damping capacity

Superior wear resistance for extended service life

High strength-to-weight ratio

Good machinability for secondary processing

Reliable performance under extreme torque conditions

Quality Assurance

Every casting undergoes rigorous quality control:

Spectrochemical analysis for material verification

Ultrasonic testing for internal integrity

Dimensional inspection using CMM

Microstructure examination for nodularity rating

Pressure testing for leak-proof performance

Industry Applications

Our differential housing castings serve:

Automotive differential systems

Commercial vehicle axles

Agricultural machinery

Construction equipment

Mining and off-road vehicles

With comprehensive casting capabilities and strict quality management, we ensure every differential housing meets OEM specifications and performance requirements. Our technical expertise and manufacturing excellence make us the preferred partner for critical automotive components worldwide.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |