- Overview

- Recommended Products

In the demanding marine industry, where saltwater corrosion relentlessly attacks metal components, Monel 400 stands as a superior material solution. CNC-machined flange components made from this nickel-copper alloy offer exceptional longevity and reliability, making them a critical choice for engineers prioritizing system integrity and reduced maintenance in seawater applications.

Material Composition and Key Properties

Monel 400 (UNS N04400) is a solid-solution alloy primarily composed of 63-67% nickel and 28-34% copper, with small additions of iron and manganese. This composition is the foundation of its outstanding performance. Unlike many stainless steels, Monel 400 exhibits exceptional resistance to fast-flowing seawater and brine, showing a remarkably low corrosion rate of less than 0.025 mm per year. It is highly resistant to chloride-induced stress corrosion cracking and pitting, common failure points in marine environments. Furthermore, it maintains excellent mechanical properties from sub-zero temperatures up to about 480°C, with a typical tensile strength of 550 MPa and yield strength of 240 MPa.

Precision Manufacturing Process

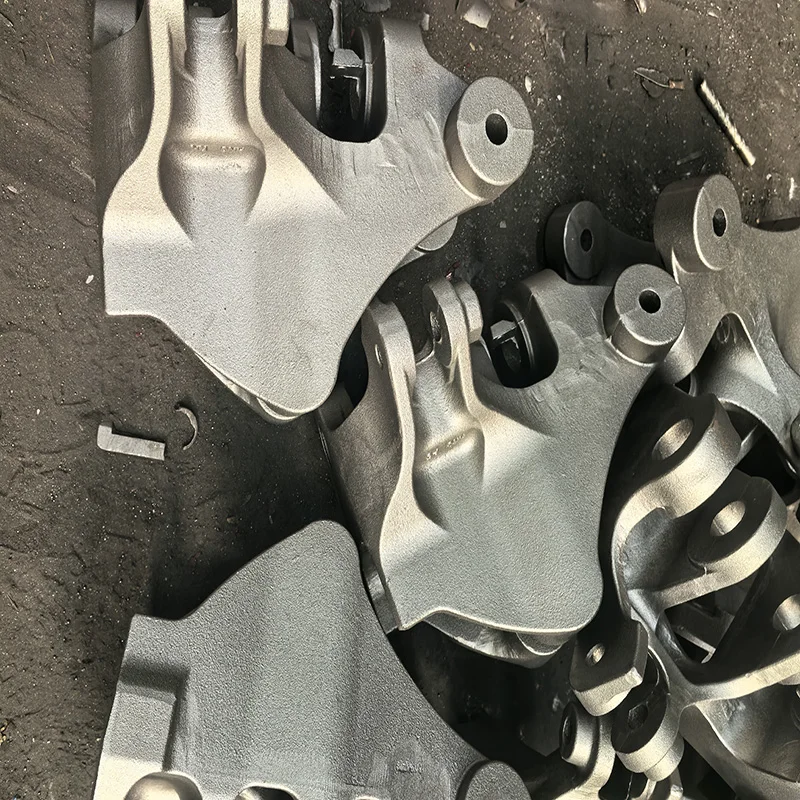

The production of these high-performance flanges involves advanced manufacturing techniques. The process begins with high-quality Monel 400 bar stock or forgings. CNC (Computer Numerical Control) machining is then employed to achieve precise dimensional accuracy and complex geometries according to international standards like ASME B16.5. This precision machining ensures perfect sealing surfaces, correct bolt hole alignment, and optimal wall thickness. The process often includes controlled heat treatment to relieve internal stresses and enhance the material's inherent corrosion resistance, followed by rigorous quality checks and non-destructive testing.

Marine Applications

Monel 400 CNC flanges are indispensable in critical marine systems. They are widely used in:

Seawater cooling and firewater systems

Desalination plant piping and brine heaters

Propeller shafts, pump shafts, and valve stems

Offshore platform piping and subsea components

Marine fasteners and fittings

Their non-magnetic properties also make them suitable for specialized naval vessels where magnetic signature is a concern.

For engineers and procurement specialists, selecting Monel 400 CNC flange components is a strategic decision for ensuring durability, safety, and cost-effectiveness in combating marine corrosion, ultimately extending service life and minimizing operational downtime.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |