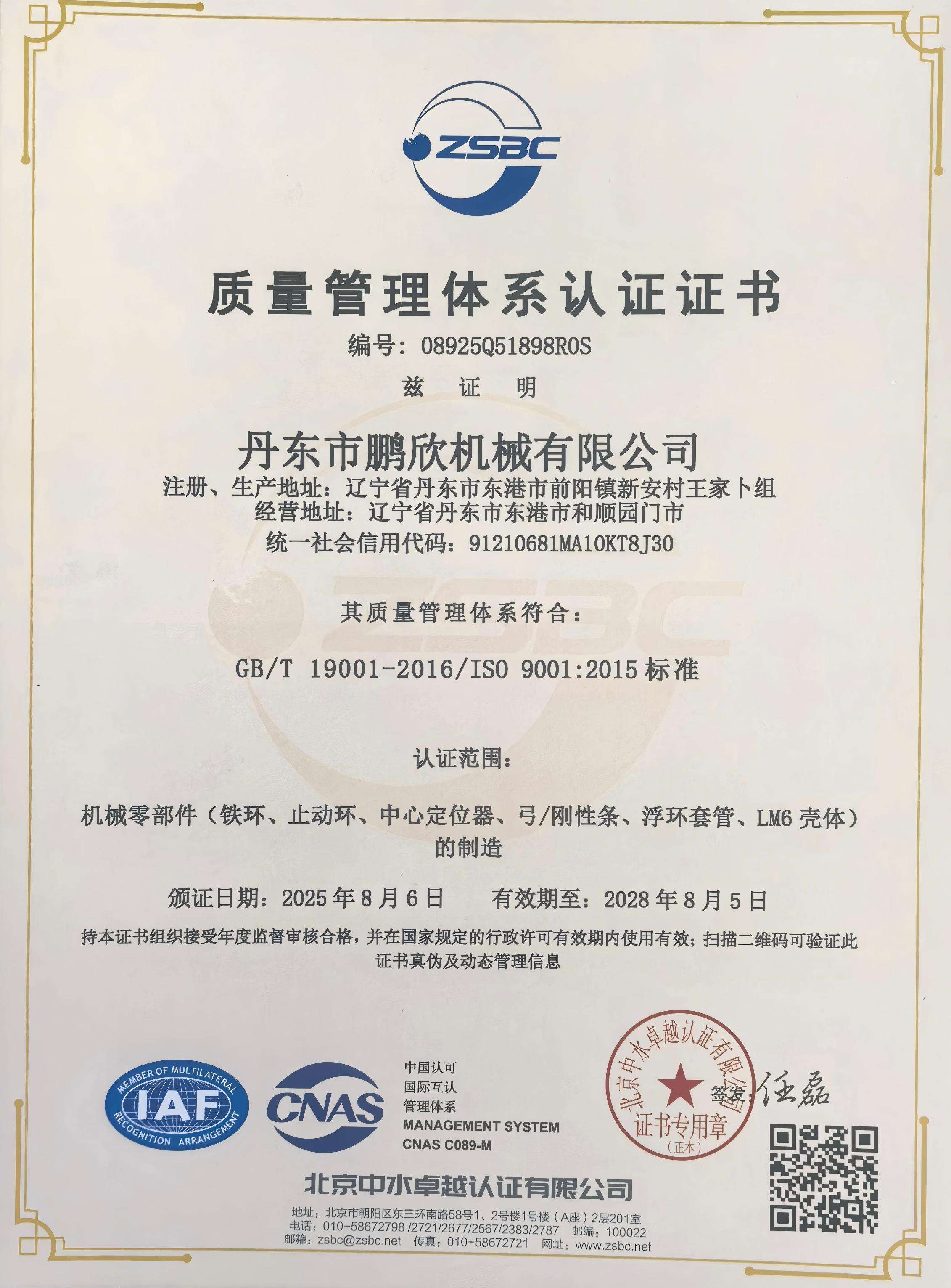

डैंडोंग पेंगशिन मशीनरी कंपनी, लिमिटेड, 1958 में स्थापित, एक निजी उद्यम है जो ढालने, मशीनिंग और सभी यूनिट के सभी अवयवों के सभी यूनिट के सभी अवयवों को विशेषज्ञता से बनाता है। 66,000 म² के साथ फैला हुआ 40,000 म² के कारखानों के साथ, इसके पास $40M के संपत्ति हैं और 330 कर्मचारी , जिसमें 46 तकनीकी कर्मचारी शामिल हैं । वार्षिक क्षमता 100,000 टन तक पहुँच जाती है।

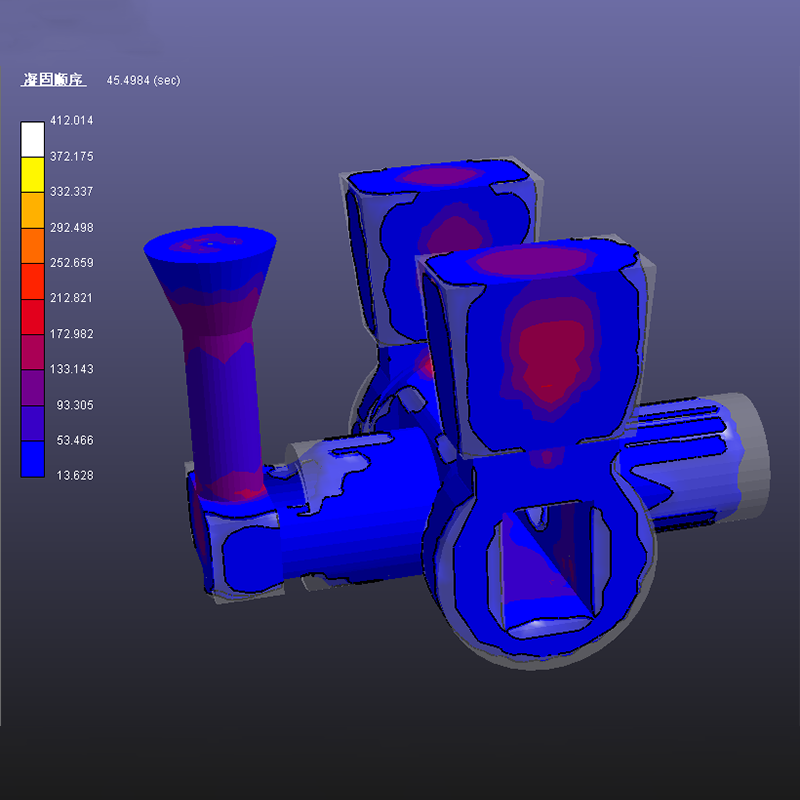

उच्च-दबाव मोल्डिंग और जापानी FBO Ⅲ उत्पादन लाइन जैसी अग्रणी प्रौद्योगिकियों के साथ सुसज्जित है, यह वर्ष में 30,000 टन तक उत्पादन करता है। सुविधाएँ 12-पल्स इलेक्ट्रॉनिक क्लोज़, CNC मशीनों, और गुणवत्ता जाँच केंद्र जिसमें नियमित यंत्र होते हैं, शामिल हैं।

80+ देशों और क्षेत्रों में बेचा जाता है, जैसे जॉन डियर, मर्सिडीज-बेंज़, जॉन डियर, और वेयर जैसी बड़ी कंपनियों की सेवा करता है, पेंगसिन विशेष रूप से गुणवत्ता, सेवा औरanggan की संतुष्टि पर ध्यान देते हुए साझेदारी का स्वागत करता है।