- Overview

- Recommended Products

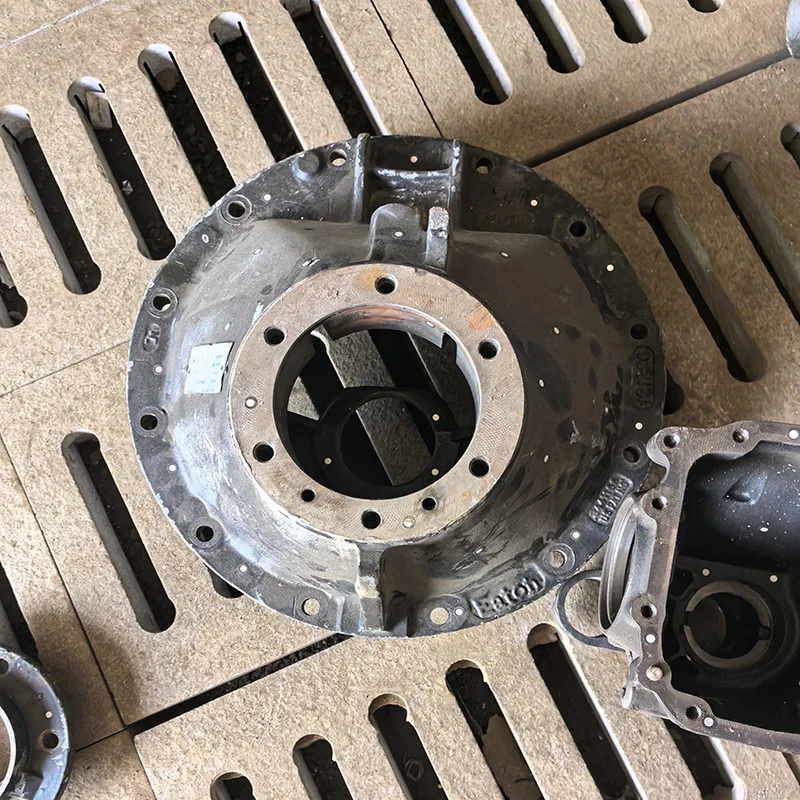

In industrial pumping systems, the impeller serves as the very heart that determines overall efficiency, reliability, and service life. Our high-quality cast iron impellers, manufactured through premium casting services, are engineered to meet the rigorous demands of various applications, providing the perfect balance of performance, durability, and cost-effectiveness.

Superior Material Selection

We utilize advanced cast iron materials to ensure optimal performance in diverse operating conditions. Our primary materials include gray iron (GG25) for excellent damping capacity and machinability, and ductile iron (GGG40/50) for enhanced strength, impact resistance, and fatigue performance. For severely abrasive applications, we offer high-chromium cast iron impellers that deliver exceptional wear resistance, significantly outperforming standard materials in challenging environments involving solid-laden fluids and corrosive media.

Precision Engineering and Manufacturing

Our manufacturing process combines state-of-the-art technology with rigorous quality control:

Pattern Making: We create precision patterns using CNC machining and 3D printing technology

Molding Process: Employing resin sand casting and shell molding techniques for superior dimensional accuracy

Quality Assurance: Implementing spectral analysis, radiographic testing, and dimensional inspection

CNC Machining: Delivering tight tolerances on critical dimensions and perfect balance

Performance Characteristics

Our cast iron impellers demonstrate:

Excellent erosion and corrosion resistance

Optimal hydraulic efficiency through precision-molded vane profiles

Superior mechanical properties maintaining stability under high rotational speeds

Reduced maintenance requirements and extended service life

Applications

Our impellers serve across multiple industries including water treatment plants, chemical processing, irrigation systems, mining operations, and marine applications. They are compatible with various pump types such as centrifugal pumps, slurry pumps, and circulation pumps.

Partner with us for comprehensive casting solutions that combine material expertise, advanced manufacturing capabilities, and stringent quality standards. We provide custom engineering support and reliable delivery schedules to meet your specific requirements.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |