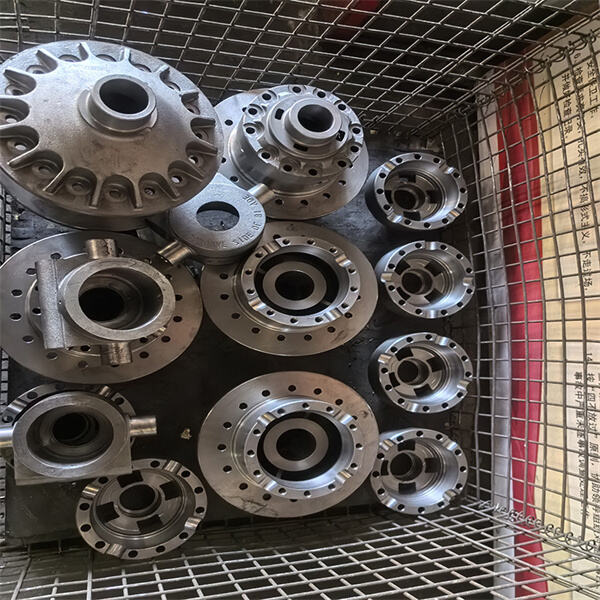

The material selection for mechanical parts is crucial. One is high-silicon molybdenum ductile iron. This special iron is strong and can take a lot of abuse, so it’s ideal for machines and tools. If you want to get the maximum speed from these mechanical parts, it is important to go with the most suitable high-silicon molybdenum ductile iron. With knowledge of the properties, benefits and where to find good suppliers, you can confidently make the right decision. At Pengxin, we’re dedicated to offering high-quality materials for all your industrial needs and being knowledgeable about high-silicon molybdenum ductile iron plays into that.

How To Select The Purpose High Silicon Molybdenum Ductile Iron For Best Mechanical Properties

Consider the properties when you choose high silicon molybdenum ductile iron. This type of iron contains a lot of silicon, which makes it resistant to wear and tear. It’s also quite tough, meaning that it can put up with a good bit of pressure without breaking. For instance, if you are producing parts for a car engine, you need something that can withstand the heat and stress of driving. The high silicon content helps with that. You should also consider the quantities of molybdenum used in the iron. Strength is added by molybdenum and the iron's tolerance for heat is enhanced. It’s putting extra armor on your material.

Also, see how the iron is farmed. It’s how it is made that determines its ultimate strength and durability. Your supplier’s process can also affect the quality, ask them how they do it. Finally, consider how the iron will be used. If for heavy machinery, you’ll need a higher grade of iron. If it’s more for lighter tasks, you may select another type. Take your surroundings into account whenever you are writing. Is it going to be outdoors, subject to weather? Or will it be indoors, sheltered from the elements? And these are large components of your decision. At Pengxin, we are your solution to high-silicon molybdenum ductile iron and will help find a perfect fit for any of your project needs.

Best High-Silicon Molybdenum Ductile Iron Suppliers To Buy Right Now

The search for a source of high-silicon molybdenum ductile iron has not been easy. Begin by researching companies that deal in industrial materials. They usually have a good selection and can offer expert advice. Search online to see potential suppliers. Find reviews and ratings to consider what other customers have said about their experiences. This may help expose which companies are trustworthy.

After that, contact suppliers directly. Ask them about their products. For example, you might be interested in their quality control methods or whether they can tailor orders to your specifications. Reputable suppliers typically are happy to have this information shared. You should also see if they have certifications. These indicate that they comply with specific industry standards, which can make you more confident in the quality of the materials you are purchasing.

Here’s another tip go to trade shows or industry seminars. These are great chances to interact with suppliers in person. You can view and ask questions about their products close-up. And you get to learn about new material trends always a perk. We attend a number of industry events at Pengxin, where we can meet with customers and display our high-silicon molybdenum ductile iron. In this manner, you can be certain that you may be dealing with a company which cares about high quality and consumer satisfaction.

Typical Application Problems in High Silicon - Molybdenum Ductile Iron and Solutions to Avoid Them

High-silicon molybdenum ductile iron products is a specific type of metal used for various machines and parts. “But there are some generic issues that people encounter while using it. One problem: This variety of iron can be challenging to cast. Casting is when liquid metal is poured into a mold to form it. If a mold isn’t made right, iron can crack or get weak spots. Otherwise, you'll want to use strong molds to prevent this. Proper heating is also crucial. If the iron is not adequately heated, it will flow imperfectly into the mold. In the other hand, when it’s too hot, some of its strength could be removed.

Another problem is the quantity of silicon added to the iron. While silicon contributes to strength and bend-ability, too much of it can make the iron brittle. What that means is it can be more readily broken under pressure. To prevent this, the right recipe must be followed when blending the iron. Whenever to do something, just stick to the Rules recommended by professionals such as Pengxin when you want good results.

Finally, the setting in which the iron is employed can also create issues. It can rust, for example, if it is given too much exposure to moisture. Therefore, to avoid a situation like this one you should think about using protective coatings and storing the iron in a dry place. By learning more about these issues and avoiding them, you can help make sure that high-silicon molybdenum ductile iron will work well for your purposes.

Benefits of High-Silicon Molybdenum Ductile Iron in the Manufacture

There are numerous advantages of high-silicon molybdenum ductile iron in production. For one thing, this kind of iron is pretty tough. It is strong enough to bear large loads without breaking. This makes it ideal for components that are expected to withstand pressure, such as gears and machine frames. The high silicon molybdenum ductile iron can work well and has a long service life. This tends to save money over time, as you won’t need to replace parts as frequently.

Another benefit is flexibility. This iron is bendable and mold, not crack. That’s a key for fabricating complex parts with matching pieces that have to fit together properly. If a component is too stiff, it risks breaking during use. But with high-silicon molybdenum ductile iron parts can be created that strike the balance of strength and flexibility.

High-silicon molybdenum ductile iron also has a very good heat resistance. That means it won’t warp or lose its strength when it gets sizzling hot. Machines can generate a lot of heat while they are in use in many industries. That temperature is within this type of iron’s ability to cope without difficulty.

Lastly, this iron is designed to withstand the test of time. Meaning it’s not easy to damage, and can be used again and again. For manufacturers like us, this is a huge benefit because it means machines still go and run successfully. Enterprises such as Pengxin recognize the value of superior materials and high-silicon molybdenum ductile iron often ranks among the best for various manufacturing purposes.

Why High-Silicon Molybdenum Ductile Iron is Perfect for Mechanical Parts

High-silicon Molybdenum ductile iron is suited to be used as a production material of mechanical components such as multi-station gears since: First, it is strong in nature since it is toughly built and can withstand heavy loads and stress. That matters where it comes to components such as axles or engine blocks that they must be rugged. When manufacturers choose this type of iron, they are aware of the fact that the parts will be durable, and they will be able to work quite well.

It is also perfect in this other way, you can shape it to any form. Molybdenum ductile irons are easily cast and machinable with a high percentage of silicon. This enables it to be formed to a definite shape that is required by different components. It may be a simple work or a more complex one but this iron can be shaped to suit such needs.

Moreover, molybdenum high-silicon ductile iron is heat resistant and could be applied to the engines and other conditions where extreme heat is required. It will not bend or dent even at temperatures of up to 500 o F. This is especially important to industries that have many parts, like automotive and aerospace, parts that are frequently left in the hardest environments.

Lastly, the wear resistance of this iron would be a match to machinery. The outcome is the decreasing wear and tear and the possibility of minimizing the repair and replacement expenditures to companies. That is one of the reasons why most manufacturers such as Pengxin have chosen high-silicon molybdenum ductile iron as mechanical parts. It is durable, flexible and strong meaning that you can employ it in a house project like the use of plumbing, water heater connection or installation of appliances.

Table of Contents

- How To Select The Purpose High Silicon Molybdenum Ductile Iron For Best Mechanical Properties

- Best High-Silicon Molybdenum Ductile Iron Suppliers To Buy Right Now

- Typical Application Problems in High Silicon - Molybdenum Ductile Iron and Solutions to Avoid Them

- Benefits of High-Silicon Molybdenum Ductile Iron in the Manufacture

- Why High-Silicon Molybdenum Ductile Iron is Perfect for Mechanical Parts