- Overview

- Recommended Products

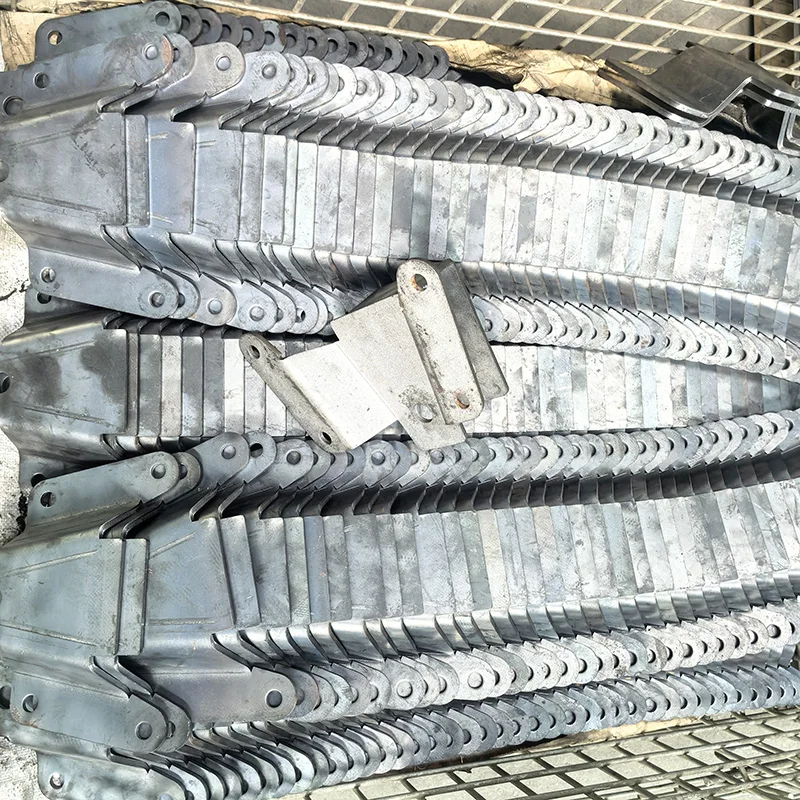

In today's competitive industrial landscape, access to reliable custom metal stamping services is crucial for product development and manufacturing success. Our comprehensive OEM and ODM capabilities deliver high-precision metal stamping parts engineered to meet exact specifications for various industrial applications. We partner with manufacturers across multiple sectors to provide customized solutions that combine advanced stamping technology with rigorous quality control, ensuring components that deliver consistent performance and reliability.

Material Versatility and Performance Characteristics

We work with a wide range of metallic materials including carbon steel (SPCC, SECC), stainless steel (304, 316), aluminum alloys (5052, 6061), and copper alloys (C11000, C26000). Our carbon steel components offer tensile strength ranging from 270-420 MPa with excellent formability, while stainless steel parts provide superior corrosion resistance with tensile strength reaching 520 MPa. Aluminum stampings deliver optimal strength-to-weight ratios with natural corrosion resistance, and copper components offer excellent electrical conductivity. All materials maintain consistent mechanical properties throughout production runs, with optional surface treatments further enhancing performance characteristics for specific operating environments.

Advanced Stamping and Manufacturing Process

Our manufacturing facilities operate high-speed precision stamping presses ranging from 25 to 500 tons, equipped with progressive and transfer die capabilities. The process begins with comprehensive DFM analysis to optimize designs for manufacturability and cost efficiency. We utilize advanced tooling systems manufactured from premium die steels (D2, SKD11) that maintain dimensional stability through production runs exceeding millions of cycles. Our integrated approach includes in-house tooling design and fabrication, supported by CNC machining centers that achieve tooling tolerances within ±0.003mm. Automated optical inspection systems monitor dimensional accuracy throughout production, maintaining part tolerances within ±0.05mm for critical features.

Comprehensive Industrial Applications

Our precision stamping services support diverse industrial sectors with components for automotive systems (bracket assemblies, electrical contacts), electronics (connector terminals, shielding components), appliance manufacturing (structural supports, thermal management parts), and industrial equipment (motor laminations, precision springs). The medical device industry utilizes our stampings for surgical instrument components and equipment housings, while the renewable energy sector specifies our parts for solar panel frames and power distribution components. Our ODM services extend to complete product development, from conceptual design to finished assembly, providing turnkey solutions for specialized applications.

Partner with our manufacturing expertise for metal stamping solutions that balance precision, quality, and cost-effectiveness. Our integrated OEM and ODM services ensure seamless transition from prototype to production, delivering components that enhance product performance, reduce assembly requirements, and provide reliable service across diverse industrial applications, supported by comprehensive quality documentation and engineering support.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |