- Overview

- Recommended Products

Elevate your Jeep's performance and durability with our specialized Custom Jeep Separator Shell Release Casting Service. Designed for off-road enthusiasts, aftermarket parts manufacturers, and restoration specialists, this service provides a high-strength, precision-engineered solution for critical drivetrain components. Whether for a custom axle build, a heavy-duty upgrade, or a vehicle enhancement project, our casting service delivers a superior foundation for improved capability and reliability.

Premium Material for Demanding Environments

Our separator shells are cast from high-grade aluminum alloys, such as A356-T6, chosen for their optimal strength-to-weight ratio and excellent corrosion resistance. The T6 heat treatment process enhances the material's mechanical properties, achieving a typical tensile strength of over 40,000 psi and significant yield strength. This ensures the component can withstand the extreme torsional stresses, shock loads, and vibrational forces encountered during aggressive rock crawling, dune running, and overlanding, all while saving unsprung weight.

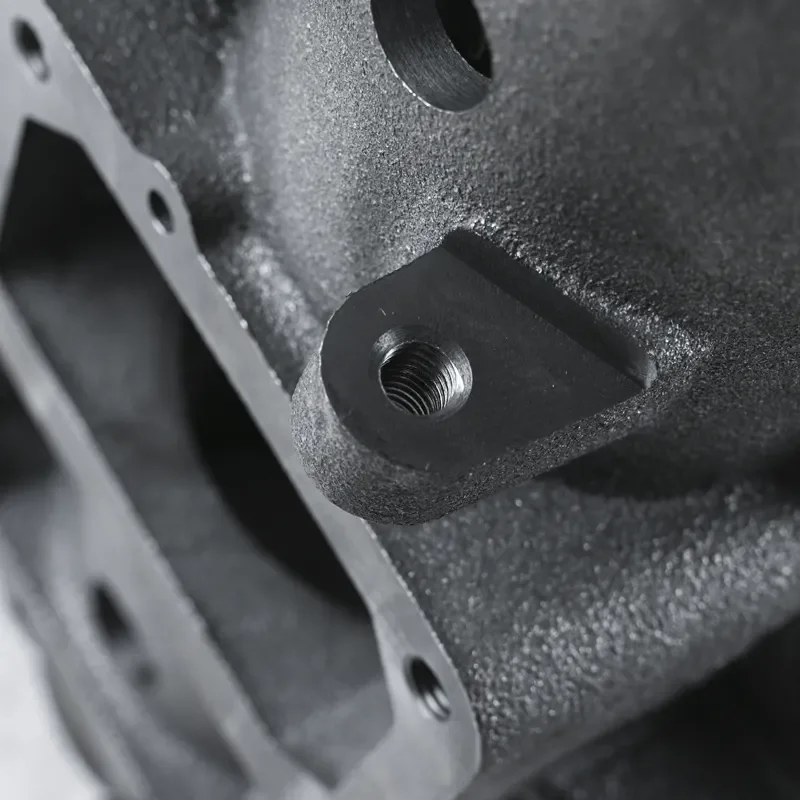

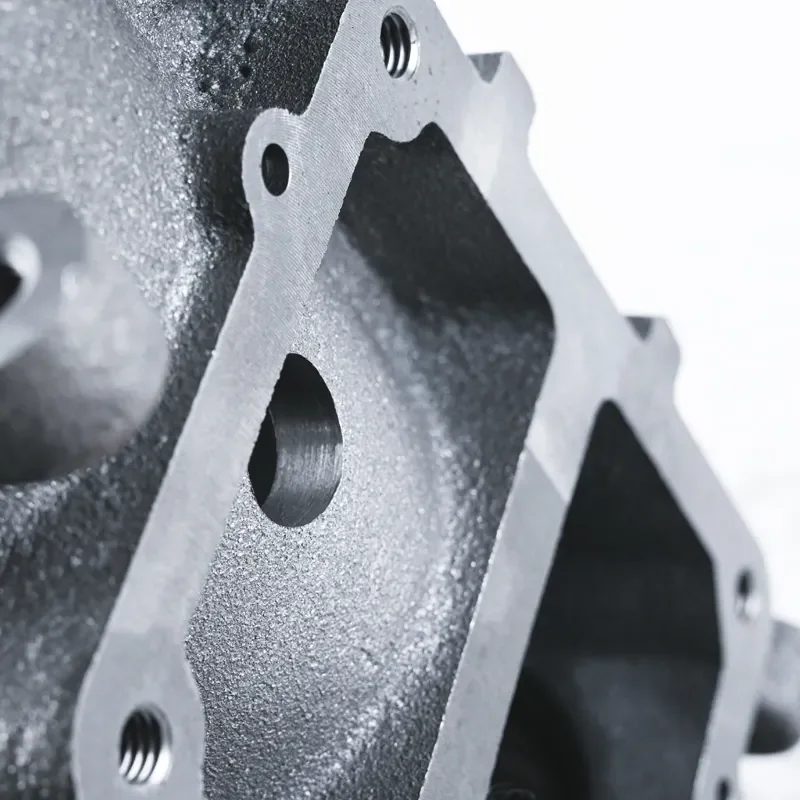

Precision Casting and Manufacturing Process

We utilize the advanced sand casting method to produce these complex components. This process allows for exceptional design flexibility to create intricate geometries, internal passages, and custom mounting features that are often impossible with other manufacturing techniques. Each shell is created from a precision-machined mold, ensuring consistent wall thickness and dimensional accuracy. Post-casting, critical surfaces, including bearing journals and sealing surfaces, are finished on CNC machining centers to exacting tolerances, guaranteeing a perfect fit with your differential carrier, axle housing, and aftermarket locker or limited-slip unit.

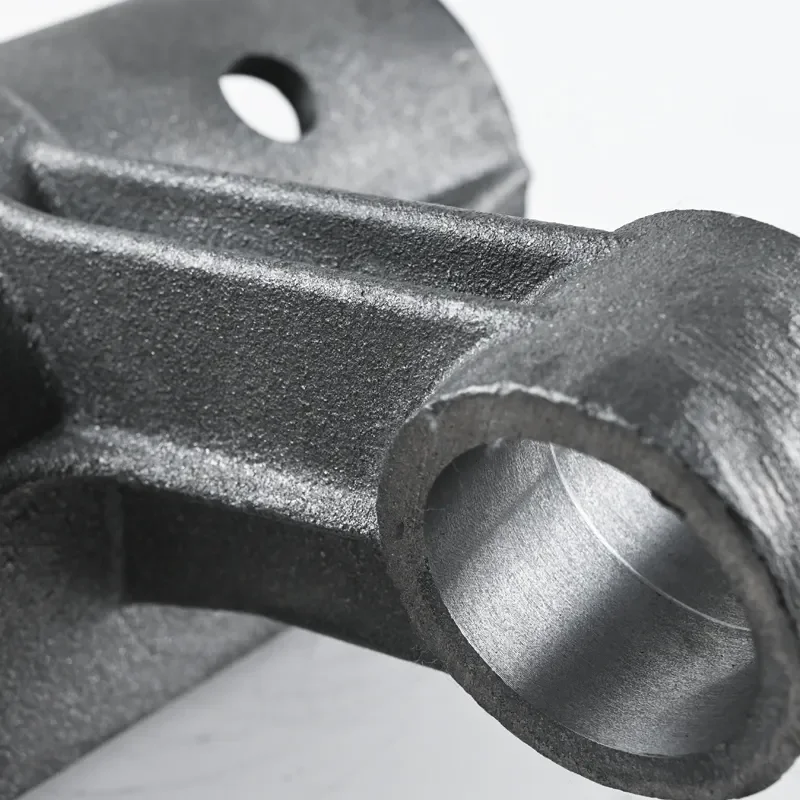

Performance and Application for Vehicle Enhancement

The separator shell is a fundamental component in many differential assemblies, responsible for housing the spider gears and facilitating smooth power distribution. Our custom service allows for enhancements over stock designs, such as increased wall thickness in high-stress areas or modified spline counts. This makes our casting ideal for Jeep owners undertaking gear ratio changes, installing aftermarket locking differentials, or rebuilding a worn axle assembly on Wrangler (TJ, JK, JL), Gladiator, and Cherokee (XJ) platforms. It provides the robust, custom-tailored core needed for a reliable and high-performing drivetrain build.

Invest in a custom-cast foundation for your next Jeep enhancement. Our Separator Shell Release Casting Service delivers the OEM-quality precision and aftermarket strength required to push your vehicle's capabilities further, with the reliability that instills confidence on any terrain.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |